Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chucking Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

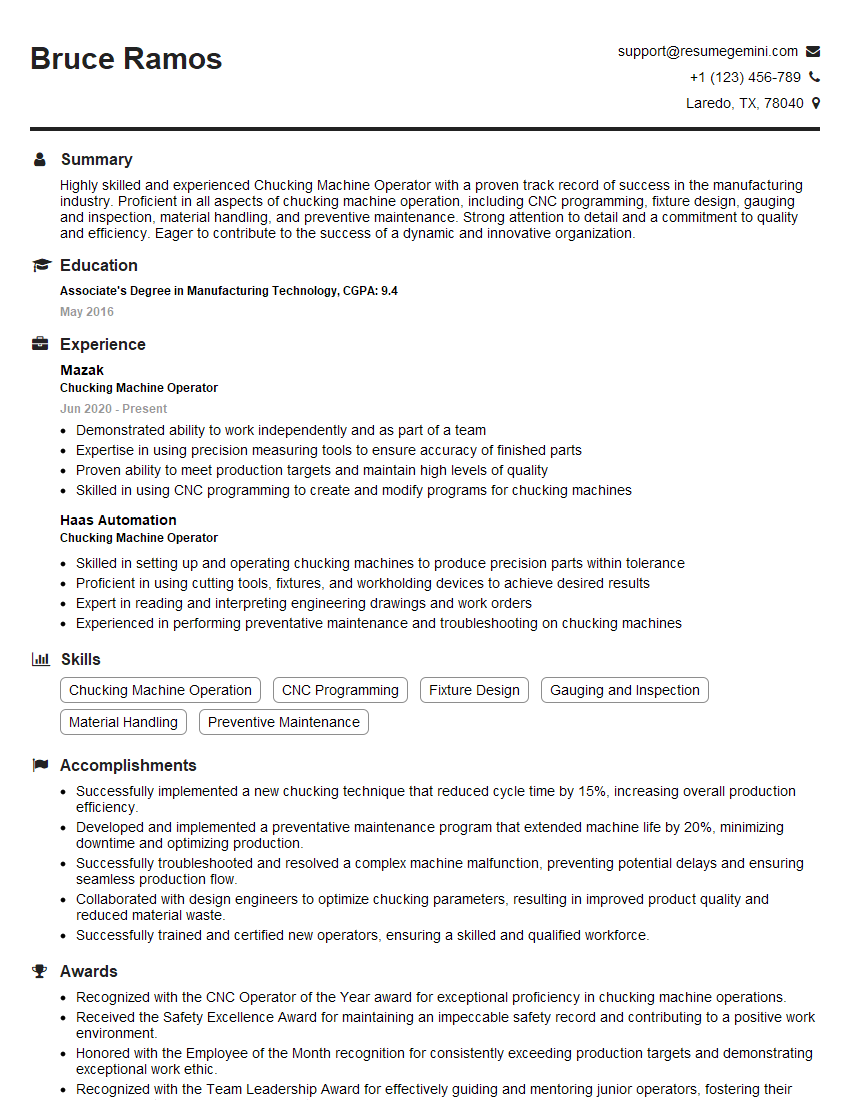

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chucking Machine Operator

1. Describe your experience with different chucking machine types?

In my previous role as a Chucking Machine Operator, I have extensive experience working with various chucking machine types, including:

- Single-spindle chucking machines

- Multi-spindle chucking machines

- CNC chucking machines

- Bar chucking machines

2. Explain the process of setting up and operating a chucking machine?

Chucking Machine Setup:

- Mount and align the chuck on the machine spindle.

- Install the workpiece into the chuck and secure it.

- Set the machine parameters, including speed, feed, and depth of cut.

- Load the CNC program or manually input the machining sequence.

Chucking Machine Operation:

- Initiate the machining cycle and monitor its progress.

- Make adjustments to the machine parameters as needed.

- Inspect the finished workpiece for accuracy and quality.

3. What types of materials have you worked with on a chucking machine?

I have experience working with a wide range of materials on a chucking machine, including:

- Metals: Steel, aluminum, brass, copper

- Plastics: ABS, polycarbonate, nylon

- Wood

4. Explain the importance of proper chucking techniques and how they affect workpiece accuracy?

Proper chucking techniques are crucial for ensuring workpiece accuracy and minimizing vibration during machining. By securely holding the workpiece in the chuck, I can:

- Prevent workpiece slippage and reduce the risk of inaccurate cuts.

- Minimize chatter and improve surface finish.

- Maintain consistent dimensions and tolerances throughout the machining process.

- Extend the life of cutting tools.

5. How do you handle and troubleshoot common chucking machine problems?

I have encountered and resolved various common chucking machine problems during my experience, including:

- Chuck slippage: Adjust chuck pressure or use a different chucking method.

- Vibration: Check for proper workpiece balance, adjust machine speeds and feeds, or use vibration dampeners.

- Tool breakage: Inspect cutting tools for wear, adjust machine parameters, or use a different cutting strategy.

- Surface finish issues: Check for proper tool selection, cutting parameters, and workpiece material compatibility.

6. Describe your knowledge of CNC programming for chucking machines and how you use it to optimize machining processes?

I am proficient in CNC programming for chucking machines. I use CNC programs to:

- Automate machining sequences and reduce production time.

- Optimize tool path and cutting parameters for efficiency.

- Create complex machining geometries with precision and accuracy.

- Monitor and adjust machine parameters during machining for optimal performance.

7. How do you ensure safety when operating chucking machines?

Safety is paramount in my chucking machine operation practices. I adhere to the following safety measures:

- Wear appropriate personal protective equipment (PPE).

- Inspect the machine and tooling before each operation.

- Securely mount and guard the workpiece and cutting tools.

- Follow established safety protocols and lockout procedures.

- Remain alert and aware of potential hazards during machining.

8. What techniques do you use to measure and inspect the accuracy and quality of machined workpieces?

I use a combination of techniques to ensure the accuracy and quality of machined workpieces, including:

- Precision measuring tools (calipers, micrometers, gauges)

- Inspection techniques (visual inspection, CMM scanning)

- Quality control procedures and documentation

- Statistical process control (SPC) methods

9. Describe your experience with maintenance and troubleshooting of chucking machines?

I have a good understanding of chucking machine maintenance and troubleshooting. I am responsible for:

- Regular maintenance tasks (lubrication, cleaning, adjustments)

- Troubleshooting common machine issues and resolving them effectively

- Collaborating with maintenance technicians for major repairs or upgrades

- Keeping maintenance records and following preventive maintenance schedules

10. How do you stay updated with the latest advancements in chucking machine technology and best practices?

I am committed to continuous learning and staying informed about the latest advancements in chucking machine technology and best practices. I attend industry events and workshops, read trade publications, and engage in online forums and discussions. This allows me to:

- Enhance my knowledge and skills in chucking machine operation.

- Identify and implement new technologies and techniques to improve efficiency.

- Meet industry standards and regulations.

- Contribute to the advancement of chucking machine technology and practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chucking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chucking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chucking Machine Operators are responsible for operating and maintaining chucking machines, which are used to manufacture precision metal parts. They must have a strong understanding of the machine’s operation and maintenance procedures, as well as the ability to read and interpret blueprints and other technical drawings.

1. Operate chucking machines

This involves loading and unloading workpieces, setting up the machine, and operating it according to the specified instructions.

- Loading and unloading workpieces

- Setting up the machine

- Operating the machine according to the specified instructions

2. Monitor the machine’s operation

This involves watching the machine for any signs of trouble, such as excessive vibration or noise, and taking corrective action if necessary.

- Watching the machine for any signs of trouble

- Taking corrective action if necessary

3. Maintain the machine

This involves cleaning and lubricating the machine, as well as performing minor repairs.

- Cleaning and lubricating the machine

- Performing minor repairs

4. Inspect finished parts

This involves checking the parts for defects, such as cracks or burrs, and measuring them to ensure that they meet the specified tolerances.

- Checking the parts for defects

- Measuring them to ensure that they meet the specified tolerances

Interview Tips

To ace an interview for a Chucking Machine Operator position, you should prepare yourself by practicing your answers to common interview questions and researching the company and the position. Here are some tips:

1. Practice answering common interview questions

The following are some of the most common interview questions that you may be asked:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with chucking machines?

- How do you maintain a chucking machine?

- How do you inspect finished parts?

- What is your availability?

- What is your salary expectation?

2. Research the company and the position

This will help you to answer questions about the company and the position, and it will also show the interviewer that you are interested in the company and the position.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully to understand the responsibilities of the position.

- Talk to your recruiter or other people in your network who work for the company.

3. Dress professionally and arrive on time for your interview

This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in business casual attire.

- Arrive on time for your interview.

4. Be yourself and be confident

The interviewer wants to get to know the real you, so be yourself and don’t try to be someone you’re not. Be confident in your abilities and your experience, and don’t be afraid to ask questions.

- Be yourself.

- Be confident in your abilities and your experience.

- Don’t be afraid to ask questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Chucking Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.