Are you gearing up for a career in Chiller Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chiller Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

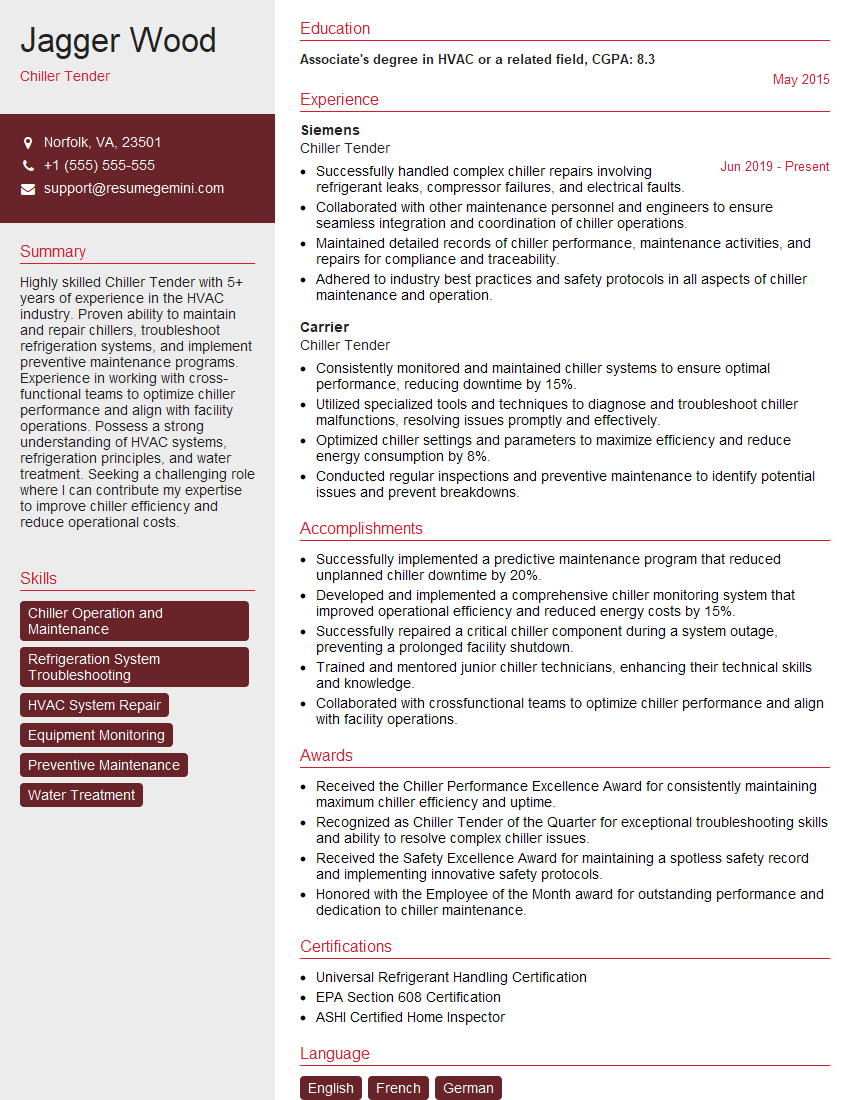

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chiller Tender

1. How do you ensure the efficient and reliable functioning of chillers?

- Regularly inspect and clean the chiller components, including the condenser, evaporator, compressor, and refrigerant lines.

- Monitor chiller performance parameters such as temperature, pressure, and flow rates to identify and address any potential issues.

- Perform preventative maintenance tasks such as oil changes, filter replacements, and refrigerant top-ups to maintain optimal chiller operation.

- Troubleshoot and resolve chiller malfunctions promptly to minimize downtime and maintain a stable cooling environment.

- Maintain accurate maintenance records and documentation to track chiller performance and identify any recurring problems.

2. What are the key safety precautions to observe when working with chillers?

Personal Protective Equipment (PPE):

- Always wear appropriate PPE, including gloves, safety glasses, and protective clothing, to minimize exposure to refrigerants and other hazardous substances.

Refrigerant Handling:

- Handle refrigerants with caution and follow all safety protocols, including using proper tools and equipment.

- Ensure adequate ventilation to avoid inhaling refrigerant vapors, which can be harmful to health.

Electrical Hazards:

- Always de-energize the chiller before performing any maintenance or repairs to avoid electrical shock.

- Inspect electrical components regularly and have them serviced by qualified electricians as needed.

3. How do you prioritize tasks and manage multiple responsibilities as a Chiller Tender?

- Establish a daily work schedule and prioritize tasks based on their urgency and importance.

- Delegate responsibilities to team members or seek assistance from supervisors when necessary to ensure all tasks are completed efficiently.

- Use checklists and maintenance logs to track progress and ensure that all essential tasks are addressed.

- Communicate regularly with supervisors and colleagues to stay informed and coordinate efforts.

- Stay adaptable and flexible to handle unexpected events or changes in workload.

4. Describe your experience in troubleshooting and resolving common chiller issues.

- Overheating: Inspect condenser coils for dirt or debris, clean as necessary. Check refrigerant levels and top up if required.

- Low cooling capacity: Check evaporator coils for frost buildup, clean if needed. Inspect refrigerant charge and adjust if necessary.

- Refrigerant leaks: Use refrigerant detectors to identify leaks and repair or replace damaged components as required.

- Compressor problems: Listen for unusual noises or vibrations, inspect oil levels, and consider seeking professional assistance if necessary.

- Electrical faults: Inspect wiring, connections, and switches. Seek assistance from an electrician if required.

5. Explain the importance of routine maintenance for chillers and describe your approach to preventive maintenance.

- Improved efficiency and performance: Regular maintenance helps maintain optimal chiller operation, reducing energy consumption and increasing cooling capacity.

- Extended equipment lifespan: By addressing minor issues early on, preventive maintenance helps prevent major breakdowns and extends the life of the chiller.

- Reduced downtime: Regular servicing and inspections minimize the risk of unexpected failures, ensuring continuous cooling and minimizing production disruptions.

- Enhanced safety: Routine maintenance helps identify and address potential safety hazards, such as refrigerant leaks or electrical faults.

- Compliance with regulations: Preventive maintenance is often required by industry regulations and standards to ensure the safe and efficient operation of chillers.

6. What are the environmental considerations and regulations related to chiller operation?

- Refrigerant management: Chillers use refrigerants, which can harm the environment if released. Proper handling, storage, and disposal of refrigerants are crucial.

- Energy efficiency: Chiller operation consumes significant energy. Selecting energy-efficient chillers and implementing energy-saving practices minimizes environmental impact.

- Noise pollution: Chillers can generate noise. Proper placement and sound attenuation measures help reduce noise pollution and comply with environmental regulations.

- Water conservation: Some chillers use water for cooling. Implementing water-saving measures, such as using closed-loop systems, reduces water consumption and conserves natural resources.

- Compliance with regulations: It is essential to adhere to local and national environmental regulations governing chiller operation, including those related to refrigerant management, energy efficiency, and noise pollution.

7. How do you handle emergency situations involving chillers?

- Assess the situation: Quickly evaluate the situation to identify the cause of the emergency and potential risks.

- Isolate the chiller: If possible, isolate the chiller from the system to prevent further damage or harm.

- Notify relevant personnel: Inform supervisors, maintenance personnel, and emergency responders if necessary.

- Follow safety protocols: Adhere to established safety protocols and wear appropriate PPE when handling emergencies.

- Document the incident: Record the details of the emergency, including the cause, actions taken, and any injuries or damage.

8. Describe your experience in using chiller monitoring and control systems.

- Data monitoring: Use sensors and monitoring systems to collect and track data on chiller performance, including temperature, pressure, flow rates, and energy consumption.

- Alarm notifications: Configure alarm systems to notify of abnormal conditions, such as high temperatures, low refrigerant levels, or equipment failures.

- Remote access and control: Utilize remote access tools to monitor and control chillers remotely, allowing for proactive maintenance and troubleshooting.

- Trending and analysis: Analyze data trends to identify potential issues early on and optimize chiller performance.

- Report generation: Generate reports on chiller performance, maintenance activities, and energy consumption for analysis and decision-making.

9. How do you stay updated on the latest industry best practices and technological advancements related to chillers?

- Attend industry conferences and workshops: Participate in events to learn about new technologies, trends, and regulations.

- Read industry publications and technical journals: Stay informed about the latest research, case studies, and best practices.

- Network with industry professionals: Connect with colleagues, attend industry events, and exchange knowledge.

- Engage in continuing education: Pursue certifications or training programs to enhance technical skills and knowledge.

- Utilize online resources: Access online forums, webinars, and manufacturer websites for information and updates.

10. Describe your ideal work environment and how it aligns with the requirements of a Chiller Tender role.

- Technical and hands-on: I thrive in environments that challenge me technically and provide opportunities for hands-on problem-solving.

- Team-oriented: I am an effective team player and enjoy collaborating with others to achieve common goals.

- Safety-conscious: Safety is paramount to me, and I prioritize following established protocols and maintaining a safe work environment.

- Results-driven: I am motivated by achieving results and take pride in ensuring the efficient and reliable operation of chillers.

- Continuous improvement: I am committed to ongoing learning and improvement, seeking opportunities to enhance my skills and knowledge in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chiller Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chiller Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chiller Tenders are responsible for the operation and maintenance of chillers, which are used to cool water and other liquids in industrial, commercial, and residential settings.

1. Operation

Chiller Tenders are responsible for monitoring the operation of chillers, identifying potential problems, and maintaining the chiller’s performance at optimal levels. They may also be responsibile for starting, stopping, and adjusting the chiller’s settings as needed.

- Monitor the chiller for leaks, vibrations, and other signs of potential problems.

- Maintain the chiller’s temperature and pressure within the specified range.

- Adjust the chiller’s settings as needed to ensure the proper flow and temperature of the chilled water.

2. Maintenance

Chiller Tenders are responsible for performing routine maintenance on chillers, including cleaning, lubrication, and replacing filters. They may also be responsible for more complex repairs and troubleshooting.

- Clean the chiller’s condenser and evaporator coils regularly.

- Lubricate the chiller’s moving parts as needed.

- Replace the chiller’s filters as needed.

- Troubleshoot and repair the chiller as needed.

3. Safety

Chiller Tenders are responsible for following safety procedures when operating and maintaining chillers. This includes wearing the proper safety gear and following proper lockout/tagout procedures.

- Wear the proper safety gear, such as gloves, safety glasses, and earplugs.

- Follow proper lockout/tagout procedures when performing maintenance on the chiller.

- Be aware of the potential hazards of working with chillers, such as the risk of electrical shock and exposure to hazardous chemicals.

4. Compliance

Chiller Tenders are responsible for ensuring that the chiller is operated and maintained in compliance with all applicable regulations and standards.

- Maintain the chiller in compliance with all applicable regulations and standards.

- Keep records of all maintenance and repairs performed on the chiller.

- Report any potential safety hazards to the appropriate supervisor.

Interview Tips

Here are some tips for preparing for an interview for a Chiller Tender position:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications.

- Visit the company’s website and read about their mission, values, and products/services.

- Research the specific position you are applying for.

- Look for news articles and other information about the company to get a sense of their recent developments and challenges.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly during the interview.

- Use the STAR method to answer interview questions.

- Be prepared to talk about your experience, skills, and qualifications.

- Practice answering questions about your strengths and weaknesses.

3. Prepare questions to ask the interviewer

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for the interview and to arrive on time. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be on time for the interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chiller Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!