Are you gearing up for a career in Cigar Making Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cigar Making Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

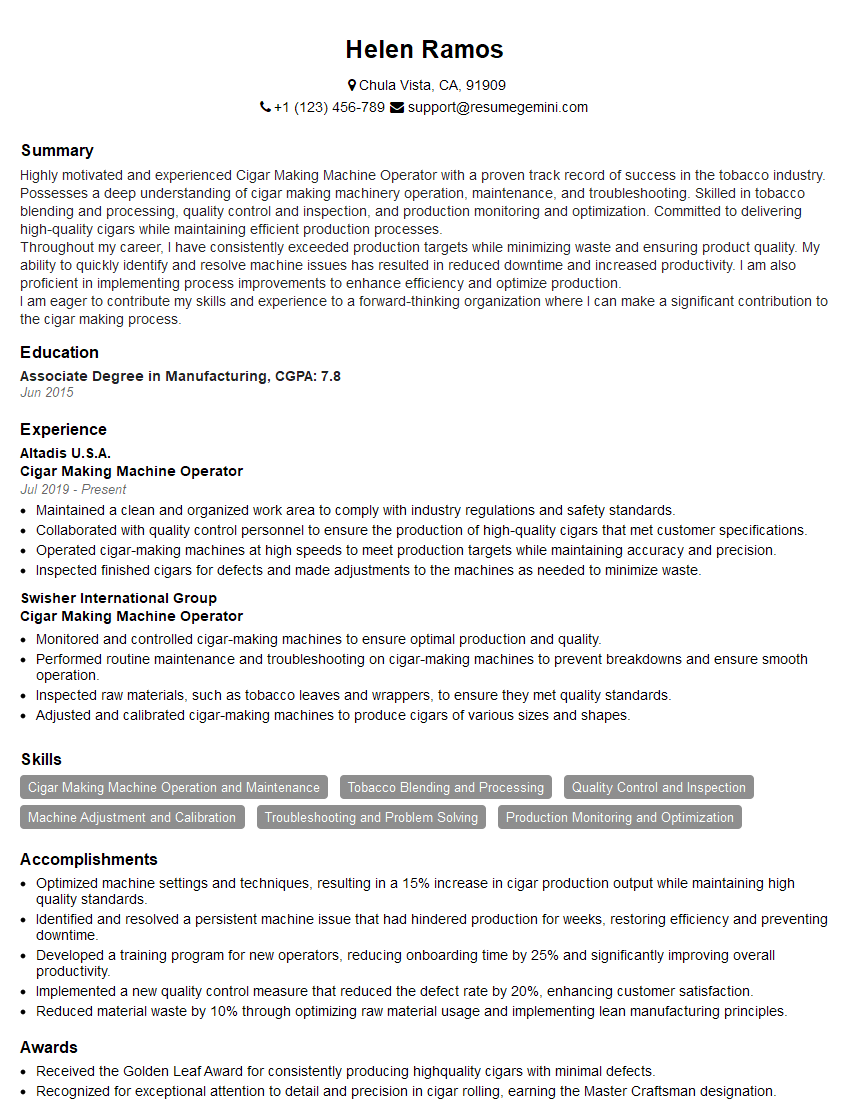

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cigar Making Machine Operator

1. Describe the key components of a cigar making machine and explain how they work together to produce cigars?

- Tobacco Feeder: Feeds tobacco leaves into the machine.

- Binder Wrapper Roller: Wraps the binder and wrapper leaves around the tobacco filler.

- Cutter: Cuts the cigars to the desired length.

- Tipper: Applies adhesive to the cigar tips.

2. Explain the process of calibrating a cigar making machine?

Roll Density Calibration

- Set the proper roll density settings on the machine.

- Adjust the feeder to ensure even distribution of tobacco filler.

Cut Length Calibration

- Use a cutting gauge to set the desired cigar length.

- Adjust the cutting knife to ensure accurate cuts.

3. How do you troubleshoot common problems with a cigar making machine, such as uneven rolls or loose wrappers?

- Uneven Rolls: Check tobacco feeder, adjust settings as needed.

- Loose Wrappers: Inspect wrapper tension settings, apply adhesive as required.

4. Describe the maintenance procedures for a cigar making machine?

- Clean and lubricate all moving parts.

- Inspect and replace worn or damaged components.

- Calibrate the machine regularly.

5. What are the safety precautions that should be followed when operating a cigar making machine?

- Wear appropriate safety gear (gloves, eye protection).

- Keep hands away from moving parts.

- Never attempt to operate the machine when it is malfunctioning.

6. What is the ideal humidity and temperature range for storing cigars?

- Humidity: 65-75%

- Temperature: 65-72°F (18-22°C)

7. What are the different types of cigar wrappers and how do they affect the flavor and aroma of the cigar?

- Connecticut: Mild and smooth

- Corojo: Spicy and earthy

- Habano: Rich and full-flavored

8. What is the difference between a long-filler cigar and a short-filler cigar?

- Long-Filler: Made with whole tobacco leaves, resulting in a smoother and more flavorful smoke.

- Short-Filler: Composed of chopped tobacco pieces, resulting in a shorter and less flavorful smoke.

9. What is the best way to cut a cigar?

- Use a sharp cigar cutter.

- Cut straight across the cap, slightly above the shoulder.

10. What are the different ways to smoke a cigar?

- Straight Cut: Inhale the smoke directly from the cut end.

- Punch Cut: Punch a small hole in the cap and inhale from the side.

- V-Cut: Cut a V-shaped notch in the cap and inhale from the point.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cigar Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cigar Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cigar Making Machine Operators are responsible for operating and maintaining cigar making machines to produce cigars. They ensure the machines are operating efficiently and producing cigars of the desired quality and quantity.

1. Machine Operations

- Set up and operate cigar making machines according to specifications

- Monitor machine performance and make adjustments as needed

- Troubleshoot and resolve machine problems

2. Quality Control

- Inspect cigars for defects and ensure they meet quality standards

- Calibrate and maintain inspection equipment

- Identify and correct production issues to prevent defects

3. Production Monitoring

- Monitor production output and report any deviations from targets

- Maintain production records and track machine performance

- Suggest improvements to increase efficiency and reduce downtime

4. Maintenance and Cleaning

- Perform routine maintenance and cleaning on cigar making machines

- Lubricate moving parts and replace worn components

- Ensure machines are clean and sanitized to prevent contamination

Interview Tips

Preparing for an interview for a Cigar Making Machine Operator position requires understanding the job responsibilities and showcasing relevant skills and experience. Follow these tips to enhance your chances of success:

1. Research the Company and Industry

- Learn about the cigar manufacturing company and its products

- Research the current trends and advancements in the cigar industry

- Identify any specific requirements or certifications relevant to the position

2. Highlight Relevant Skills and Experience

- Emphasize your experience in operating and maintaining cigar making machines

- Quantify your accomplishments in terms of production efficiency and quality control

- Showcase your ability to troubleshoot and resolve machine issues effectively

3. Prepare for Technical Questions

- Be familiar with the different types of cigar making machines and their operations

- Understand the principles of cigar manufacturing, including tobacco blending and wrapping

- Anticipate questions about maintenance and calibration procedures for cigar making machines

4. Demonstrate Attention to Detail and Quality

- Highlight your attention to detail and commitment to maintaining high-quality standards

- Describe examples of how you have identified and corrected production problems

- Explain your approach to ensuring the cleanliness and sanitation of cigar making equipment

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cigar Making Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!