Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chute Greaser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

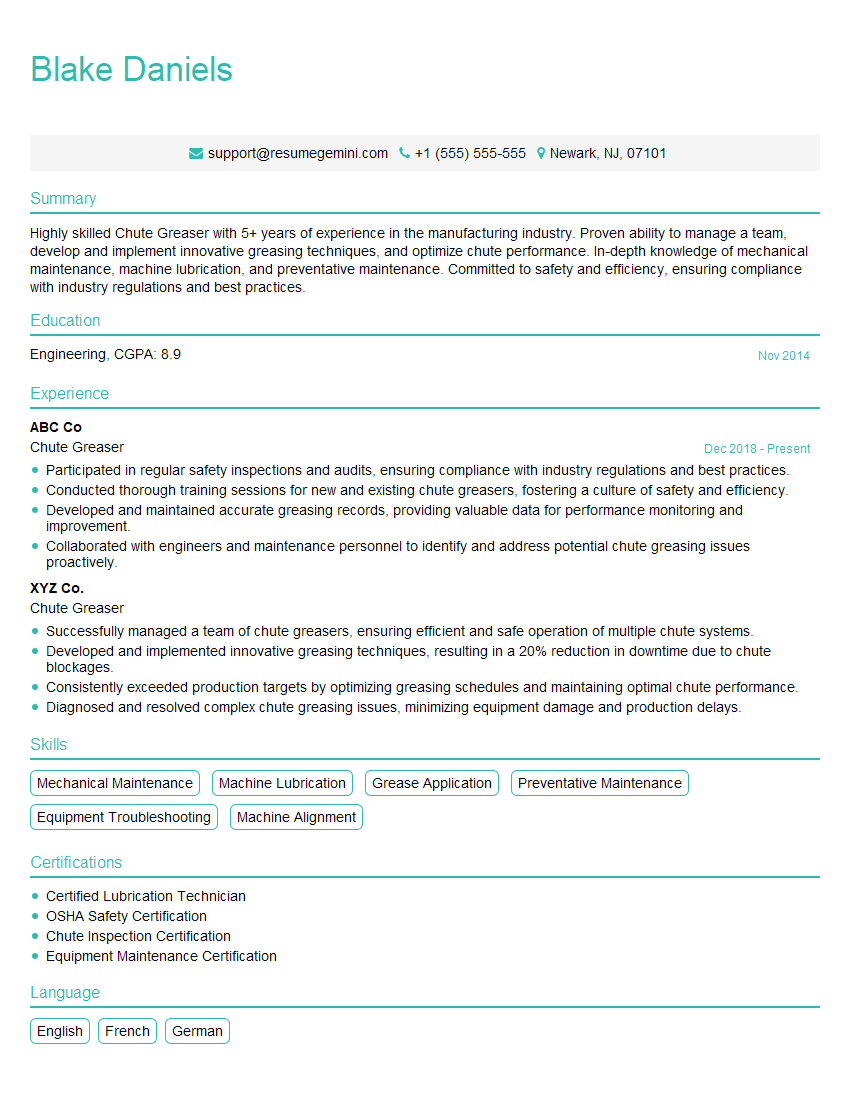

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chute Greaser

1. What are the key responsibilities of a Chute Greaser?

The key responsibilities of a Chute Greaser include:

- Applying grease to chutes and conveyors to minimize friction and wear.

- Inspecting chutes and conveyors for damage and wear, and reporting any issues to the supervisor.

- Cleaning and maintaining chutes and conveyors to ensure proper operation.

- Assisting with other maintenance tasks as assigned.

2. What types of greases are commonly used for chutes and conveyors?

Petroleum-based greases

- Advantages: Good water resistance, high load-carrying capacity, low cost.

- Disadvantages: Can attract dirt and debris, can be difficult to apply in cold weather.

Synthetic greases

- Advantages: Excellent water resistance, high temperature stability, long service life.

- Disadvantages: More expensive than petroleum-based greases.

Biodegradable greases

- Advantages: Environmentally friendly, can be used in food processing applications.

- Disadvantages: More expensive than petroleum-based greases, may not have the same performance characteristics.

3. What are the different methods of applying grease to chutes and conveyors?

- Manual application: Using a brush or grease gun to apply grease to the desired areas.

- Automated application: Using a centralized lubrication system to automatically apply grease to the desired areas.

4. What are the safety precautions that should be taken when applying grease to chutes and conveyors?

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Ensure that the chute or conveyor is properly shut down and locked out before applying grease.

- Avoid contact with hot or moving parts.

- Use proper lifting techniques when handling heavy grease containers.

- Dispose of used grease and rags properly.

5. What are the common maintenance tasks that a Chute Greaser may perform?

- Replacing worn or damaged chute liners.

- Repairing conveyor belts and rollers.

- Adjusting conveyor tension.

- Lubricating bearings and other moving parts.

6. What are the troubleshooting tips for a Chute Greaser?

- If grease is not being applied properly, check the grease lines for clogs or leaks.

- If a chute or conveyor is making noise, check for worn or damaged parts.

- If a chute or conveyor is not moving smoothly, check for obstructions or lubrication issues.

7. What are the key performance indicators (KPIs) for a Chute Greaser?

- Number of chutes and conveyors greased per day.

- Amount of grease used per day.

- Number of breakdowns caused by lubrication issues.

8. What are the opportunities for professional development for a Chute Greaser?

- Attending training courses on lubrication and maintenance.

- Reading trade publications and articles.

- Participating in professional organizations.

9. What are the challenges that a Chute Greaser may face on the job?

- Working in dirty and dusty environments.

- Working in confined spaces.

- Working with hazardous materials.

- Working long hours.

10. What are the skills and qualifications that a Chute Greaser should possess?

- Basic knowledge of lubrication and maintenance principles.

- Ability to operate and maintain lubrication equipment.

- Ability to inspect and identify worn or damaged parts.

- Ability to follow safety procedures.

- Ability to work independently and as part of a team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chute Greaser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chute Greaser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chute Greaser is a highly skilled professional who is responsible for maintaining the proper lubrication of industrial chutes to allow materials to flow smoothly through production lines. Understanding the critical role of this position will help candidates prepare effectively for their interview.

1. Lubrication Maintenance

The primary duty of a Chute Greaser is to ensure that all chutes and associated equipment are adequately lubricated. This involves:

- Applying grease to chutes, bearings, and other moving parts

- Monitoring lubrication levels and replenishing grease as needed

- Inspecting chutes for leaks or other issues

2. Chute Inspection and Maintenance

In addition to lubrication, Chute Greasers are responsible for the general maintenance and inspection of chutes:

- Checking for wear or damage to chutes and their components

- Cleaning and clearing chutes to prevent blockages

- Repairing or replacing worn or damaged parts

3. Equipment Monitoring and Reporting

Chute Greasers are often responsible for monitoring and reporting on the condition of equipment under their care.

- Logging and maintaining a record of lubrication activities

- Reporting any equipment issues or malfunctions to supervisors

- Assisting in the troubleshooting and repair of any equipment issues

4. Workplace Safety

Maintaining a safe work environment is essential for Chute Greasers. Their responsibilities include:

- Adhering to all safety regulations and procedures

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

- Reporting any potential safety hazards

Interview Tips

Interview preparation is crucial for success in a Chute Greaser interview. Here are some tips to help candidates stand out:

1. Research the Company and Role

Candidates should thoroughly research the company and the specific Chute Greaser position they are applying for. This will help them understand the company’s culture, business goals, and the specific requirements of the role. Understanding these points will help you provide tailored responses that align with the interviewer’s expectations.

2. Highlight Relevant Skills and Experience

Candidates should highlight their technical skills and experience in chute lubrication, maintenance, and repair. Use specific examples to demonstrate their abilities. Quantifying your accomplishments with specific metrics will make your responses even more compelling. For instance, instead of saying “I lubricated chutes,” mention “I lubricated 12 chutes resulting in a 15% increase in production efficiency.”

3. Practice Common Interview Questions

Prepare for common interview questions related to Chute Greaser responsibilities, safety procedures, and problem-solving abilities. Jot down your answers to build confidence and practice delivering them clearly and concisely. You can find potential interview questions online or consult industry-specific forums. Practicing will help you stay calm during the actual interview and present your thoughts effectively.

4. Be Enthusiastic and Professional

Maintain a positive and enthusiastic attitude throughout the interview. Dress professionally and arrive on time, demonstrating respect for the interviewers and the company. Nonverbal cues, such as maintaining eye contact and having a firm handshake, also make a significant impression. Being polite, respectful, and asking thoughtful questions at the end of the interview shows your interest and engagement in the role and the company.

Next Step:

Now that you’re armed with the knowledge of Chute Greaser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Chute Greaser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini