Feeling lost in a sea of interview questions? Landed that dream interview for Chronometer Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chronometer Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

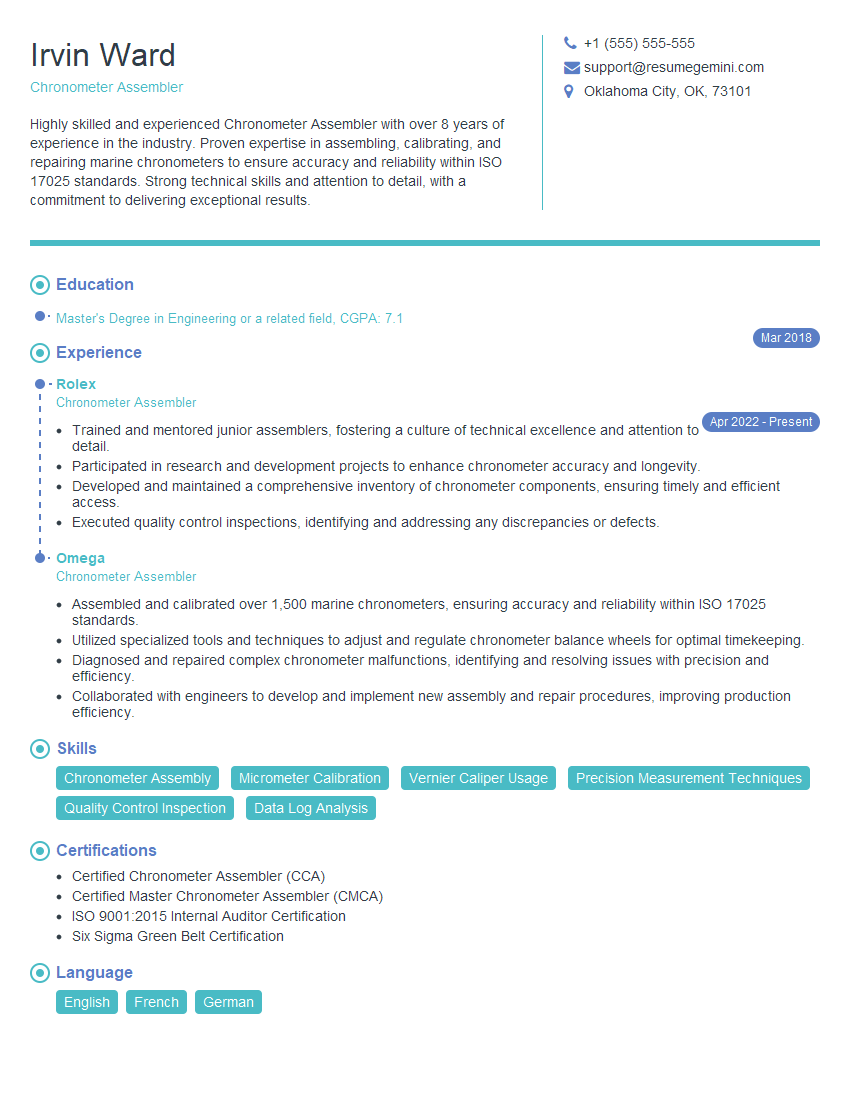

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chronometer Assembler

1. Explain the key components of a chronometer and their functions?

- Balance Wheel: Regulates the timekeeping accuracy by oscillating at a constant frequency.

- Hairspring: Provides the restoring force for the balance wheel and controls its oscillation rate.

- Escapement: Connects the balance wheel to the gear train, releasing energy from the mainspring to power the movement.

- Mainspring: Stores energy and provides the power to drive the gear train and escapement.

- Gear Train: Transmits power from the mainspring to the hands, indicating the time.

2. Describe the different types of chronometer movements and their advantages and disadvantages?

Mechanical Movement

- Advantages: Precise, durable, collectible value.

- Disadvantages: Requires regular servicing, can be affected by temperature and shock.

Quartz Movement

- Advantages: Highly accurate, low maintenance, affordable.

- Disadvantages: Less durable, limited collectible value.

Atomic Movement

- Advantages: Extremely accurate, not affected by temperature or shock.

- Disadvantages: Expensive, not widely used in wristwatches.

3. What tools and equipment are essential for a chronometer assembler?

- Magnification devices (loupe, microscope)

- Tweezers and forceps

- Screwdrivers

- Oiler and cleaning solutions

- Assembly trays and parts containers

4. How do you ensure the precision and accuracy of a chronometer during assembly?

- Follow technical specifications and assembly procedures meticulously.

- Use calibrated and high-quality tools and equipment.

- Inspect components for defects and clean them thoroughly before assembly.

- Lubricate moving parts appropriately to reduce friction and wear.

- Calibrate and test the chronometer after assembly to meet accuracy standards.

5. What are the potential challenges in assembling a chronometer and how do you overcome them?

- Tiny and delicate components: Requires steady hands, fine motor skills, and extreme precision.

- High accuracy requirements: Demands meticulous attention to detail and adherence to specifications.

- Environmental factors: Temperature, humidity, and dust can impact accuracy, so controlled assembly conditions are crucial.

6. Describe the quality control procedures involved in chronometer assembly?

- Visual inspection of components and assembly

- Mechanical testing (e.g., timekeeping accuracy, power reserve)

- Compliance checks against technical specifications

- Certification testing (e.g., COSC standards)

7. How do you stay up-to-date with the latest advancements in chronometer assembly techniques?

- Attending industry workshops and conferences

- Reading technical publications and online resources

- Networking with other chronometer assemblers and experts

- Participating in research and development projects

8. What is your understanding of the role of a chronometer in modern navigation and timekeeping?

- High-precision timekeeping for scientific research

- Navigation in aviation, marine, and space applications

- Precise synchronization in communication and networking systems

- Accurate timing in professional sports and competitions

9. What are your strengths and weaknesses as a chronometer assembler?

- Strengths: Steady hands, fine motor skills, meticulous attention to detail, problem-solving abilities.

- Weaknesses: I am still relatively new to the industry and lack some experience with specific high-end chronometer models.

10. Why are you interested in working as a Chronometer Assembler?

- Passion for precision mechanics and timekeeping

- Interest in the historical and technical significance of chronometers

- Desire to contribute to the creation of highly accurate and reliable instruments

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chronometer Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chronometer Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chronometer Assembler plays a vital role in the production and maintenance of chronometers, devices that measure time with high precision. Their responsibilities encompass various aspects of chronometer assembly, ensuring accuracy and functionality.

1. Chronometer Assembly

The primary task of a Chronometer Assembler is to assemble chronometers according to technical specifications and blueprints. This involves:

- Selecting and fitting components, such as gears, springs, and balance wheels

- Adjusting and calibrating components to ensure precise timekeeping

2. Quality Control and Testing

To guarantee the accuracy of chronometers, Assemblers perform rigorous quality control checks. They:

- Inspect components for defects and verify their dimensions

- Conduct performance tests to assess timing accuracy and reliability

3. Maintenance and Repair

Chronometer Assemblers are also responsible for maintaining and repairing existing chronometers. This includes:

- Diagnosing and troubleshooting malfunctions

- Replacing or repairing damaged components

- Performing regular maintenance to ensure optimal performance

4. Documentation and Record-Keeping

Assemblers maintain detailed records of assembly and maintenance procedures. They also:

- Document quality control results and testing data

- Generate reports on chronometer performance and repairs

Interview Tips

Preparing thoroughly for a Chronometer Assembler interview can greatly enhance your chances of success. Here are some tips to help you ace it:

1. Research the Company and Position

Thoroughly research the company’s history, products, and reputation. Understand the specific requirements of the Assembler position and its alignment with your skills and experience.

2. Practice Answering Common Interview Questions

Anticipate and prepare your responses to common interview questions. Consider questions about your technical expertise, problem-solving abilities, and experience in chronometer assembly and maintenance.

3. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize your relevant skills and experience. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

4. Prepare Technical Questions

Asking well-informed technical questions during the interview shows your interest and understanding of the field. Consider asking about the company’s chronometer production process, calibration techniques, or quality control standards.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Your attire and demeanor convey respect for the company and the position.

6. Be Confident and Communicate Clearly

Project confidence and communicate your ideas clearly during the interview. Listen attentively to the interviewer’s questions and respond thoughtfully, providing specific examples and technical details where appropriate.

7. Follow Up

After the interview, send a thank-you note to the interviewer. reiterate your interest in the position and highlight any additional information or qualifications that may have been overlooked during the interview.

Next Step:

Now that you’re armed with the knowledge of Chronometer Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Chronometer Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini