Feeling lost in a sea of interview questions? Landed that dream interview for Chopped Strand Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chopped Strand Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

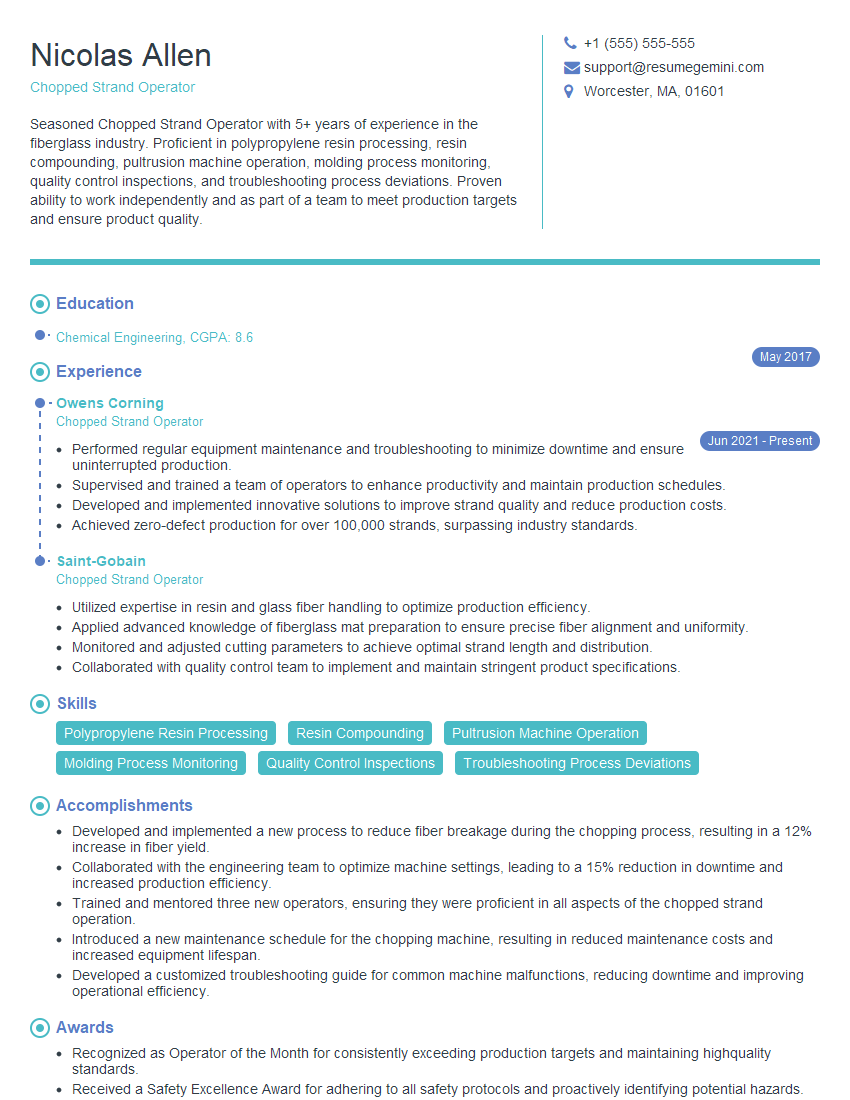

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chopped Strand Operator

1. What are the primary duties and responsibilities of a Chopped Strand Operator?

- Operate and maintain chopped strand machines to cut fiberglass strands to specified lengths.

- Monitor and control process parameters to ensure production meets quality standards.

- Perform routine maintenance and troubleshooting on equipment to minimize downtime.

- Adhere to safety regulations and wear appropriate personal protective equipment (PPE).

- Work effectively in a team environment, following instructions from supervisors.

2. How do you ensure the quality of chopped strands produced?

Calibration and Maintenance

- Calibrate and maintain equipment regularly to ensure accurate strand length and diameter.

- Monitor cutting blades and replace them when necessary to maintain sharpness.

Process Control

- Control process variables such as strand speed, temperature, and resin flow.

- Analyze strand samples to ensure they meet specifications for length, diameter, and resin content.

Inspection and Testing

- Conduct regular inspections of strands to detect defects or inconsistencies.

- Perform quality assurance tests to verify strength, tensile properties, and other performance characteristics.

3. Describe the different types of chopped strand machines you have experience with.

- Horizontal Chopped Strand Machine: Suitable for high-speed production of short strands.

- Vertical Chopped Strand Machine: Used for producing longer strands, with better fiber orientation.

- Direct Roving Chopping Machine: Cuts roving directly into strands, eliminating the need for a roving creel.

- Bobbin-Fed Chopped Strand Machine: Accepts rovings on bobbins, which are then fed through the cutting head.

4. How do you handle potential safety hazards associated with operating chopped strand machines?

- Wear proper PPE including gloves, eye protection, and respiratory mask.

- Keep work area clean and free of debris to prevent slips and falls.

- Follow lockout/tagout procedures when conducting maintenance or repairs.

- Be aware of moving parts and potential pinch points on the machine.

- Report any safety concerns or incidents immediately to supervisors.

5. What are the common troubleshooting steps you take when the chopped strand machine experiences downtime?

- Check for mechanical failures, such as broken blades or worn belts.

- Inspect electrical connections and wiring for loose or damaged components.

- Monitor process parameters to identify any deviations that may be causing issues.

- Clean and lubricate moving parts to reduce friction and prevent overheating.

- Reset the machine and restart the process to resolve minor software glitches.

6. How do you optimize the production efficiency of a chopped strand machine?

- Calibrate the machine to minimize waste and produce consistent strand lengths.

- Maintain equipment regularly to prevent breakdowns and minimize downtime.

- Monitor production rates and identify areas where improvements can be made.

- Experiment with different cutting parameters to find the optimal settings for specific resins and applications.

- Work with suppliers to ensure the quality and consistency of raw materials.

7. Can you describe the different applications of chopped strands in the composites industry?

- Reinforcement in fiberglass-reinforced plastics (FRP) for automotive, marine, and construction industries.

- Additives in concrete and mortar to improve strength and durability.

- Fillers in paints and coatings to enhance toughness and scratch resistance.

- Raw materials for the production of non-woven fiberglass mats and fabrics.

8. What are the challenges commonly encountered in chopped strand production?

- Maintaining consistent strand length and diameter to meet quality standards.

- Preventing fiber breakage and minimizing waste during the cutting process.

- Ensuring the adhesion between fibers and resin to achieve optimal composite properties.

- Dealing with dust and particulate matter generated during strand production.

9. How do you stay updated with the latest advancements in chopped strand technology?

- Attend industry conferences and exhibitions.

- Read technical publications and research papers.

- Consult with manufacturers and suppliers for product updates and innovations.

- Engage in online forums and discussions with other professionals in the field.

10. Why are you interested in working as a Chopped Strand Operator in our company?

- My passion for the composites industry and desire to contribute to the production of high-quality fiberglass products.

- The opportunity to learn from experienced professionals and contribute to the company’s success.

- The company’s reputation for innovation and commitment to quality.

- The chance to work in a challenging and rewarding environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chopped Strand Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chopped Strand Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chopped Strand Operator plays a crucial role in the production of chopped strands, a vital component in the manufacturing of fiberglass and composite materials.

1. Strand Production

The primary responsibility of a Chopped Strand Operator is to operate and monitor the chopped strand machine, ensuring that it produces strands of the correct length and quality.

- Setting up and calibrating the machine according to specifications.

- Feeding raw fiberglass roving into the machine and monitoring the cutting process.

- Adjusting machine parameters to achieve optimal strand length and uniformity.

2. Quality Control and Monitoring

The operator is responsible for maintaining the quality of chopped strands by conducting regular inspections and testing.

- Inspecting strands for defects, such as breaks, uneven cuts, or contamination.

- Taking samples for testing to ensure that the strands meet specifications.

- Identifying and correcting any deviations from quality standards.

3. Equipment Maintenance

The operator is also responsible for the maintenance and upkeep of the chopped strand machine.

- Cleaning and lubricating the machine regularly to prevent breakdowns.

- Performing minor repairs and troubleshooting if necessary.

- Reporting any major issues or equipment malfunctions to supervisors.

4. Safety and Compliance

The operator is responsible for adhering to all safety regulations and procedures.

- Wearing appropriate protective gear, such as gloves, safety glasses, and hearing protection.

- Following established safety protocols for handling fiberglass roving and chemicals.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Chopped Strand Operator position, candidates should prepare thoroughly and demonstrate their skills and knowledge in the following areas:

1. Technical Skills

Candidates should be proficient in the operation and maintenance of chopped strand machines. They should also have a strong understanding of fiberglass roving and the production process.

- Highlight your experience in operating and calibrating chopped strand machines.

- Discuss your knowledge of fiberglass roving properties and cutting techniques.

- Provide examples of how you have identified and resolved equipment malfunctions.

2. Quality Control and Inspection

The ability to ensure the quality of chopped strands is crucial. Candidates should emphasize their expertise in inspection techniques and quality control measures.

- Explain your experience in conducting inspections and testing chopped strands.

- Describe how you have identified and corrected defects in the production process.

- Discuss your understanding of quality standards and specifications.

3. Safety and Compliance

Adherence to safety regulations is paramount in this role. Candidates should demonstrate their commitment to safety and their knowledge of best practices.

- Emphasize your knowledge of safety protocols and regulations related to fiberglass handling.

- Provide examples of how you have maintained a safe and organized work environment.

- Discuss your understanding of the importance of personal protective equipment and its use.

4. Communication and Teamwork

Candidates should possess good communication skills and the ability to work effectively as part of a team.

- Highlight your experience in communicating with supervisors, colleagues, and customers.

- Discuss your ability to work collaboratively and contribute to team goals.

- Provide examples of how you have resolved conflicts and maintained a positive work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chopped Strand Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chopped Strand Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.