Are you gearing up for an interview for a Chip Applying Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chip Applying Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

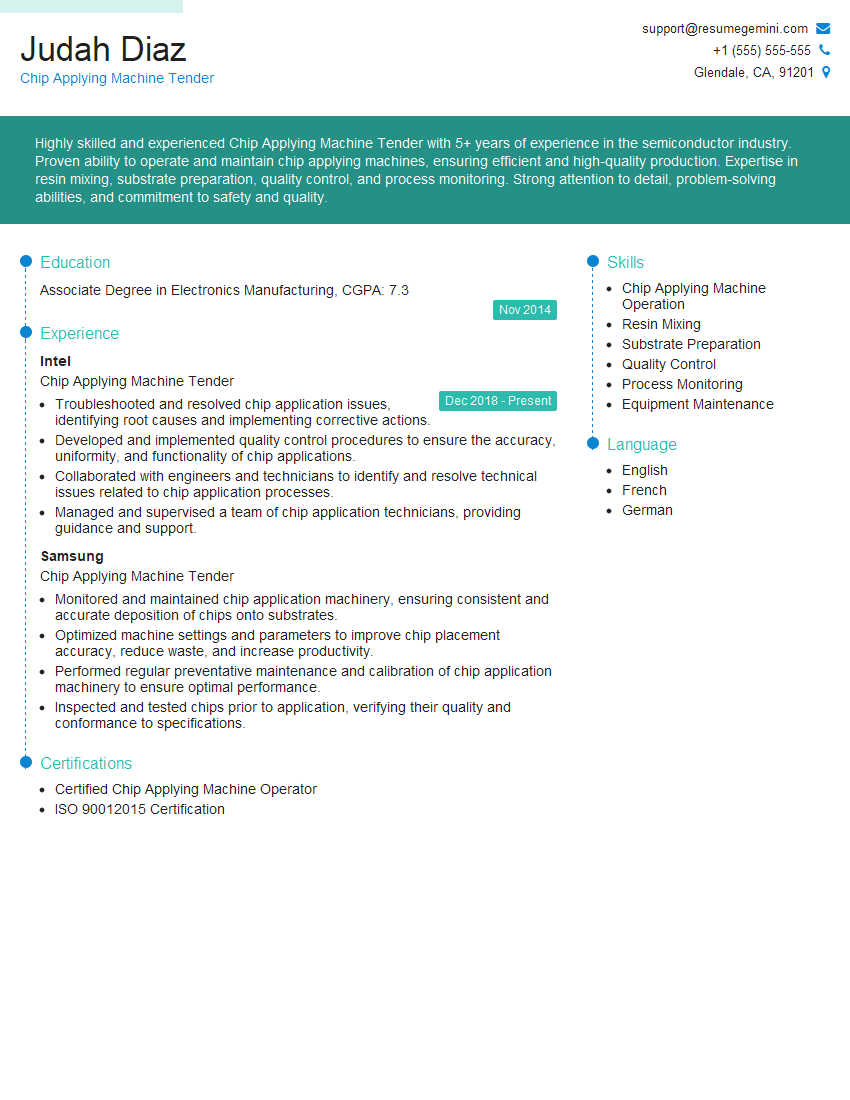

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chip Applying Machine Tender

1. Describe the process of chip application on a PCB using a machine.

The process of chip application on a PCB using a machine involves several steps:

- Preparing the PCB: The PCB must be cleaned and prepared to ensure proper adhesion of the chip.

- Selecting the Chip: The correct chip is selected based on the design specifications.

- Applying Flux: Flux is applied to the PCB to enhance the soldering process.

- Placing the Chip: The chip is accurately placed on the PCB using a pick-and-place machine.

- Reflow Soldering: The PCB is heated to a specific temperature to melt the solder paste and create a strong connection between the chip and the PCB.

- Inspection: The finished PCB is inspected to ensure proper placement and soldering of the chip.

2. What are the different types of chip applying machines and their applications?

Manual Chip Applying Machines

- Used for low-volume production or prototyping.

- Require manual placement of chips, which can be time-consuming.

Semi-Automatic Chip Applying Machines

- Provide a balance between speed and affordability.

- Use a pick-and-place head to automate chip placement.

Fully Automatic Chip Applying Machines

- Used for high-volume production.

- Highly automated, including chip selection, placement, and soldering.

3. How do you set up and calibrate a chip applying machine for different chip sizes and types?

Setting up and calibrating a chip applying machine involves the following steps:

- Selecting the Correct Nozzles: Choose nozzles that match the size and type of chips being applied.

- Adjusting the Feed Rate: Set the machine to dispense the correct amount of solder paste for the chip size.

- Fine-Tuning the Placement Accuracy: Calibrate the machine’s pick-and-place head to ensure precise chip placement.

- Testing and Verification: Run test runs to verify the machine’s settings and make necessary adjustments.

4. What are the common defects that can occur during chip application and how do you troubleshoot them?

- Solder Bridging: Excess solder can create connections between adjacent chips or pads.

- Tombstoning: Chips can be tilted or lifted off the PCB due to uneven soldering.

- Missing Chips: Chips can be dislodged during the placement or soldering process.

- Poor Solder Joints: Weak or incomplete solder connections can cause electrical failures.

5. What safety precautions should be taken when operating a chip applying machine?

- Wear appropriate protective gear: Safety glasses, gloves, and lab coat to prevent exposure to solder fumes.

- Ensure proper ventilation: Use a fume extractor to remove harmful vapors.

- Handle chemicals carefully: Flux and solder paste contain hazardous materials, requiring proper storage and disposal.

- Follow electrical safety guidelines: Ensure proper grounding and avoid working on live equipment.

6. How do you maintain and troubleshoot a chip applying machine to ensure optimal performance?

Maintaining and troubleshooting a chip applying machine involves:

- Regular Cleaning: Cleaning nozzles, feeders, and work surfaces to prevent contamination.

- Calibrating Sensors: Regularly calibrating sensors to ensure accuracy and precision.

- Inspecting Components: Checking nozzles, feeders, and other components for wear or damage.

- Troubleshooting: Diagnosing and resolving common issues, such as nozzle clogs or placement errors.

7. What are the latest advancements in chip applying technology and how are they improving the process?

- High-Speed Nozzles: Advanced nozzles enable faster placement rates, increasing productivity.

- Vision Inspection Systems: Cameras and software inspect chips before and after placement, ensuring accuracy.

- Laser Soldering: Laser technology provides precise and controlled soldering, improving joint quality.

- Smart Factory Integration: Machines can be integrated with factory automation systems for improved efficiency.

8. How do you stay updated with the latest industry trends and advancements in chip applying technology?

- Attending Industry Events: Participating in conferences and trade shows to learn about new technologies.

- Reading Technical Publications: Staying informed through industry journals and white papers.

- Online Research: Utilizing online resources and forums to stay current with industry developments.

- Networking with Professionals: Connecting with experts in the field for knowledge sharing.

9. Describe a particularly challenging project you worked on as a Chip Applying Machine Tender.

In a previous role, I encountered a challenging project involving the application of high-density chips on a complex PCB.

- Precision Placement: The chips were extremely small and required precise placement.

- Bridging Prevention: The design had dense traces, making it crucial to prevent solder bridging.

- High Volume Production: The project demanded a high production rate to meet customer deadlines.

To overcome these challenges, I:

- Optimized Machine Settings: Fine-tuned the machine’s nozzles and feed rate to achieve accurate placement.

- Implemented Inspection System: Integrated an inline vision inspection system to detect bridging and other defects.

- Worked with Engineers: Collaborated with design engineers to optimize the PCB layout for better reworkability.

Through careful planning and execution, we successfully produced the PCBs with high quality and met the project’s demanding specifications.

10. What are your strengths and weaknesses as a Chip Applying Machine Tender?

Strengths:

- Technical Expertise: Proficient in operating and troubleshooting chip applying machines.

- Quality Assurance: Strong attention to detail and commitment to producing high-quality PCBs.

- Process Optimization: Ability to analyze processes and implement improvements for efficiency.

Weaknesses:

- Limited Experience with Advanced Technologies: Less experience with the latest advancements in chip applying technology.

- Time Management: Occasional struggles with managing multiple tasks during peak production.

I am actively working on addressing these weaknesses through training and continuous learning.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chip Applying Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chip Applying Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chip Applying Machine Tenders operate machines that apply coatings to various surfaces. These coatings can be used for a variety of purposes, such as protecting the surface from corrosion or wear, or providing a decorative finish. Chip Applying Machine Tenders are responsible for ensuring that the machines are properly set up, operated, and maintained, and that the coatings are applied in a consistent and uniform manner. Some of the key responsibilities of a Chip Applying Machine Tender include:

1. Setup and operation of chip applying machines

Chip Applying Machine Tenders are responsible for setting up and operating chip applying machines. This involves ensuring that the machine is properly calibrated and adjusted, and that the correct materials and coatings are being used. Chip Applying Machine Tenders must also be able to monitor the machine during operation and make adjustments as needed to ensure that the coating is being applied correctly.

- Set up and calibrate chip applying machines according to specifications.

- Load and unload materials and coatings into the machine.

- Monitor the machine during operation and make adjustments as needed.

2. Maintenance of chip applying machines

Chip Applying Machine Tenders are also responsible for maintaining chip applying machines. This involves cleaning and lubricating the machine, and inspecting it for wear and tear. Chip Applying Machine Tenders must be able to identify and repair minor problems, and they must also be able to troubleshoot more complex problems and contact a mechanic if necessary.

- Clean and lubricate chip applying machines.

- Inspect machines for wear and tear.

- Identify and repair minor problems.

- Troubleshoot more complex problems and contact a mechanic if necessary.

3. Quality control of coated surfaces

Chip Applying Machine Tenders are responsible for ensuring that the coatings applied to surfaces are of a high quality. This involves visually inspecting the surfaces for defects, and testing the coatings to ensure that they meet the required specifications. Chip Applying Machine Tenders must also be able to identify and correct any problems that may occur during the coating process.

- Visually inspect coated surfaces for defects.

- Test coatings to ensure that they meet the required specifications.

- Identify and correct any problems that may occur during the coating process.

4. Safety and environmental compliance

Chip Applying Machine Tenders must be aware of the safety and environmental regulations that apply to their work. This includes knowing how to safely operate chip applying machines, and how to properly dispose of hazardous materials. Chip Applying Machine Tenders must also be able to identify and assess potential hazards, and take steps to mitigate these hazards.

- Follow all safety and environmental regulations.

- Safely operate chip applying machines.

- Properly dispose of hazardous materials.

- Identify and assess potential hazards.

- Take steps to mitigate potential hazards.

Interview Tips

Preparing for an interview for a Chip Applying Machine Tender position can be daunting, but following these tips can help you ace the interview and land the job.

1. Before the interview

Before the interview, it is important to do your research on the company and the position. This will help you understand the company’s culture and values, and it will also help you answer interview questions in a way that is relevant to the position.

- Research the company and the position.

- Practice answering common interview questions.

- Dress professionally and arrive on time for the interview.

2. During the interview

During the interview, it is important to be yourself and to answer the questions honestly and concisely. Be sure to highlight your skills and experience, and explain how you can contribute to the company. It is also important to ask questions about the company and the position, as this shows that you are interested in the opportunity and that you are serious about the interview.

- Be yourself and answer the questions honestly and concisely.

- Highlight your skills and experience.

- Explain how you can contribute to the company.

- Ask questions about the company and the position.

3. After the interview

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are serious about the opportunity. You can follow up by email or by phone, and you should thank the interviewer for their time.

- Follow up with the interviewer after the interview.

- Thank the interviewer for their time.

- Reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chip Applying Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!