Are you gearing up for a career in Chrome Plater? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chrome Plater and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

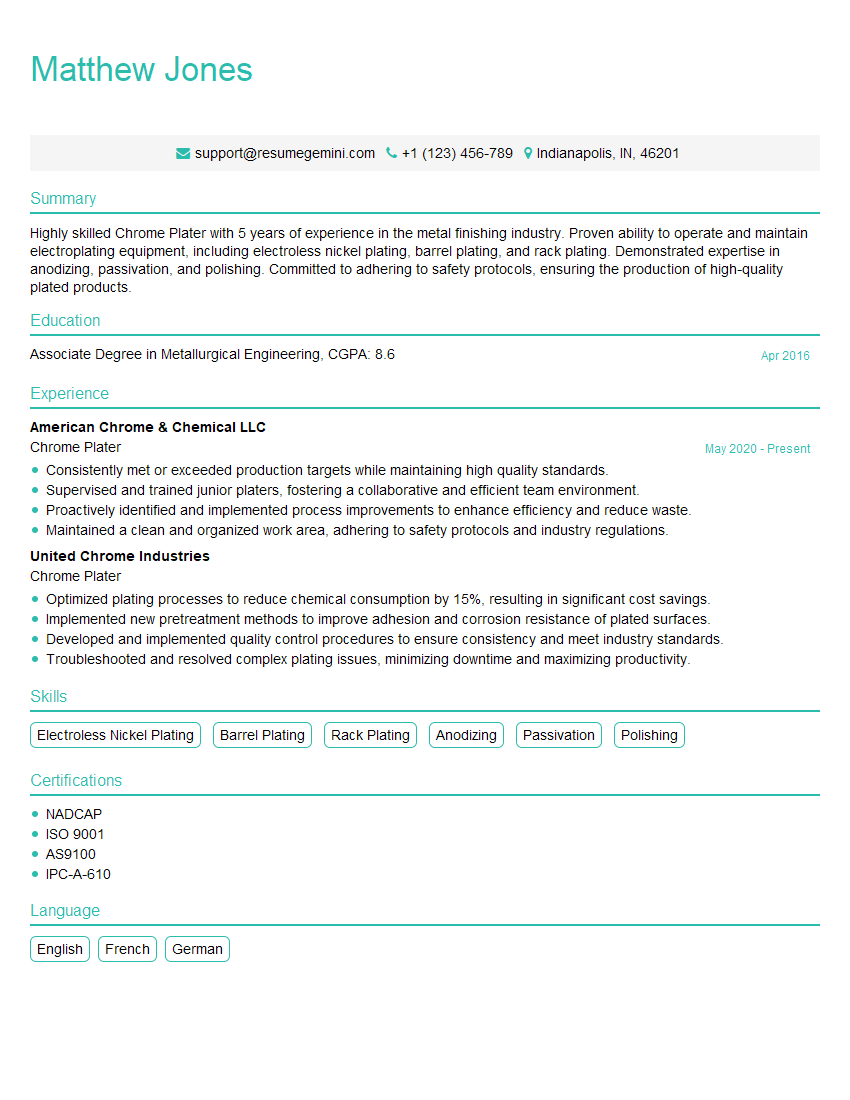

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chrome Plater

1. What is the difference between decorative chrome plating and hard chrome plating?

- Decorative chrome plating is used to improve the appearance of an object, while hard chrome plating is used to increase its durability and wear resistance.

- Decorative chrome plating is typically thinner than hard chrome plating.

- Decorative chrome plating is often used on items such as jewelry, while hard chrome plating is often used on items such as machine parts.

2. What are the different types of chrome plating baths?

Acid baths

- Acid baths are the most common type of chrome plating bath.

- They are typically used for decorative chrome plating.

- Acid baths contain chromic acid, sulfuric acid, and water.

Basic baths

- Basic baths are less common than acid baths.

- They are typically used for hard chrome plating.

- Basic baths contain chromic oxide, sodium hydroxide, and water.

3. What are the key factors that affect the quality of chrome plating?

- The type of chrome plating bath

- The concentration of the chemicals in the bath

- The temperature of the bath

- The duration of the plating process

- The surface preparation of the object being plated

4. What are the common problems that can occur during chrome plating?

- Blistering

- Peeling

- Cracking

- Pitting

- Discoloration

5. How can these problems be prevented?

- Blistering can be prevented by ensuring that the object being plated is properly cleaned and degreased.

- Peeling can be prevented by ensuring that the object being plated is properly etched.

- Cracking can be prevented by ensuring that the object being plated is plated at the correct temperature.

- Pitting can be prevented by ensuring that the object being plated is plated in a clean bath.

- Discoloration can be prevented by ensuring that the object being plated is rinsed thoroughly after plating.

6. What are the safety precautions that must be taken when working with chrome plating chemicals?

- Chrome plating chemicals are corrosive and can cause skin burns.

- They should be handled with care and in a well-ventilated area.

- Personal protective equipment, such as gloves, goggles, and a respirator, should be worn when working with chrome plating chemicals.

7. What is the role of the chromate conversion coating in chrome plating?

- The chromate conversion coating is a thin layer of chromium oxide that is applied to the chrome plated surface.

- It helps to protect the chrome plated surface from corrosion and wear.

- It also improves the adhesion of paint and other coatings to the chrome plated surface.

8. What are the different methods of applying a chromate conversion coating?

- Dip coating

- Spray coating

- Brush coating

9. What are the key factors that affect the quality of a chromate conversion coating?

- The type of chromate conversion coating

- The concentration of the chemicals in the solution

- The temperature of the solution

- The duration of the coating process

- The surface preparation of the object being coated

10. What are the common problems that can occur during the application of a chromate conversion coating?

- Blistering

- Peeling

- Cracking

- Discoloration

11. How can these problems be prevented?

- Blistering can be prevented by ensuring that the object being coated is properly cleaned and degreased.

- Peeling can be prevented by ensuring that the object being coated is properly etched.

- Cracking can be prevented by ensuring that the object being coated is coated at the correct temperature.

- Discoloration can be prevented by ensuring that the object being coated is rinsed thoroughly after coating.

12. What are the safety precautions that must be taken when working with chromate conversion coating chemicals?

- Chromate conversion coating chemicals are corrosive and can cause skin burns.

- They should be handled with care and in a well-ventilated area.

- Personal protective equipment, such as gloves, goggles, and a respirator, should be worn when working with chromate conversion coating chemicals.

13. What are the different types of equipment used in chrome plating?

- Plating tanks

- Rectifiers

- Anodes

- Cathodes

- Filters

14. What are the key factors to consider when selecting a chrome plating tank?

- The size of the tank

- The type of material the tank is made from

- The capacity of the tank

- The cost of the tank

15. What are the different types of rectifiers used in chrome plating?

- Single-phase rectifiers

- Three-phase rectifiers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chrome Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chrome Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chrome Platers are responsible for applying a thin layer of chromium to metal surfaces to improve their corrosion resistance, wear resistance, and appearance. Their key job responsibilities include:

1. Preparation of Metal Surfaces

Preparing metal surfaces for chrome plating involves cleaning, degreasing, and polishing the surfaces to ensure proper adhesion of the chromium coating.

- Cleaning metal surfaces using solvents, detergents, or alkaline solutions to remove dirt, oil, and other contaminants.

- Degreasing metal surfaces using organic solvents or chemical solutions to remove any remaining oils or greases that could interfere with the plating process.

- Polishing metal surfaces using abrasive materials or mechanical polishing tools to smooth and level the surfaces, creating a better surface for the chromium coating to adhere to.

2. Electroplating Process

Electroplating is the process of using an electric current to reduce dissolved metal ions in a solution onto a metal surface. In chrome plating, chromium ions are reduced and deposited onto the prepared metal surface.

- Suspending the prepared metal parts in a plating solution containing chromium ions.

- Connecting the metal parts to the negative terminal of a power supply (cathode) and the chromium anode to the positive terminal (anode).

- Passing an electric current through the solution, causing chromium ions to migrate towards the cathode and deposit onto the metal parts.

3. Post-Plating Treatments

After electroplating, the plated metal parts may undergo additional treatments to enhance their properties or appearance.

- Heat treating the plated parts to improve their hardness and wear resistance.

- Polishing the plated parts to achieve a desired surface finish and luster.

- Applying protective coatings to the plated parts to prevent tarnishing or corrosion.

4. Quality Control

Chrome Platers are responsible for ensuring the quality of the plated parts. This involves inspecting the parts for defects, measuring the thickness of the chromium coating, and testing the parts for corrosion resistance and other properties.

- Visually inspecting the plated parts for any defects such as pitting, surface roughness, or discoloration.

- Using thickness gauges or other measuring equipment to measure the thickness of the chromium coating.

- Conducting corrosion resistance tests by exposing the plated parts to corrosive environments and monitoring their performance.

Interview Tips

Preparing for an interview can help you make a positive impression and increase your chances of getting the job. Here are some tips to help you prepare for a Chrome Plater interview:

1. Research the Company

Learn about the company’s history, products, services, and culture. This will help you understand the company’s needs and how your skills and experience can benefit them.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to people who work or have worked for the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise way.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Highlight your skills and experience that are relevant to the job.

- Be prepared to talk about your strengths and weaknesses.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the job.

- Ask about the company’s plans for growth.

- Ask about the challenges and opportunities facing the company.

- Ask about the company’s culture and values.

4. Dress Professionally

First impressions matter. Dress appropriately for the interview, which typically means business casual attire. Make sure your clothes are clean, pressed, and fit well.

- Wear a suit or dress pants and a button-down shirt.

- Choose closed-toe shoes.

- Avoid wearing excessive jewelry or perfume.

5. Be Confident and Enthusiastic

Confidence and enthusiasm can go a long way in an interview. Believe in yourself and your abilities. Show the interviewer that you are excited about the opportunity to work for the company.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chrome Plater, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chrome Plater positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.