Are you gearing up for a career in Cigar Tobacco Processing Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cigar Tobacco Processing Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

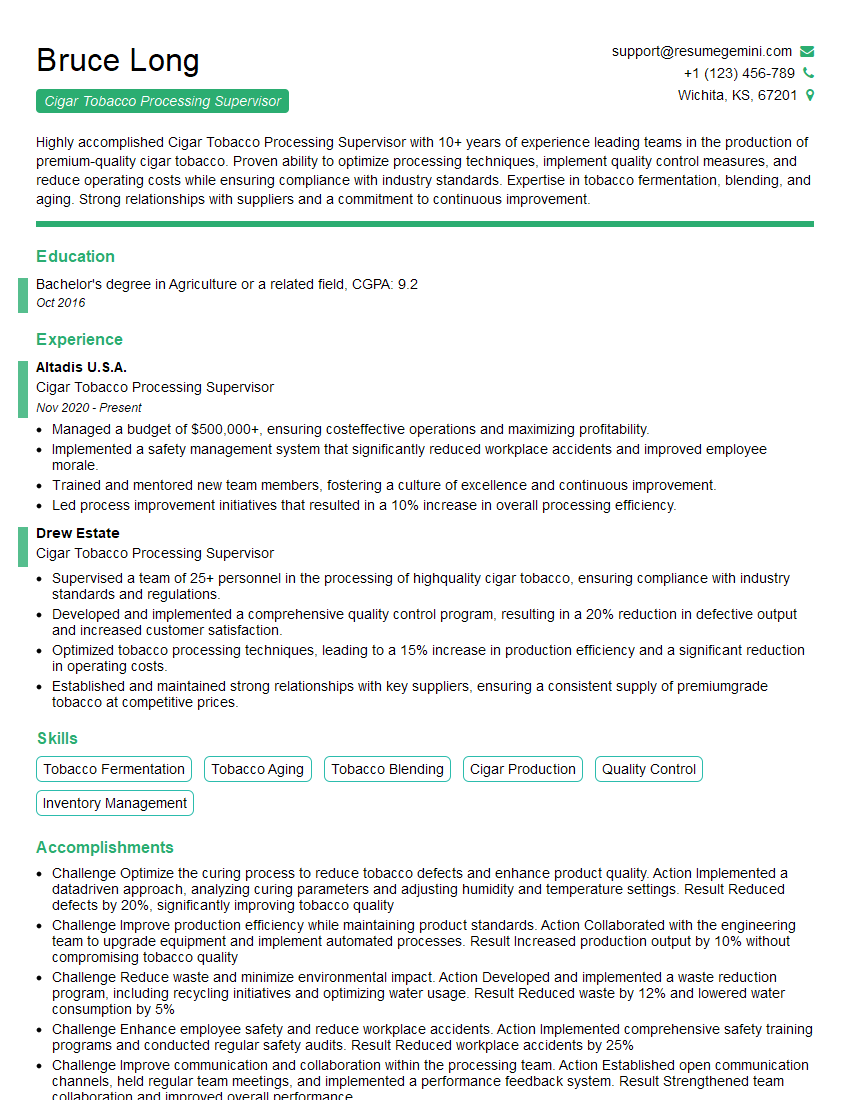

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cigar Tobacco Processing Supervisor

1. Can you explain the process of Cigar Tobacco Processing?

- The process of cigar tobacco processing is a complex and delicate one that requires careful attention to detail.

- It begins with the harvesting of the tobacco leaves, which are then sorted and graded according to their quality.

- The leaves are then fermented, a process that helps to develop their flavor and aroma.

- After fermentation, the leaves are dried and aged, which further enhances their flavor and quality.

- The final step in the process is blending, where different types of tobacco are combined to create the desired flavor profile.

2. What are the key factors that affect the quality of Cigar Tobacco?

- The quality of cigar tobacco is affected by a number of factors, including the climate, soil, and growing conditions.

- The type of tobacco plant, the harvesting process, and the fermentation and aging process also play a role.

subheading of the answer

- In order to produce high-quality cigar tobacco, it is important to carefully control all of these factors.

subheading of the answer

- Experienced cigar tobacco processors have a deep understanding of the factors that affect tobacco quality and are able to make the necessary adjustments to ensure that the tobacco they produce meets the highest standards.

3. What are the different types of Cigar Tobacco?

- There are many different types of cigar tobacco, each with its own unique flavor and aroma.

- Some of the most popular types of cigar tobacco include:

- Cuban tobacco: Cuban tobacco is known for its rich, full-bodied flavor and is considered to be some of the best in the world.

- Dominican tobacco: Dominican tobacco is known for its mild, smooth flavor and is often used in premium cigars.

- Nicaraguan tobacco: Nicaraguan tobacco is known for its spicy, peppery flavor and is often used in full-bodied cigars.

- Honduran tobacco: Honduran tobacco is known for its light, sweet flavor and is often used in mild- to medium-bodied cigars.

4. What are the challenges involved in Cigar Tobacco Processing?

- There are a number of challenges involved in cigar tobacco processing, including:

- Climate and weather conditions: Climate and weather conditions can have a significant impact on the quality of cigar tobacco.

- Pests and diseases: Pests and diseases can damage tobacco plants and reduce the quality of the tobacco.

- Fermentation and aging: The fermentation and aging process is critical to the development of the tobacco’s flavor and aroma.

- Blending: Blending different types of tobacco to create the desired flavor profile is a complex and challenging task.

5. What are the latest technologies used in Cigar Tobacco Processing?

- A number of new technologies are being used in cigar tobacco processing, including:

- Automated harvesting machines: Automated harvesting machines can help to improve the efficiency and quality of the tobacco harvest.

- Computer-controlled fermentation chambers: Computer-controlled fermentation chambers can help to precisely control the fermentation process and improve the quality of the tobacco.

- Advanced blending techniques: Advanced blending techniques can help to create more consistent and flavorful cigars.

6. What are the quality control measures used in Cigar Tobacco Processing?

- A number of quality control measures are used in cigar tobacco processing, including:

- Visual inspection: Tobacco leaves are visually inspected for any defects.

- Chemical analysis: Tobacco leaves are chemically analyzed to ensure that they meet the desired quality standards.

- Sensory evaluation: Tobacco leaves are sensually evaluated to assess their flavor and aroma.

7. What are the safety precautions that must be taken when working with Cigar Tobacco?

- A number of safety precautions must be taken when working with cigar tobacco, including:

- Wearing protective clothing: Protective clothing, such as gloves and masks, should be worn to prevent contact with tobacco dust and other irritants.

- Ventilating work areas: Work areas should be well-ventilated to prevent the buildup of tobacco dust and other irritants.

- Avoiding contact with eyes and skin: Contact with tobacco dust and other irritants should be avoided, as it can cause irritation and allergic reactions.

8. What are the environmental regulations that apply to Cigar Tobacco Processing?

- A number of environmental regulations apply to cigar tobacco processing, including:

- Air pollution control: Air pollution control regulations limit the amount of pollutants that can be released into the air during tobacco processing.

- Water pollution control: Water pollution control regulations limit the amount of pollutants that can be discharged into water during tobacco processing.

- Waste management: Waste management regulations govern the disposal of tobacco processing waste.

9. What are the skills and qualifications required to be a successful Cigar Tobacco Processing Supervisor?

- A successful Cigar Tobacco Processing Supervisor should have the following skills and qualifications:

- Technical knowledge of cigar tobacco processing: A deep understanding of the cigar tobacco processing process is essential.

- Supervisory experience: Experience in supervising a team of employees is required.

- Quality control experience: Experience in implementing and maintaining quality control procedures is essential.

- Safety knowledge: Knowledge of safety regulations and procedures is essential.

- Communication and interpersonal skills: Excellent communication and interpersonal skills are essential for working with employees, customers, and suppliers.

10. What are the career advancement opportunities for Cigar Tobacco Processing Supervisors?

- Career advancement opportunities for Cigar Tobacco Processing Supervisors include:

- Production manager: Production managers are responsible for overseeing the entire cigar tobacco processing operation.

- Quality assurance manager: Quality assurance managers are responsible for developing and implementing quality control procedures.

- Plant manager: Plant managers are responsible for the overall operation of a cigar tobacco processing plant.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cigar Tobacco Processing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cigar Tobacco Processing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cigar Tobacco Processing Supervisor is responsible for overseeing the processing of tobacco for use in cigar production. This involves managing a team of workers and ensuring that the tobacco is processed in accordance with quality standards. The supervisor must also be able to identify and resolve problems with the processing equipment.

1. Managing a team of workers

The supervisor must be able to effectively lead and motivate a team of workers. This includes providing clear instructions, assigning tasks, and providing feedback on performance. The supervisor must also be able to resolve conflicts between workers and maintain a positive work environment.

2. Ensuring that the tobacco is processed in accordance with quality standards

The supervisor must be familiar with the quality standards for cigar tobacco. This includes knowing the correct moisture content, color, and aroma of the tobacco. The supervisor must also be able to identify and remove any foreign objects from the tobacco.

3. Identifying and resolving problems with the processing equipment

The supervisor must be able to identify and resolve problems with the processing equipment. This includes being able to diagnose problems, make repairs, and order new parts. The supervisor must also be able to work with other departments to resolve problems that are beyond their area of expertise.

4. Maintaining a safe and clean work environment

The supervisor must be able to maintain a safe and clean work environment. This includes ensuring that the work area is free of hazards, that the equipment is properly maintained, and that the workers are wearing appropriate safety gear. The supervisor must also be able to respond to emergencies and accidents.

Interview Tips

Preparing for an interview can be daunting, but by following a few simple tips, you can increase your chances of success.

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture, its products or services, and its goals. You should also learn as much as you can about the specific position you are applying for, including the job responsibilities, qualifications, and salary range.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?”, and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. You can also prepare for questions specific to the cigar tobacco industry, such as “What are the key factors that affect the quality of cigar tobacco?” or “What are the different types of cigar tobacco processing methods?”

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late can make a negative impression on the interviewer. If you are running late, be sure to call or email the interviewer to let them know.

4. Be enthusiastic and positive

The interview is your chance to sell yourself, so it is important to be enthusiastic and positive throughout the process. This does not mean that you should be over the top, but you should be confident in your abilities and excited about the opportunity to work for the company.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer to thank them for their time and to reiterate your interest in the position. You can do this by sending a handwritten thank-you note or an email. You can also use this opportunity to address any questions that the interviewer may have had during the interview or to provide any additional information that you think may be helpful.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cigar Tobacco Processing Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!