Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chips Screen Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chips Screen Tender so you can tailor your answers to impress potential employers.

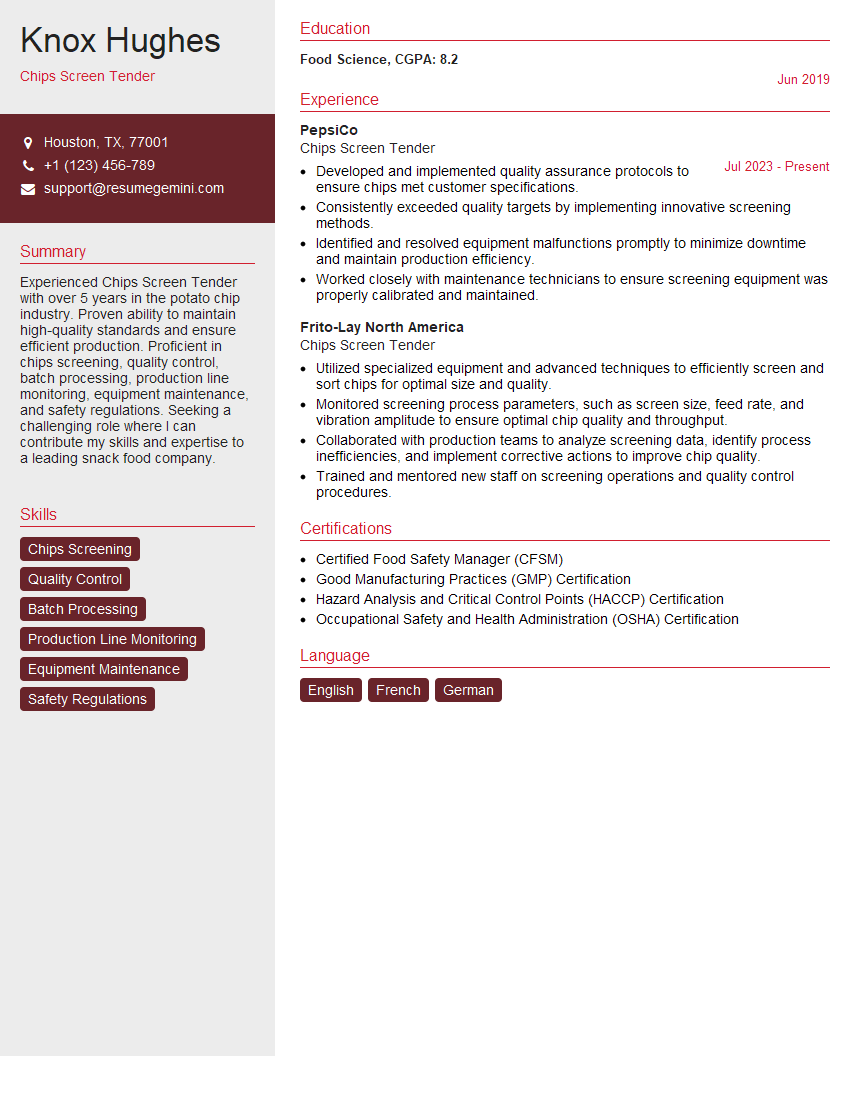

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chips Screen Tender

1. What are the different types of chips screens and their applications?

There are various types of chips screens with diverse applications, including:

- Vibrating screens: Used in coarse screening applications such as scalping, dewatering, and sizing materials.

- Rotary screens: Suitable for fine screening and dewatering, particularly in the mining and quarrying industries.

- Trommel screens: Cylindrical screens used for cleaning, sizing, and scalping materials.

- Grizzly screens: Heavy-duty screens with wide openings for removing large debris and oversize materials.

- Shaker screens: Reciprocating screens used in various industries for screening and separating materials.

2. What factors should be considered when selecting a chips screen?

Capacity and throughput

- Determine the required capacity and throughput of the screen based on the material flow rate.

Material characteristics

- Consider the size, shape, and moisture content of the material being screened.

Screen size and mesh

- Select the appropriate screen size and mesh opening to achieve the desired separation and efficiency.

Screening environment

- Factors such as dust, moisture, and temperature should be considered for proper screen selection.

3. How do you calculate the efficiency of a chips screen?

The efficiency of a chips screen is calculated by determining the percentage of material that passes through the screen in relation to the total material fed into the screen. The formula is:

Efficiency = (Material passed through screen / Total material fed) x 100%

4. What are the common maintenance procedures for chips screens?

- Regular cleaning and inspection of screens to remove debris and blockages.

- Checking and adjusting screen tension to ensure proper screening.

- Lubricating moving parts and replacing worn components as needed.

- Monitoring screen performance and making adjustments to optimize efficiency and prevent breakdowns.

5. Describe the process of troubleshooting a chips screen.

- Identify the problem and its symptoms, such as reduced throughput or poor separation.

- Inspect the screen, check for blockages, damage, or misalignment.

- Review the screening process and adjust parameters such as screen speed or feed rate.

- If necessary, consult with the manufacturer or a qualified technician for further assistance.

6. What are the safety precautions that should be observed when operating a chips screen?

- Wear appropriate personal protective equipment (PPE) such as gloves, eye protection, and hearing protection.

- Lock out and tag out the screen before performing any maintenance or repairs.

- Keep clear of moving parts and avoid touching the screen while it is in operation.

- Follow established safety procedures and protocols as outlined by the manufacturer or workplace.

7. How do you determine the optimal screen mesh size for a given application?

Material characteristics

- Consider the size distribution, shape, and density of the material being screened.

Separation requirements

- Determine the desired separation efficiency and the target particle size range.

Screen type and capacity

- Take into account the type of screen being used and its capacity limitations.

Empirical testing

- Conduct trial runs with different screen sizes to determine the optimal mesh size for the specific application.

8. What are the different methods used to clean chips screens?

Manual cleaning

- Using brushes, scrapers, or water jets to remove debris and blockages.

Ultrasonic cleaning

- Submerging the screen in an ultrasonic bath to dislodge and remove contaminants.

Automated cleaning systems

- Employing spray nozzles, brushes, or other mechanisms to clean the screen while it is in operation.

Chemical cleaning

- Using chemical solutions or detergents to dissolve and remove stubborn deposits or contaminants.

9. How do you determine the wear and tear of a chips screen?

Visual inspection

- Inspect the screen for signs of wear, such as holes, tears, or thinning.

Performance monitoring

- Track the efficiency and throughput of the screen over time to identify any decline in performance.

Maintenance records

- Review maintenance records to assess the frequency and extent of repairs and replacements.

Manufacturer recommendations

- Refer to the manufacturer’s guidelines for expected wear and tear and recommended replacement intervals.

10. What are the key factors to consider when designing a chips screen for a specific application?

Material characteristics

- Understand the size, shape, and flowability of the material being screened.

Separation requirements

- Determine the desired separation efficiency and the target particle size range.

Capacity and throughput

- Calculate the required capacity and throughput of the screen based on the material flow rate.

Screen type and mesh size

- Select the appropriate screen type and mesh size to achieve the desired separation and efficiency.

Environmental factors

- Consider factors such as dust, moisture, and temperature that may impact the screen’s performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chips Screen Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chips Screen Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chips Screen Tender is responsible for the safe and efficient tendering and operation of chip screens used in the production of wood chips.

1. Screen Operation

Operate chip screens to separate wood chips by size and remove oversize chips, sawdust, and other contaminants.

- Monitor screen performance and make necessary adjustments to ensure proper separation.

- Clean and maintain screens regularly to prevent clogging and ensure optimal operation.

2. Material Handling

Unload incoming wood chips from trucks or conveyors and feed chips into the screen.

- Transport separated chips to designated areas or conveyors.

- Maintain a clean and organized work area.

3. Equipment Maintenance

Inspect and maintain chip screens, including lubrication, belt tensioning, and cleaning.

- Perform minor repairs and troubleshoot equipment issues.

- Report and document any equipment malfunctions or maintenance needs.

4. Safety and Compliance

Follow all safety procedures and regulations related to chip screen operation, including lockout/tagout.

- Wear appropriate personal protective equipment (PPE) and maintain a safe work environment.

- Comply with environmental regulations and guidelines.

Interview Tips

To ace an interview for a Chips Screen Tender position, preparing thoroughly is crucial. Consider the following tips:

1. Research and Know the Job

Familiarize yourself with the key job responsibilities outlined above. Research the company and the specific role you are applying for. This will help you demonstrate your understanding of the industry and the position.

- Example: “I understand that the primary responsibility of a Chips Screen Tender is to operate and maintain chip screens to ensure efficient chip separation. I have previous experience in operating similar equipment and am confident in my ability to handle this role.”

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly relate to the job requirements. Focus on skills such as screen operation, material handling, equipment maintenance, and safety procedures.

- Example: “In my previous role, I was responsible for operating and maintaining a chip screen at a sawmill. I consistently met production targets and maintained a safe work environment. I am also proficient in troubleshooting and performing minor repairs.”

3. Demonstrate Safety Awareness

Safety is paramount in the role of a Chips Screen Tender. Emphasize your understanding of safety procedures and your commitment to maintaining a safe work environment.

- Example: “I am fully aware of the safety procedures related to chip screen operation, including lockout/tagout. I always prioritize safety and adhere to all regulations and guidelines.”

4. Prepare Questions

Asking well-informed questions at the end of the interview shows your interest and engagement. Prepare questions related to the specific role, company culture, or industry trends. This demonstrates your initiative and eagerness to learn more.

- Example: “I’m particularly interested in the company’s commitment to sustainability. Could you please elaborate on how chip screen operations align with this initiative?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chips Screen Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!