Are you gearing up for a career in Cigar Making Machine Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cigar Making Machine Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

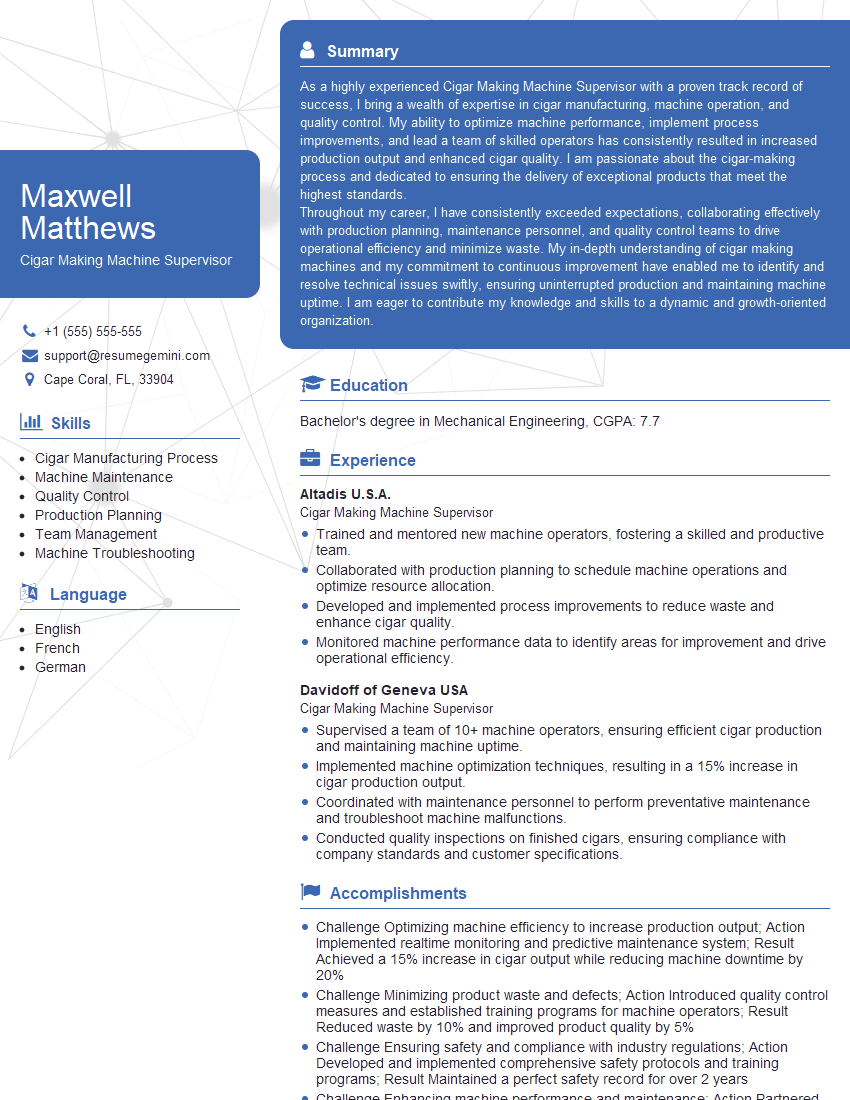

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cigar Making Machine Supervisor

1. How do you ensure that the cigar making machines are operating at optimal efficiency and productivity levels?

To ensure optimal efficiency and productivity levels, I follow a comprehensive approach:

- Regular Maintenance: I establish a preventive maintenance schedule to proactively identify and address potential issues, minimizing downtime and maintaining peak performance.

- Performance Monitoring: I monitor key performance indicators such as cycle time, defect rates, and output volumes to identify areas for improvement.

- Operator Training: I provide thorough training to operators on proper machine operation, troubleshooting techniques, and quality standards to enhance proficiency.

2. Describe the quality control measures you have implemented to ensure the production of high-quality cigars?

Process Control:

- Raw Material Inspection: I conduct thorough inspections of incoming tobacco leaves to ensure they meet quality specifications.

- In-Process Monitoring: I monitor machines throughout the production process to identify and correct any deviations from quality standards.

Product Inspection:

- Visual Inspection: I conduct random visual inspections of finished cigars to check for defects, consistency, and compliance with aesthetic standards.

- Draw Resistance Testing: I use specialized equipment to measure the draw resistance of cigars, ensuring they meet the desired specifications.

- Burn Testing: I conduct burn tests to assess the uniformity and quality of the cigar’s burn.

3. How do you manage the production schedule to meet customer demands while minimizing waste and optimizing resources?

I employ a multifaceted approach to production scheduling:

- Demand Forecasting: I analyze historical data and industry trends to forecast demand levels.

- Capacity Planning: I assess machine capacity and operator availability to ensure we can meet production targets.

- Scheduling Optimization: I use software tools to optimize the scheduling process, considering lead times, machine capabilities, and resource availability.

- Waste Reduction Strategies: I implement lean manufacturing techniques to minimize waste, such as reducing setup times and improving inventory management.

4. Can you elaborate on the safety procedures and protocols you enforce to maintain a safe and compliant work environment?

I prioritize safety by implementing comprehensive procedures and protocols:

- Hazard Identification and Risk Assessment: I conduct thorough risk assessments to identify potential hazards and develop mitigation strategies.

- Training and Education: I provide regular safety training to employees, emphasizing safe work practices, emergency procedures, and proper machine operation.

- Safety Inspections: I conduct regular inspections of equipment, facilities, and work areas to identify and address any potential hazards.

- Emergency Preparedness: I develop and implement emergency response plans to ensure the safety of employees in case of unexpected events.

5. Describe your experience in troubleshooting and resolving technical issues related to cigar making machines?

I possess extensive experience in troubleshooting and resolving technical issues related to cigar making machines:

- Electrical Troubleshooting: I can diagnose and repair electrical faults, such as wiring issues, motor failure, and PLC malfunctions.

- Mechanical Troubleshooting: I have experience troubleshooting mechanical problems, such as jammed mechanisms, worn components, and alignment issues.

- Software Troubleshooting: I am proficient in identifying and resolving software issues, such as bugs, configuration errors, and PLC programming problems.

6. How do you stay abreast of industry advancements and best practices in cigar making?

To stay current with industry advancements, I engage in the following:

- Industry Events: I attend trade shows and conferences to learn about new technologies, trends, and best practices.

- Technical Journals and Publications: I subscribe to industry publications and read technical journals to stay informed about innovations and research.

- Vendor Collaboration: I maintain relationships with machine manufacturers and suppliers to gain insights into the latest equipment and solutions.

7. How do you manage a team of operators and ensure their productivity and motivation?

I foster a productive and motivated team environment through the following strategies:

- Clear Communication: I communicate expectations clearly to my team and provide regular feedback.

- Performance Management: I set performance goals and provide ongoing support and mentorship to help my team succeed.

- Recognition and Incentives: I recognize and reward exceptional performance to motivate my team.

- Cross-Training: I encourage cross-training to develop my team’s skills and increase their flexibility.

8. Describe your experience in quality management systems, such as ISO 9001?

I have a deep understanding of quality management systems, including ISO 9001:

- Quality Documentation: I am responsible for maintaining and updating quality documentation, such as procedures, manuals, and records.

- Internal Audits: I conduct internal audits to assess compliance with quality standards and identify areas for improvement.

- Continuous Improvement: I am committed to ongoing improvement and use quality tools and techniques to enhance processes.

9. How do you handle customer complaints and ensure customer satisfaction?

I prioritize customer satisfaction and handle complaints promptly and effectively:

- Complaint Investigation: I thoroughly investigate customer complaints to identify the root cause and develop corrective actions.

- Customer Communication: I communicate with customers throughout the complaint resolution process, providing updates and resolutions.

- Problem Resolution: I work closely with relevant departments to implement solutions that address customer concerns and prevent recurrence.

10. What are your long-term career goals, and how do you see this role contributing to your professional development?

My long-term career goal is to become a recognized expert in cigar making technology. I believe this role will contribute to my professional development by:

- Technical Expertise: I will gain in-depth knowledge of cigar making machines, troubleshooting techniques, and quality control processes.

- Leadership Experience: I will have the opportunity to lead and manage a team of operators, enhancing my leadership and communication skills.

- Industry Knowledge: I will stay current with industry advancements and best practices through collaboration with vendors and attendance at industry events.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cigar Making Machine Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cigar Making Machine Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cigar Making Machine Supervisor plays a crucial role in overseeing the daily operations of a cigar manufacturing plant, ensuring efficient production and quality control.

1. Production Management

Supervises and coordinates the production team, assigning tasks, monitoring progress, and ensuring adherence to quality standards.

- Establishes and implements production schedules and goals.

- Monitors machine performance, makes adjustments, and troubleshoots any breakdowns.

2. Quality Assurance

Ensures that all cigars meet the required specifications and standards, conducting regular inspections and implementing quality control measures.

- Inspects raw materials to ensure they meet quality requirements.

- Collaborates with the quality control department to identify and resolve any quality issues.

3. Inventory Management

Manages inventory levels of raw materials, supplies, and finished goods, ensuring sufficient stock for production and optimal storage conditions.

- Orders and receives raw materials and supplies.

- Tracks finished goods inventory and reports shortages or surpluses.

4. Employee Supervision

Supervises and motivates a team of production workers, providing guidance, training, and performance evaluations.

- Conducts regular performance reviews and provides feedback to employees.

- Maintains a positive and productive work environment.

Interview Tips

Preparing thoroughly for an interview is crucial. Here are some tips to help you ace the interview for the Cigar Making Machine Supervisor position:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and values. Research the specific responsibilities of the Cigar Making Machine Supervisor role and understand the industry.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on trends.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Focus on highlighting your skills and experience that align with the job requirements.

- Prepare examples of how you’ve managed production teams, implemented quality control measures, or solved complex problems.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Showcase Your Technical Expertise

Emphasize your knowledge of cigar-making machines and their maintenance. Explain how you’ve identified and resolved machine issues in the past.

- Highlight any certifications or training you have in cigar-making machine operation.

- Discuss your experience with different types of machines.

4. Demonstrate Leadership and Communication Skills

Supervisory roles require strong leadership and communication abilities. Provide examples of how you’ve effectively motivated and guided teams.

- Describe your approach to performance management and employee development.

- Explain how you resolve conflicts and foster a positive work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cigar Making Machine Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!