Are you gearing up for an interview for a Chip Mixing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chip Mixing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

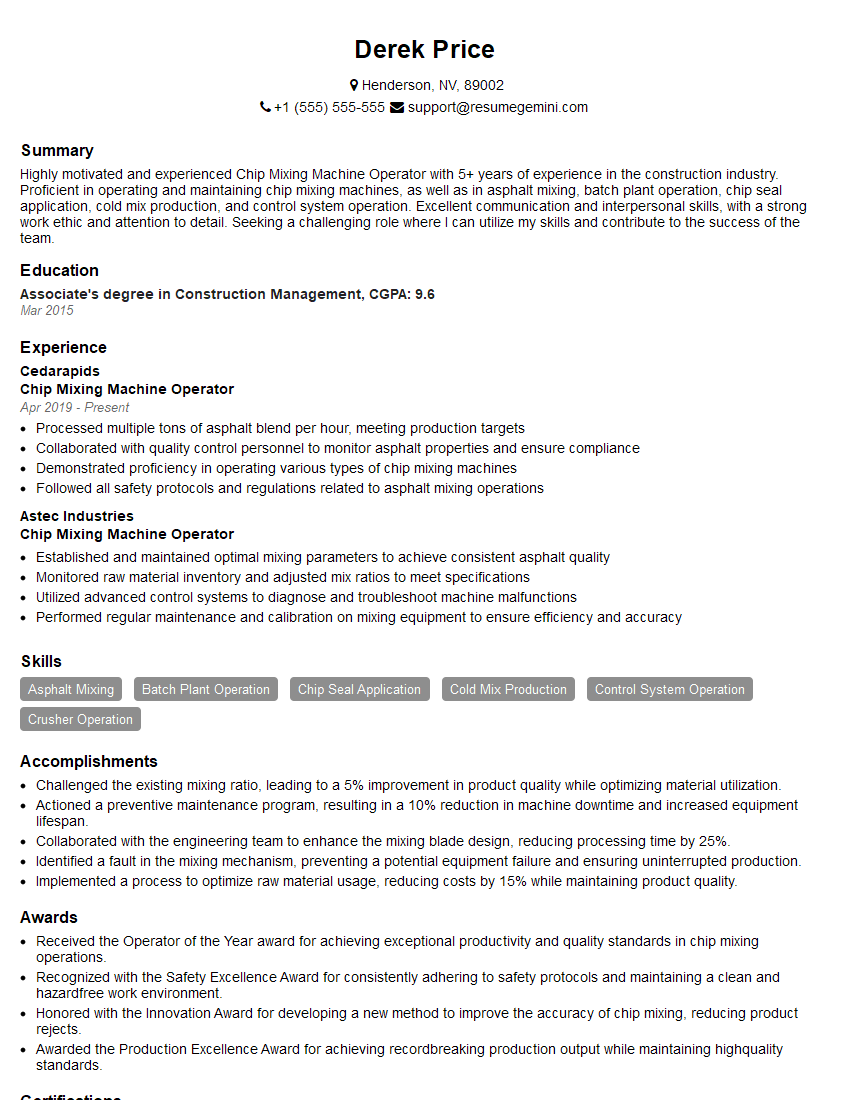

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chip Mixing Machine Operator

1. Explain the process of chip mixing in detail.

The process of chip mixing involves combining different types of chips to create a desired blend. It typically involves the following steps:

- Selecting the chips: The first step is to select the appropriate chips based on the desired blend. This includes determining the type, size, and quantity of each chip.

- Weighing the chips: Each type of chip is weighed to ensure the correct proportions for the blend.

- Loading the chips: The weighed chips are then loaded into the chip mixing machine.

- Mixing the chips: The machine mixes the chips thoroughly to create a uniform blend.

- Discharging the blend: Once the chips are mixed, they are discharged from the machine and stored or used as needed.

2. Describe the different types of chip mixing machines.

There are several types of chip mixing machines available, each with its own characteristics:

Batch mixers

- Mix a specific batch of chips at a time.

- Suitable for small to medium-sized batches.

Continuous mixers

- Mix chips continuously in a flow-through process.

- Ideal for large-scale operations.

Paddle mixers

- Use paddles to mix the chips.

- Suitable for gentle mixing of delicate materials.

Ribbon mixers

- Use spiral ribbons to mix the chips.

- Provide a high level of mixing efficiency.

3. What are the key factors to consider when selecting a chip mixing machine?

When selecting a chip mixing machine, several key factors should be considered:

- Capacity: The size and capacity of the machine should meet the required production volume.

- Mixing efficiency: The machine should provide thorough and uniform mixing of the chips.

- Type of chips: The machine should be compatible with the type of chips being mixed.

- Ease of operation and maintenance: The machine should be user-friendly and easy to maintain.

- Cost: The cost of the machine should be within the budget.

4. Explain how to calibrate a chip mixing machine.

Calibrating a chip mixing machine involves adjusting its settings to ensure accurate mixing:

- Load the machine with a known weight of chips.

- Run the machine for a specified period.

- Discharge the chips and measure their weight.

- Compare the measured weight to the known weight.

- Adjust the machine’s settings as needed to achieve the desired mixing ratio.

5. Describe the safety protocols that should be followed when operating a chip mixing machine.

To ensure safety when operating a chip mixing machine, the following protocols should be followed:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Ensure that the machine is properly grounded.

- Do not overload the machine.

- Never reach into the machine while it is running.

- Keep the machine clean and free of debris.

6. Explain how to troubleshoot common problems that may occur with a chip mixing machine.

To troubleshoot common problems with a chip mixing machine:

- If the machine is not mixing the chips properly, check the following:

- The machine is properly calibrated.

- The chips are being loaded correctly.

- The machine is not overloaded.

- If the machine is making excessive noise, check the following:

- The machine is properly lubricated.

- There are no loose parts.

- The bearings are not worn.

7. How do you maintain a chip mixing machine to ensure optimal performance?

To maintain a chip mixing machine for optimal performance:

- Clean the machine regularly to remove any debris or dust.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for any wear or damage.

- Calibrate the machine regularly to ensure accurate mixing.

8. Explain the importance of maintaining accurate records when operating a chip mixing machine.

Maintaining accurate records when operating a chip mixing machine is crucial for several reasons:

- To ensure product quality: Records help track the mixing parameters and ensure that the chips are being mixed according to specifications.

- To facilitate troubleshooting: Records can help identify potential problems with the machine or the mixing process.

- To comply with regulations: In some industries, maintaining records is a requirement for regulatory compliance.

9. Describe the different types of chips that can be mixed using a chip mixing machine.

A chip mixing machine can be used to mix a wide variety of chips, including:

- Poker chips

- Casino chips

- Bingo chips

- Plastic chips

- Ceramic chips

- Metal chips

10. Explain how to calculate the mixing ratio for a chip mixing machine.

To calculate the mixing ratio for a chip mixing machine, the following steps should be taken:

- Determine the desired proportions of each type of chip.

- Convert the proportions to weights or volumes.

- Add the weights or volumes of all the chips to get the total weight or volume.

- Divide the weight or volume of each type of chip by the total weight or volume to get the mixing ratio.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chip Mixing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chip Mixing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chip Mixing Machine Operators play a vital role in various industries by managing and operating machines that mix and blend raw materials.

1. Operating and Monitoring Chip Mixing Machine

• Understanding and accurately following established operating procedures for the chip mixing machine

- Maintaining the machine in good working condition through regular inspections and timely maintenance

- Monitoring the mixing process, ensuring the proper mixing of ingredients and controlling the machine’s settings

2. Material Handling

• Loading raw materials into the mixing machine and unloading the mixed product

- Handling materials safely and efficiently, adhering to established protocols

- Identifying and addressing any issues with the material flow or quality

3. Quality Control

• Conducting quality checks on the mixed product to ensure it meets specifications

- Sampling and testing the mixed product, interpreting results, and taking corrective actions as needed

- Maintaining detailed records of the mixing process and quality control checks

4. Safety and Compliance

• Observing and adhering to established safety guidelines, including wearing appropriate protective gear

- Following environmental regulations and maintaining a clean and organized work environment

- Reporting any safety hazards or spills immediately to the supervisor or relevant personnel

5. Communication and Collaboration

• Communicating effectively with supervisors and colleagues to ensure smooth operation and resolve issues

- Collaborating with maintenance personnel to address machine issues and ensure timely repairs

- Participating in training sessions and knowledge-sharing activities to enhance skills and stay updated on industry best practices

Interview Tips

Interviews can be nerve-wracking, but preparing well can boost your confidence and increase your chances of success. Here are some tips to help you ace your Chip Mixing Machine Operator interview:

1. Research the Company and Position

• Thoroughly research the company’s industry, values, and specific products or services.

- Visit their website, read their social media pages, and check out any relevant news articles.

- Carefully review the job description to understand the key responsibilities and qualifications required.

2. Practice Answering Common Interview Questions

• Prepare for common interview questions, such as:

- Tell me about your experience operating chip mixing machines.

- How do you ensure the quality of the mixed product?

- Describe a time you faced a challenge while operating the mixing machine and how you resolved it.

3. Showcase Your Skills and Experience

• Highlight your skills and experience that are relevant to the job.

- Emphasize your ability to operate chip mixing machines efficiently and maintain them in good condition.

- Provide examples of how you have ensured the quality of mixed products through effective quality control measures.

4. Prepare Questions for the Interviewer

• Prepare thoughtful questions to ask the interviewer at the end of the session.

- This demonstrates your interest in the position and the company.

- Consider asking about the company’s growth plans, sustainability initiatives, or the training opportunities available.

5. Follow Up

• After the interview, send a thank-you note to the interviewer within 24 hours.

- Express your appreciation for their time and reiterate your interest in the position.

- If possible, mention something specific you discussed during the interview that you found particularly interesting.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chip Mixing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!