Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chute Feeder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

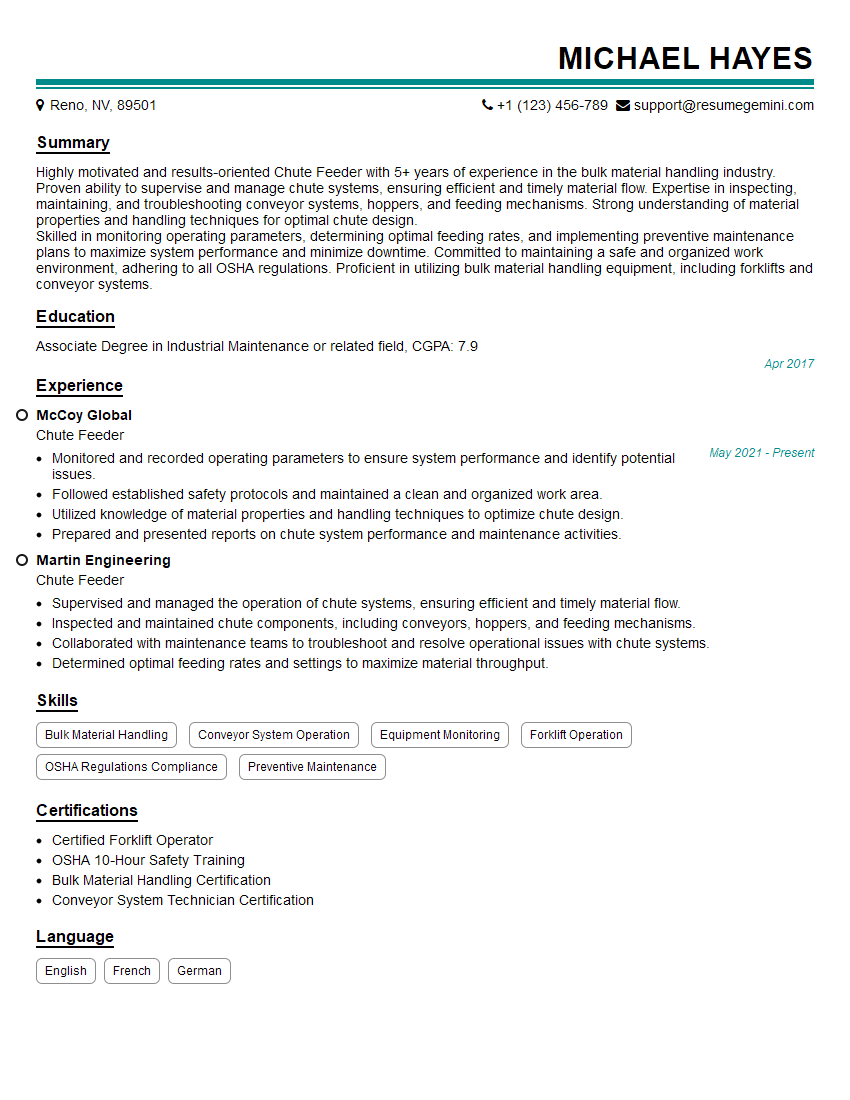

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chute Feeder

1. What are the different types of chute feeders and their applications?

- Vibrating Chute Feeders: These feeders use a vibrating motion to convey materials along a trough. They are suitable for feeding materials that are difficult to flow, such as powders, granules, and small parts.

- Screw Conveyors: Screw conveyors use a rotating screw to move materials along a trough. They are suitable for conveying a wide variety of materials, including solids, liquids, and powders.

- Belt Conveyors: Belt conveyors use a continuous belt to move materials along a flat surface. They are ideal for conveying large volumes of materials over long distances.

- Chain Conveyors: Chain conveyors use a chain to move materials along a track. They are suitable for conveying heavy materials or materials that are not easily conveyed on other types of feeders.

2. How do you size a chute feeder?

- Determine the material properties, including material density, particle size, and flowability.

- Calculate the required capacity of the feeder.

- Select a feeder type based on the material properties and capacity.

- Determine the dimensions of the feeder, including the length, width, and height.

- Specify the material of construction for the feeder.

3. What are the different materials used in the construction of chute feeders?

- Stainless Steel: Stainless steel is a durable and corrosion-resistant material that is ideal for use in food processing, pharmaceutical, and chemical processing applications.

- Mild Steel: Mild steel is a cost-effective material that is suitable for most industrial applications.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is ideal for use in aerospace and marine applications.

- Plastic: Plastic is a lightweight and low-cost material that is suitable for use in light-duty applications.

4. What are the different drive options for chute feeders?

- Electric Motors: Electric motors are the most common type of drive for chute feeders. They are reliable, efficient, and easy to control.

- Hydraulic Motors: Hydraulic motors are suitable for use in applications where high torque is required.

- Pneumatic Motors: Pneumatic motors are suitable for use in applications where a clean and oil-free environment is required.

5. What are the different control options for chute feeders?

- Manual Control: Manual control allows the operator to start and stop the feeder using a switch or button.

- Automatic Control: Automatic control allows the feeder to be started and stopped automatically based on a set of predetermined conditions.

- Programmable Logic Controllers (PLCs): PLCs are used to control the operation of chute feeders and other industrial equipment.

6. What are the different safety features that can be incorporated into chute feeders?

- Guarding: Guards can be installed around the feeder to prevent personnel from coming into contact with moving parts.

- Interlocks: Interlocks can be used to prevent the feeder from operating if a guard is not in place.

- Emergency Stop Buttons: Emergency stop buttons can be used to stop the feeder in the event of an emergency.

7. What are the different maintenance requirements for chute feeders?

- Regular Inspection: Chute feeders should be inspected regularly to identify any potential problems.

- Lubrication: Bearings and other moving parts should be lubricated regularly.

- Replacement of Worn Parts: Worn parts should be replaced as needed.

8. What are the troubleshooting tips for chute feeders?

- Check the power supply.

- Check the drive motor.

- Check the conveyor belt.

- Check the material flow.

9. What are the advantages of using chute feeders?

- Increased productivity.

- Reduced labor costs.

- Improved safety.

- Reduced waste.

10. What are the disadvantages of using chute feeders?

- High initial cost.

- Maintenance costs.

- Space requirements.

- Noise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chute Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chute Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chute Feeders are responsible for overseeing the operation of chute feeding machines in a manufacturing or production environment. They ensure that materials are fed into the machines correctly and efficiently, and that the machines are running smoothly.

1. Machine Operation and Monitoring

Chute Feeders are responsible for the safe and efficient operation of chute feeding machines.

- Set up and operate chute feeding machines according to established procedures.

- Monitor the machines’ performance, including speed, feed rate, and material flow.

2. Material Handling

Chute Feeders are responsible for handling the materials that are being fed into the machines.

- Load materials into the machines’ hoppers or chutes.

- Ensure that the materials are fed into the machines correctly and efficiently.

3. Machine Maintenance

Chute Feeders are responsible for performing basic maintenance on the machines.

- Clean and lubricate the machines.

- Inspect the machines for wear and tear, and report any problems to the supervisor.

4. Quality Control

Chute Feeders are responsible for ensuring that the materials that are being fed into the machines meet quality standards.

- Inspect materials for defects or contamination.

- Reject materials that do not meet quality standards.

Interview Tips

To ace the interview, candidates should be well-prepared. Here are a few tips:

1. Research the Company and Position

Before the interview, candidates should research the company and the position they are applying for. This will help them understand the company’s culture and values, and the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice Your Answers

Candidates should practice their answers to common interview questions. This will help them feel more confident and prepared during the interview.

- List out common interview questions.

- Craft a few sample answers for each question.

- Practice answering the questions out loud.

3. Dress Professionally

Candidates should dress professionally for the interview. This will show the interviewer that they are taking the interview seriously.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Groom yourself neatly.

4. Be Enthusiastic and Positive

Candidates should be enthusiastic and positive during the interview. This will make a good impression on the interviewer.

- Smile and make eye contact with the interviewer.

- Be upbeat and positive in your answers.

- Show your enthusiasm for the job and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chute Feeder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chute Feeder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.