Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chimney Construction Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chimney Construction Supervisor so you can tailor your answers to impress potential employers.

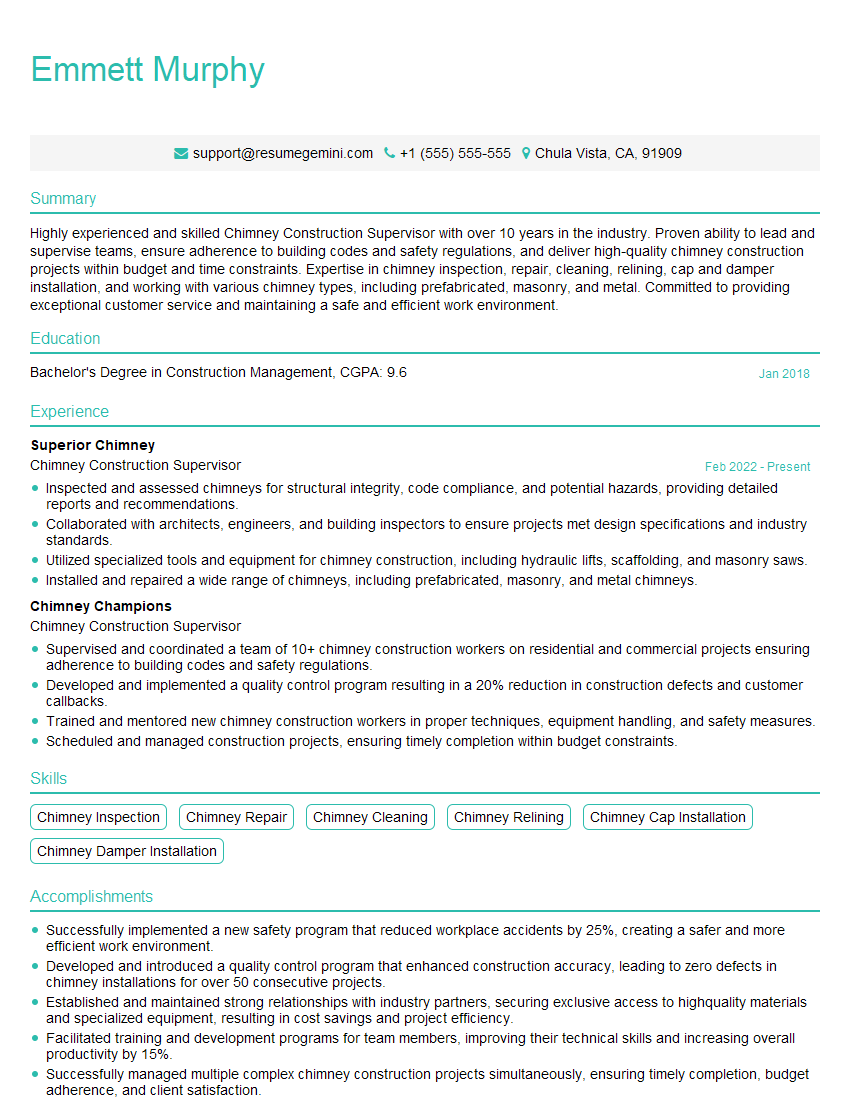

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chimney Construction Supervisor

1. What are the different types of chimneys, and what are their advantages and disadvantages?

There are three main types of chimneys:

- Masonry chimneys are made of brick or stone and are the most common type of chimney. They are durable and can last for centuries, but they can also be expensive to build and repair.

- Metal chimneys are made of metal, such as stainless steel or aluminum. They are lightweight and easy to install, but they can be more expensive than masonry chimneys and are not as durable.

- Prefabricated chimneys are made of pre-fabricated sections that are assembled on site. They are less expensive than masonry chimneys and are easy to install, but they are not as durable.

2. What are the different factors that affect the design of a chimney?

Structural considerations

- The height and weight of the chimney

- The type of soil the chimney will be built on

- The wind and seismic loads the chimney will be subjected to

Performance considerations

- The type of fuel that will be burned in the fireplace or stove

- The efficiency of the fireplace or stove

- The desired draft

Aesthetic considerations

- The style of the house

- The materials used to build the chimney

- The color and finish of the chimney

3. What are the different types of chimney liners, and what are their advantages and disadvantages?

There are three main types of chimney liners:

- Clay liners are the most common type of chimney liner. They are made of fired clay and are durable and fire-resistant. However, they can be damaged by moisture and are not as flexible as other types of liners.

- Metal liners are made of metal, such as stainless steel or aluminum. They are lightweight and flexible, but they can be more expensive than clay liners and are not as durable.

- Prefabricated liners are made of pre-fabricated sections that are assembled on site. They are less expensive than clay liners and are easy to install, but they are not as durable.

4. What are the different methods of chimney construction?

- Traditional masonry construction involves building the chimney from the ground up using bricks or stones.

- Prefabricated chimney construction involves assembling the chimney from pre-fabricated sections.

- Insulated chimney construction involves building the chimney with an insulated liner to improve efficiency and reduce heat loss.

5. What are the different types of chimney caps, and what are their advantages and disadvantages?

There are three main types of chimney caps:

- Standard chimney caps are the most common type of chimney cap. They are made of metal and are designed to keep rain and debris out of the chimney.

- Animal chimney caps are designed to keep animals out of the chimney. They are made of metal or plastic and have a mesh screen to prevent animals from entering the chimney.

- Spark arrestor chimney caps are designed to prevent sparks from escaping from the chimney. They are made of metal and have a mesh screen to catch sparks.

6. What are the different types of chimney flashing, and what are their advantages and disadvantages?

There are three main types of chimney flashing:

- Step flashing is the most common type of chimney flashing. It is made of metal and is installed in steps around the chimney.

- Counter flashing is installed on top of the step flashing and helps to prevent water from leaking into the chimney.

- Base flashing is installed at the base of the chimney and helps to prevent water from leaking into the chimney.

7. What are the different types of chimney maintenance, and what are their advantages and disadvantages?

- Regular chimney cleaning is the most important type of chimney maintenance. It helps to remove soot and debris from the chimney and prevent chimney fires.

- Chimney inspections are important for identifying potential problems with the chimney, such as cracks or damage to the liner.

- Chimney repairs are necessary to fix any problems with the chimney, such as repairing cracks or replacing the liner.

8. What are the different types of chimney safety devices, and what are their advantages and disadvantages?

- Carbon monoxide detectors are important for detecting carbon monoxide leaks from the chimney.

- Smoke detectors are important for detecting smoke from a chimney fire.

- Chimney caps are important for keeping rain and debris out of the chimney.

9. What are the different types of chimney codes and standards, and what are their requirements?

There are a number of different chimney codes and standards, including:

- The International Residential Code (IRC)

- The National Fire Protection Association (NFPA) 211

- The Chimney Safety Institute of America (CSIA)

10. What are the different types of chimney tools and equipment, and what are their uses?

- Chimney brushes are used to clean soot and debris from the chimney.

- Chimney rods are used to connect chimney brushes to the chimney.

- Chimney cameras are used to inspect the inside of the chimney.

- Chimney liners are used to line the inside of the chimney and protect it from damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chimney Construction Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chimney Construction Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chimney Construction Supervisors lead and oversee the construction and maintenance of chimneys, ensuring that projects are completed according to specifications, safety regulations, and industry standards. Their responsibilities encompass:

1. Project Planning and Coordination

Planning and organizing chimney construction projects, including scheduling, material sourcing, and resource allocation.

2. Supervision of Construction Teams

Supervising and directing crews of masons, laborers, and other personnel involved in chimney construction.

3. Ensuring Compliance with Safety Protocols

Enforcing safety protocols and adhering to industry regulations to maintain a safe work environment.

4. Inspection and Quality Control

Inspecting completed chimney structures and ensuring they meet quality standards and specifications.

5. Customer Communication and Consultation

Interacting with clients, architects, and engineers to understand project requirements and provide consultation.

Interview Tips

Preparing for a Chimney Construction Supervisor interview requires thorough research and a well-crafted strategy. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and recent projects. Research industry trends and advancements to demonstrate your knowledge and interest.

2. Highlight Your Experience and Skills

Emphasize your experience in chimney construction, including project management, safety supervision, and quality control. Quantify your accomplishments with specific examples.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your experience, skills, and industry knowledge. Practice answering these questions concisely and confidently.

4. Prepare Questions to Ask the Interviewer

Asking relevant questions about the company, the project, and the team demonstrates your interest and engagement. This also provides an opportunity to clarify any details.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for the interview to show respect and demonstrate your seriousness about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chimney Construction Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.