Are you gearing up for a career in Chute Tapper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chute Tapper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

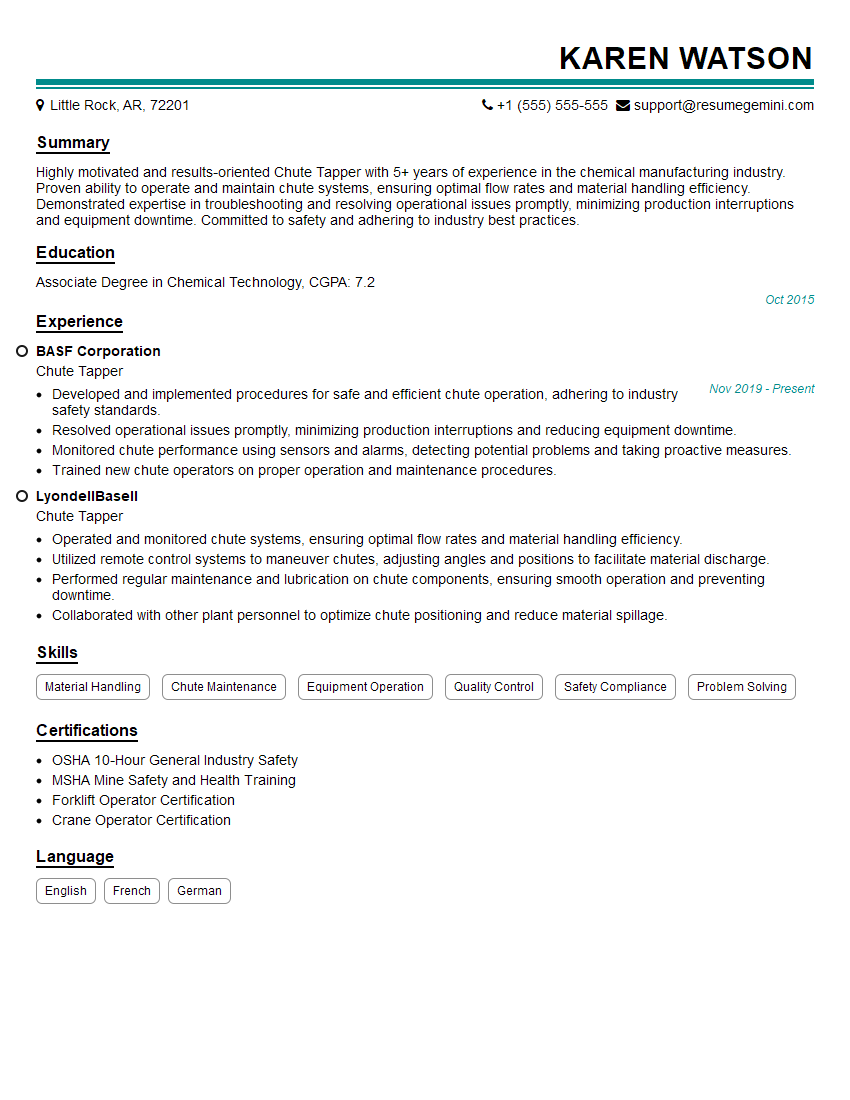

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chute Tapper

1. Explain the concept of a chute tapper and its importance in the chutes loading and unloading process?

A chute tapper is a mechanical device that is used to keep the material flowing smoothly through a chute by applying continuous vibration. It is a vital component of many loading and unloading systems, as it helps to prevent blockages and ensures that the material is delivered to the desired location at the correct rate.

- Chute tapper helps keep chute walls clean, promote material flow and prevent blockages.

- It increases the efficiency of the loading and unloading process.

- Reduces downtime and maintenance costs.

2. Describe the different types of chute tappers available in the market and highlight the advantages and disadvantages of each type?

Hydraulic Chute Tappers

- High force output but require a hydraulic power unit, which can be costly and complex to maintain.

- Suitable for heavy-duty applications where high vibration force is required.

Pneumatic Chute Tappers

- Compact design, easy to install and maintain.

- Requires a compressed air supply, which may not always be available in all environments.

- Limited force output compared to hydraulic tappers.

Electromagnetic Chute Tappers

- Generate vibration using electromagnetic force, providing precise control over frequency and amplitude.

- No external power source required, making them suitable for hazardous environments.

- Can be more expensive than other types of tappers.

3. How would you determine the appropriate size and type of chute tapper for a specific application?

- Consider the material characteristics such as particle size, density, and flowability.

- Calculate the required vibration force based on the material properties and chute dimensions.

- Select the type of tapper (hydraulic, pneumatic, or electromagnetic) based on the application requirements and available resources.

- Ensure that the tapper is compatible with the chute material and environment.

4. Explain the installation and maintenance procedures for a chute tapper?

Installation

- Mount the tapper securely to the chute using appropriate fasteners.

- Connect the tapper to the power source or compressed air supply.

- Tune the tapper frequency and amplitude to optimize material flow.

Maintenance

- Regularly check the tapper for any signs of damage or wear.

- Replace worn or damaged components as needed.

- Inspect and clean the chute walls to remove any material buildup.

5. Discuss the importance of safety considerations when working with chute tappers?

- Always wear appropriate personal protective equipment (PPE) when working with chute tappers.

- Ensure that the chute and tapper are properly grounded to prevent electrical hazards.

- Be aware of the potential for material spills or dust emissions.

- Follow all manufacturer’s instructions and safety guidelines.

6. What troubleshooting techniques would you use to identify and resolve common problems associated with chute tappers?

- Check the power supply or compressed air supply to ensure it is adequate.

- Inspect the tapper for any loose connections or damaged components.

- Adjust the tapper frequency and amplitude to optimize performance.

- Clean the chute walls to remove any material buildup that may be causing blockages.

7. How would you approach designing a chute tapper for a specific application that requires precise control over material flow?

- Analyze the material properties and flow requirements.

- Determine the required vibration force and frequency range.

- Select appropriate tapper technology (hydraulic, pneumatic, or electromagnetic) and size the tapper accordingly.

- Design the tapper mounting system to ensure effective vibration transmission.

- Incorporate sensors and control systems to monitor and adjust vibration parameters.

8. Explain how the choice of tapper material can affect the performance and longevity of the tapper in different operating environments?

- Materials such as stainless steel provide corrosion resistance and durability in harsh environments.

- Aluminum alloys offer a lightweight and cost-effective option for less demanding applications.

- Polymers can be used for applications where electrical insulation or noise reduction is important.

- The choice of material should consider factors such as temperature, chemical exposure, and mechanical wear.

9. Discuss the advantages of using multiple chute tappers in a single chute system?

- Improved material flow and reduced blockages.

- Optimization of vibration patterns for different material characteristics.

- Redundancy in case of a single tapper failure.

- Enhanced control over material flow rate and consistency.

10. How would you evaluate the effectiveness of a chute tapper installation based on performance metrics?

- Measure material flow rate and consistency.

- Monitor chute wall cleanliness and material buildup.

- Analyze vibration patterns and adjust parameters as needed.

- Collect feedback from operators and maintenance personnel.

- Compare performance data to baseline measurements to quantify improvements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chute Tapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chute Tapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chute Tapper plays a pivotal role in the efficient and safe operation of a chute system used for conveying materials in various industrial settings. Their primary responsibilities include:

1. Ensuring Smooth Material Flow

Chute Tappers are responsible for monitoring the material flow through the chute system and taking prompt action to prevent blockages or flow interruptions. They:

- Inspect chutes regularly to identify potential issues, such as material build-up or equipment malfunctions.

- Use specialized tools, such as hammers or rods, to tap the chute walls to dislodge any blockages and maintain a steady material flow.

2. Maintaining Equipment and Safety

Chute Tappers are responsible for ensuring the proper functioning and safety of the chute system:

- Perform routine maintenance and repairs on chute components, such as replacing worn-out liners or repairing damaged gates.

- Inspect and lubricate chute equipment to prevent premature wear and equipment failure.

- Ensure the safe operation of the chute system by adhering to established safety protocols and reporting any potential hazards.

3. Monitoring and Reporting

Chute Tappers monitor and document the performance of the chute system for quality control and troubleshooting purposes:

- Record material flow rates, equipment performance, and any incidents or maintenance activities.

- Report any deviations from normal operating parameters or potential system issues to supervisors or designated personnel.

4. Communication and Collaboration

Chute Tappers work closely with other team members to ensure the smooth operation of the plant:

- Communicate with operators, maintenance personnel, and supervisors to coordinate maintenance activities and resolve any issues.

- Collaborate with engineers to identify and implement improvements to the chute system’s efficiency and safety.

Interview Preparation Tips

To ace an interview for a Chute Tapper position, candidates should thoroughly prepare and demonstrate their skills and knowledge. Here are some interview preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s profile, industry trends, and the specific role requirements. This will help you tailor your answers and show that you have a genuine interest in the position.

2. Practice Answering Common Interview Questions

Prepare for typical interview questions related to your skills, experience, and the role’s responsibilities. Practice your answers in advance to deliver them confidently and clearly.

3. Highlight Your Relevant Experience and Skills

Emphasize your previous experience in operating, monitoring, and maintaining chute systems or similar equipment. Quantify your accomplishments whenever possible to demonstrate your impact.

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview demonstrates your engagement and interest in the position. Prepare questions related to the company’s operations, safety protocols, or growth opportunities.

5. Be Prepared to Discuss Safety Measures

Chute systems often involve potential safety hazards. Be ready to discuss your understanding of safety regulations and your commitment to maintaining a safe work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Chute Tapper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.