Feeling lost in a sea of interview questions? Landed that dream interview for Chucking and Sawing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chucking and Sawing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

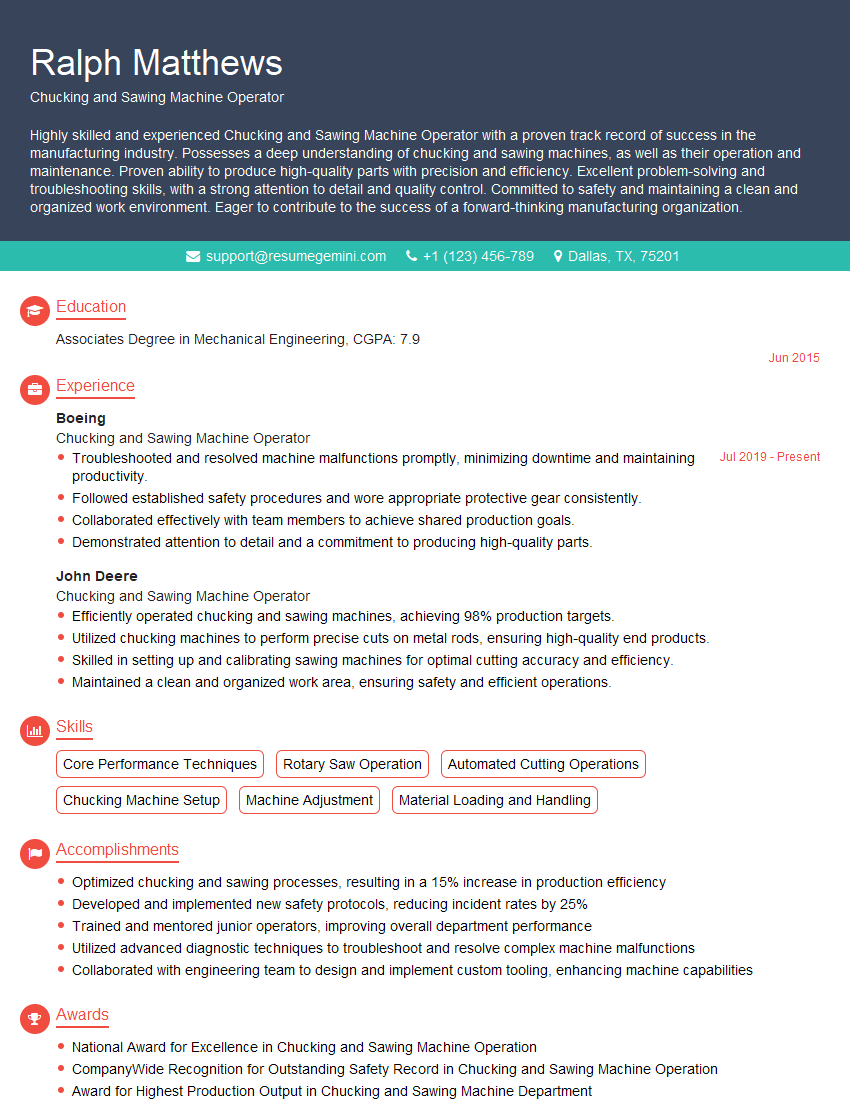

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chucking and Sawing Machine Operator

1. Please describe the key tasks and responsibilities involved in your previous role as a chucking and sawing machine operator?

In my previous role, I was responsible for a wide range of tasks, including:

- Operating chucking and sawing machines to cut, shape, and finish metal parts according to specifications

- Setting up and adjusting machines, selecting and installing cutting tools, and ensuring proper machine alignment

- Measuring and inspecting parts to ensure they meet the required dimensions and tolerances

- Maintaining a clean and organized work area and following established safety protocols

2. How would you troubleshoot a chucking or sawing machine that is not functioning properly?

Diagnosis:

- Identify the symptoms of the malfunction, such as unusual noises, vibrations, or error messages

- Check the machine’s power supply and connections to ensure they are secure

- Inspect the cutting tools for damage or wear and replace them if necessary

Repair:

- If the problem is caused by a mechanical issue, such as a faulty bearing or gear, it will need to be repaired or replaced

- If the problem is caused by a software glitch, it may be possible to reset the machine or update its firmware

3. What are the safety precautions that you must observe when working with chucking and sawing machines?

The following safety precautions are essential when working with chucking and sawing machines:

- Always wear appropriate safety gear, such as safety glasses, earplugs, and gloves

- Keep the work area clean and free of debris to prevent slips and falls

- Never operate the machine with loose clothing or long hair that could get caught in the machinery

- Be aware of the location of all emergency stop buttons and know how to use them

4. Describe the different types of cutting tools used in chucking and sawing operations and explain how to select the appropriate tool for a specific task?

There are various types of cutting tools used in chucking and sawing operations, each with its own specific purpose and application:

- Chucking tools hold the workpiece securely in place while it is being machined

- Sawing tools, such as circular saws and band saws, are used to cut through metal

- The appropriate tool for a specific task depends on the type of metal being cut, the desired cut quality, and the required production rate

5. Explain the importance of coolant in chucking and sawing operations and describe the different types of coolant that can be used?

Coolant plays a crucial role in chucking and sawing operations, providing the following benefits:

- Lubrication: Reduces friction between the cutting tool and the workpiece, extending tool life

- Cooling: Removes heat generated during cutting, preventing the workpiece and cutting tool from overheating

- Chip removal: Flushes away metal chips from the cutting zone, improving surface finish

Different types of coolant can be used, including:

- Water-based coolants: Most common, provide good cooling and lubrication

- Oil-based coolants: Offer superior lubrication but may require specialized disposal methods

- Synthetic coolants: Long-lasting and provide a balance of cooling and lubrication

6. How do you maintain and calibrate a chucking and sawing machine to ensure accurate and efficient operation?

Maintenance:

- Regularly clean and lubricate all machine components

- Inspect and replace worn or damaged parts

- Follow manufacturer’s recommended maintenance schedule

Calibration:

- Use precision measuring tools to ensure accuracy of machine settings

- Calibrate the machine according to manufacturer’s specifications

- Regularly verify calibration to maintain optimal performance

7. Explain the concept of kerf width and how it affects the overall cutting process?

Kerf width refers to the width of the cut made by a sawing machine. It is determined by the thickness of the saw blade and the angle at which it is set.

- Narrow kerf widths result in less material waste but may require more power and generate more heat

- Wider kerf widths produce less heat and require less power but result in more material waste

The kerf width must be considered when selecting a saw blade for a specific application.

8. How would you optimize the cutting parameters, such as feed rate and spindle speed, to achieve maximum efficiency and productivity?

Optimizing cutting parameters involves balancing factors such as:

- Feed rate: The rate at which the workpiece is fed into the cutting tool

- Spindle speed: The speed at which the cutting tool rotates

- Material properties: Hardness, thickness, and machinability of the workpiece

- Cutting tool: Type, geometry, and sharpness of the cutting tool

The goal is to find the combination of parameters that produces the desired cut quality, minimizes cycle time, and extends tool life.

9. What are the different types of materials that can be cut using a chucking and sawing machine, and how do their properties affect the cutting process?

Chucking and sawing machines can cut a variety of materials, including:

- Metals: Steel, aluminum, brass, copper, and titanium

- Plastics: Acrylic, polycarbonate, and PVC

- Wood: Hardwoods, softwoods, and plywood

The properties of the material, such as hardness, toughness, and grain structure, influence the cutting parameters and tool selection.

10. Describe your experience in programming and operating CNC (computer numerical control) chucking and sawing machines?

In my previous role, I was responsible for programming and operating CNC chucking and sawing machines. I have experience with various CNC systems and programming languages, including:

- G-code: A widely used programming language for CNC machines

- CAM software: Computer-aided manufacturing software used to create CNC programs

I have successfully programmed and operated CNC machines to produce complex parts with high accuracy and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chucking and Sawing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chucking and Sawing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chucking and Sawing Machine Operators are responsible for operating sawing machines to cut materials such as metal, wood, or plastic into specific shapes and sizes. They ensure that the machine is operating safely and efficiently, and that the finished products meet quality standards.

1. Operating Sawing Machines

Chucking and Sawing Machine Operators must be able to operate a variety of sawing machines, including circular saws, band saws, and jigsaws. They must understand the different types of blades and materials, and how to adjust the machine settings to produce the desired results.

2. Material Handling

Chucking and Sawing Machine Operators must be able to safely handle heavy materials. They must be able to load and unload materials, and to move them around the work area. They must also be able to identify and avoid potential hazards, such as sharp edges or moving machinery.

3. Quality Control

Chucking and Sawing Machine Operators are responsible for ensuring that the finished products meet quality standards. They must be able to inspect products for defects, and to make adjustments to the machine as needed to correct errors.

4. Machine Maintenance

Chucking and Sawing Machine Operators are responsible for performing basic maintenance on their machines. They must be able to clean and lubricate the machine, and to change blades and other components.

Interview Tips

Preparing for an interview for a Chucking and Sawing Machine Operator position can be daunting, but with the right strategies, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Take the time to research the company you are interviewing with. Learn about their history, their products or services, and their company culture. This will show the interviewer that you are interested in the position and that you have taken the time to learn more about the company.

2. Practice Your Answers

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” This will help you to feel more confident and prepared during the interview.

3. Be Enthusiastic

Let the interviewer know that you are enthusiastic about the position and that you are eager to learn more about the company. Your enthusiasm will be contagious and will make the interviewer more likely to want to hire you.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chucking and Sawing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chucking and Sawing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.