Are you gearing up for an interview for a Chopping Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chopping Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

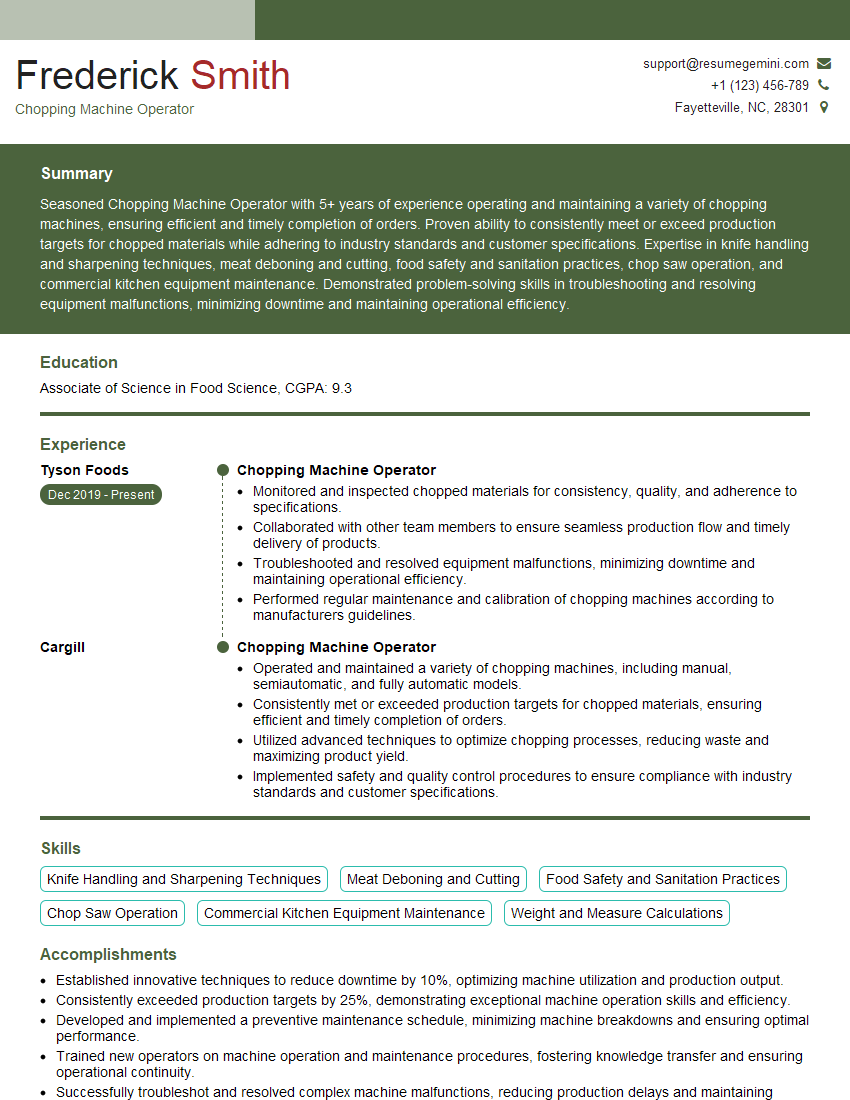

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chopping Machine Operator

1. Explain the process of operating a chopping machine?

In operating a chopping machine, there are several crucial steps to ensure efficient and safe functioning.

- Preparation: Gather necessary safety gear, inspect the machine for any damage, and prepare the ingredients for chopping.

- Positioning: Place the ingredients in the designated hopper or bowl of the machine according to the desired size and consistency.

- Adjustments: Set the blade speed, chopping time, and other parameters based on the type and quantity of ingredients being processed.

- Activation: Start the machine and monitor its operation to ensure proper chopping action.

- Monitoring: Keep a vigilant eye on the chopping process, ensuring that the ingredients are being chopped to the desired texture and consistency.

- Completion: Once the chopping is complete, turn off the machine and carefully remove the chopped ingredients.

- Cleanup: Thoroughly clean and sanitize the machine according to established protocols to maintain hygiene and prevent contamination.

2. What are the different types of chopping blades and their applications?

Blade Types:

- Straight Blades: General-purpose blades for chopping a variety of ingredients into uniform pieces.

- Serrated Blades: Ideal for chopping fibrous or tough ingredients, such as carrots or celery, to achieve a clean and precise cut.

- Julienne Blades: Designed to create long, thin strips of vegetables, suitable for salads or garnishes.

- Dicing Blades: Used to cut ingredients into uniform cubes, perfect for preparing ingredients for stews or casseroles.

Applications:

- Food Preparation: Chopping vegetables, fruits, herbs, and other ingredients for various dishes and cuisines.

- Industrial Processing: Bulk chopping of ingredients for food manufacturing, pharmaceutical production, and more.

- Laboratories: Preparing samples for scientific research and analysis.

3. How do you ensure the safety of yourself and others when operating a chopping machine?

- Proper Training: Receive comprehensive training on the operation and safety protocols of the chopping machine.

- Safety Gear: Always wear appropriate safety gear, including gloves, earplugs, and safety glasses.

- Machine Inspection: Regularly inspect the machine for any damage or malfunction before operation.

- Sharp Blades: Ensure that the blades are sharp and properly secured to prevent slipping or breakage.

- Careful Loading: Load ingredients carefully to avoid overloading or jamming the machine.

- Never Reach In: Never attempt to reach into the machine while it is running.

- Emergency Stop: Be familiar with the emergency stop button and use it immediately in case of any incident.

4. What are the common maintenance procedures for a chopping machine?

- Daily Cleaning: Clean the machine thoroughly after each use to prevent buildup and contamination.

- Blade Sharpening: Regularly sharpen the blades to maintain optimal cutting performance.

- Lubrication: Lubricate moving parts as per the manufacturer’s instructions to ensure smooth operation.

- Electrical Checks: Inspect electrical components regularly for any loose connections or damage.

- General Inspection: Conduct regular visual inspections to identify any signs of wear or damage.

5. How do you troubleshoot common problems with a chopping machine?

- Machine Not Starting: Check power supply, ensure the machine is properly plugged in, and inspect for any blown fuses.

- Uneven Chopping: Inspect the blades for sharpness, adjust blade speed or chopping time as needed.

- Overheating: Allow the machine to cool down, check for any blockages or overloading.

- Excessive Noise or Vibration: Inspect for loose parts, check blade alignment, and ensure proper lubrication.

- Leaking: Identify the source of the leak, tighten any loose parts, or replace damaged seals.

6. What is the difference between a chopping machine and a food processor?

- Purpose: Chopping machines are specifically designed for chopping ingredients, while food processors have multiple functions, including chopping, slicing, grating, and more.

- Blade Type: Chopping machines typically use fixed blades, while food processors often have interchangeable blades for various tasks.

- Capacity: Chopping machines generally have a smaller capacity compared to food processors.

- Speed and Power: Chopping machines are designed for high-speed chopping, while food processors may have variable speed settings.

7. What are the factors to consider when choosing the right chopping machine?

- Purpose and Usage: Determine the specific chopping tasks and frequency of use.

- Capacity: Consider the volume of ingredients that need to be chopped on a regular basis.

- Blade Type: Select the appropriate blade type based on the desired chopping texture and consistency.

- Speed and Power: Evaluate the required chopping speed and power to meet production needs.

- Safety Features: Ensure the machine has essential safety features, such as blade guards and emergency stop buttons.

- Maintenance: Consider the ease of cleaning, blade sharpening, and overall maintenance requirements.

8. Describe your experience with different types of chopping machines and their applications.

I have worked with various models of chopping machines, including manual, semi-automatic, and fully automatic. In the food processing industry, I operated a high-volume chopping machine to prepare large batches of vegetables for sauces, soups, and fillings.

In a laboratory setting, I used a precision chopping machine to prepare samples for chemical analysis. The machine’s ability to produce consistent and finely chopped samples was crucial for accurate results.

9. How do you handle situations when the chopping machine malfunctions during operation?

- Safety First: Immediately turn off the machine and disconnect the power source.

- Identify the Problem: Attempt to identify the cause of the malfunction based on any unusual noises, vibrations, or error messages.

- Troubleshooting: Refer to the user manual or consult with a qualified technician to troubleshoot the issue.

- Repair or Replacement: If the malfunction cannot be resolved, arrange for repairs or replacement of the machine to ensure safe and efficient operation.

- Documentation: Document the malfunction, troubleshooting steps, and any repairs or replacements for future reference.

10. What are your strengths and weaknesses as a Chopping Machine Operator?

Strengths:

- Exceptional attention to detail and precision in chopping ingredients.

- Proficient in operating and maintaining various types of chopping machines.

- Strong understanding of food safety and hygiene practices.

- Ability to work efficiently in a fast-paced and demanding environment.

- Excellent communication and teamwork skills.

Weaknesses:

- Limited experience with industrial-scale chopping machines.

- Need to improve knowledge of electrical troubleshooting techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chopping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chopping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chopping Machine Operators are responsible for operating and maintaining chopping machines used to cut and process various materials such as food, wood, or other products. Key job responsibilities include:1. Machine Operation

– Setting up and operating chopping machines according to established procedures. – Monitoring equipment during operation, ensuring smooth functioning. – Adjusting machine settings to achieve desired results. – Identifying and resolving any operational issues.2. Material Handling

– Loading and unloading raw materials into and out of the machine. – Inspecting materials for quality and correctness. – Maintaining a clean work area and adhering to safety protocols.3. Quality Control

– Inspecting the chopped materials for quality and size consistency. – Verifying product specifications and packaging requirements. – Reporting any quality deviations or issues to supervisors.4. Machine Maintenance

– Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs. – Recognizing major equipment breakdowns and notifying supervisors. – Collaborating with maintenance personnel for major repairs or overhauls.Interview Tips

To prepare for a Chopping Machine Operator interview, candidates should:1. Research the Company and Role

– Learn about the company’s industry, size, and products or services. – Read the job description carefully and identify the key responsibilities and qualifications.2. Practice Common Interview Questions

– Prepare answers to behavioral questions, such as “Tell me about a time you resolved a problem,” or “How do you handle working under pressure?” – Practice technical questions related to chopping machine operation and maintenance.3. Highlight Relevant Skills and Experience

– Emphasize experience in operating and maintaining chopping machines. – Showcase any knowledge of quality control processes and material handling. – Mention a background in a similar industrial setting or food production.4. Demonstrate Attention to Detail and Safety

– Explain your understanding of the importance of attention to detail in chopping operations. – Describe your knowledge of safety protocols and practices in an industrial environment.5. Prepare Questions for the Interviewer

– Ask thoughtful questions about the role, company, or industry to demonstrate your interest and engagement. – Inquiries about training opportunities or career growth paths can show your long-term commitment.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chopping Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!