Are you gearing up for an interview for a Chipper Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chipper Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

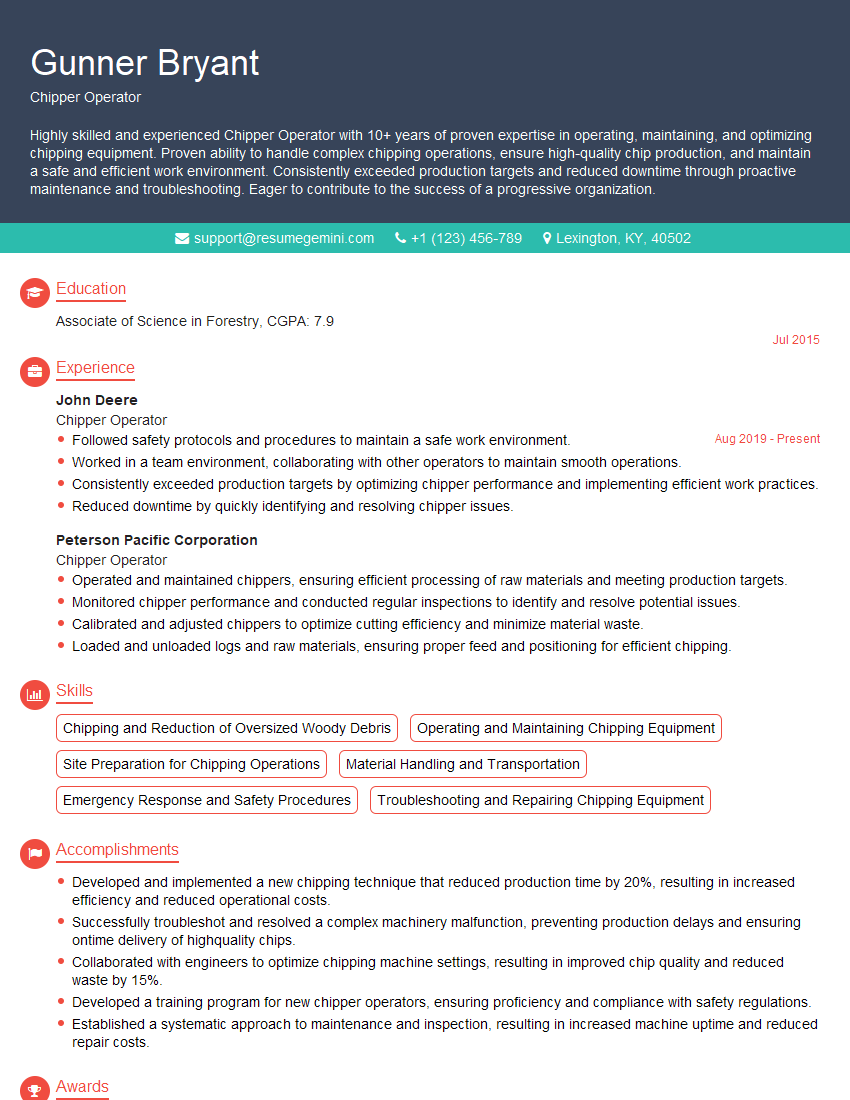

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chipper Operator

1. Describe the primary responsibilities of a Chipper Operator?

As a Chipper Operator, I would be responsible for various tasks, including:

- Operating a chipper machine to process wood materials into chips

- Loading and unloading logs, branches, and other wood materials onto the chipper

- Ensuring that the chipper is properly maintained and adjusted for optimal performance

- Monitoring the chipper during operation to ensure safety and efficiency

- Performing routine maintenance and troubleshooting as needed

2. Explain the safety precautions that must be taken when operating a chipper?

Personal Protective Equipment

- Wear appropriate safety gear, including hard hat, safety glasses, gloves, earplugs, and protective clothing

- Ensure that all clothing is tight-fitting and free from loose ends that could get caught in the machine

Machine Operation

- Inspect the chipper thoroughly before each use, checking for any defects or damage

- Never operate the chipper without proper guards and safety devices in place

- Keep a safe distance from the chipper’s discharge chute and never reach into the machine while it is running

- Be aware of the surrounding area and ensure that no one is in the vicinity of the chipper before starting operation

- Follow all manufacturer’s instructions and safety guidelines for the specific chipper model being used

3. What types of wood materials can be processed in a chipper?

A chipper can process a wide range of wood materials, including:

- Logs and branches of various sizes

- Lumber scraps and offcuts

- Wood pallets

- Cardboard and paper products

- Brush and other woody vegetation

4. Describe the different types of chippers and their applications.

- Drum Chippers: Large, industrial-grade chippers with a rotating drum equipped with cutting blades; used for processing large logs and branches into coarse chips

- Disc Chippers: Compact chippers with a rotating disc equipped with cutting knives; used for processing smaller wood materials into finer chips

- Knife Chippers: Heavy-duty chippers with a set of stationary knives that cut against a rotating anvil; used for producing uniform-sized chips for specific applications

- Brush Chippers: Specialized chippers designed for processing brush and other woody vegetation; typically used for land clearing and maintenance

5. What factors should be considered when selecting a chipper for a particular application?

- Material to be Processed: Type, size, and quantity of wood materials to be chipped

- Capacity and Production Rate: Required output volume and desired chip size

- Power Requirements: Availability and type of power source (electric, diesel, etc.)

- Budget and Operational Costs: Purchase price, maintenance expenses, and fuel consumption

- Safety Features: Compliance with safety standards and availability of safety devices

6. Explain the process of calibrating a chipper to produce chips of a specific size?

Calibrating a chipper involves adjusting the clearance between the cutting blades and the anvil or bedknife.

- Measure the desired chip size

- Loosen the locking mechanisms on the adjustable components

- Use shims or spacers to adjust the clearance accordingly

- Tighten the locking mechanisms to secure the adjustment

- Run a test batch of material through the chipper to verify the chip size

- Make further adjustments as needed until the desired chip size is achieved

7. What are the common maintenance tasks required for a chipper?

- Daily: Visual inspection, cleaning, and lubrication of moving parts

- Weekly: Blade sharpening or replacement, checking and adjusting drive belts

- Monthly: Thorough cleaning of the machine, including the discharge chute and screen

- Annually: Comprehensive maintenance, including oil changes, filter replacements, and safety inspections

8. Describe the process of troubleshooting a chipper that is not producing chips properly?

- Check for Power: Ensure that the chipper is receiving power and that all connections are secure

- Inspect Blades: Examine the cutting blades for dullness, damage, or misalignment

- Verify Clearance: Check the clearance between the blades and the anvil or bedknife

- Examine Screen: Inspect the discharge screen for clogging or damage

- Check Feed Rate: Adjust the feed rate to ensure that the chipper is not being overloaded

- Inspect Discharge Chute: Ensure that the discharge chute is clear of debris and that the flow of chips is not obstructed

9. How do you ensure the safe and efficient operation of a chipper?

- Follow Safety Procedures: Adhere to all established safety guidelines and wear appropriate protective gear

- Inspect Equipment: Conduct regular inspections of the chipper and its components to identify any potential hazards

- Proper Maintenance: Perform routine maintenance tasks to keep the chipper in optimal working condition

- Training and Supervision: Ensure that all operators are adequately trained and supervised to promote safe work practices

- Emergency Preparedness: Develop an emergency plan and establish clear protocols for handling potential incidents

10. What is your understanding of the environmental regulations related to chipper operations?

- Emission Control: Comply with emission regulations by using chippers equipped with emission control devices

- Noise Control: Implement noise-reduction measures, such as using silencers or operating chippers in designated areas

- Waste Management: Properly dispose of wood chips and other waste materials generated from chipper operations

- Recordkeeping: Maintain accurate records of chipper operations and environmental compliance

- Employee Training: Educate employees on environmental regulations and best practices for sustainable chipper operations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chipper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chipper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

A Chipper Operator assumes several critical responsibilities within the organization, including:

1. Equipment Operation and Maintenance:

Skilled in operating and maintaining wood chippers, ensuring optimal performance and safety.

- Conducts routine inspections and maintenance tasks on chippers, including cleaning, lubrication, and belt adjustments.

- Identifies and troubleshoots mechanical issues, performing necessary repairs or coordinating with maintenance personnel.

2. Material Handling and Processing:

Efficiently manages the flow of wood materials through the chipping process, ensuring production targets are met.

- Loads and unloads wood logs or branches into the chipper, utilizing proper techniques for safe and productive operation.

- Monitors the chipping process, adjusting machine settings and feeding rate to optimize chip quality and yield.

3. Safety and Compliance:

Upholds the highest standards of safety and compliance throughout the chipping operations.

- Strictly adheres to established safety protocols and procedures, wearing appropriate personal protective equipment (PPE) at all times.

- Ensures the work area remains organized and free of hazards, preventing accidents and injuries.

4. Production Monitoring and Reporting:

Meticulously monitors production outputs and reports any deviations or performance issues.

- Tracks chipped material quantities, chip quality, and machine efficiency, identifying areas for improvement.

- Communicates production data and any operational concerns to supervisors for timely decision-making.

5. Teamwork and Collaboration:

Effectively collaborates with team members and other departments, fostering a productive and cooperative work environment.

- Participates in regular safety meetings and training sessions, sharing knowledge and best practices with colleagues.

- Assists with other tasks as needed, demonstrating a commitment to teamwork and overall operational efficiency.

Interview Tips:

To ace the interview for a Chipper Operator position, it is essential to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Role:

Familiarize yourself with the company’s background, industry, and specific requirements for the Chipper Operator role.

- Visit the company website and social media pages to gather information about their operations, values, and culture.

- Thoroughly review the job description to identify the key responsibilities and qualifications expected of a successful candidate.

2. Highlight Your Technical Skills:

Emphasize your proficiency in operating and maintaining wood chippers, including your knowledge of mechanical components and troubleshooting techniques.

- Quantify your experience in operating chippers, providing specific examples of production outputs, chip quality achieved, and any improvements you implemented.

- Showcase your ability to handle routine maintenance tasks and diagnose and resolve common mechanical issues, demonstrating your commitment to equipment uptime.

3. Demonstrate Safety Consciousness:

Convey your unwavering commitment to safety by highlighting your adherence to established protocols and your proactive approach to hazard identification and prevention.

- Provide examples of your involvement in safety training and initiatives, emphasizing your understanding of industry best practices and regulatory requirements.

- Describe how you maintain a clean and organized work area, ensuring the safety of yourself and your colleagues.

4. Prepare for Common Interview Questions:

Anticipate typical interview questions and prepare well-structured answers that showcase your skills and experience.

- Practice answering questions about your equipment operation skills, troubleshooting expertise, and safety procedures.

- Be ready to discuss your teamwork experience, highlighting your ability to collaborate effectively and contribute to a productive work environment.

5. Dress Professionally and Arrive on Time:

Convey professionalism and respect for the interviewer by dressing appropriately and arriving punctually for your interview.

- Choose attire that is clean, pressed, and suitable for the industry and work environment.

- Plan your travel route in advance to avoid any delays and demonstrate your time management skills.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chipper Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chipper Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.