Feeling lost in a sea of interview questions? Landed that dream interview for Cigarette Machine Filler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cigarette Machine Filler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

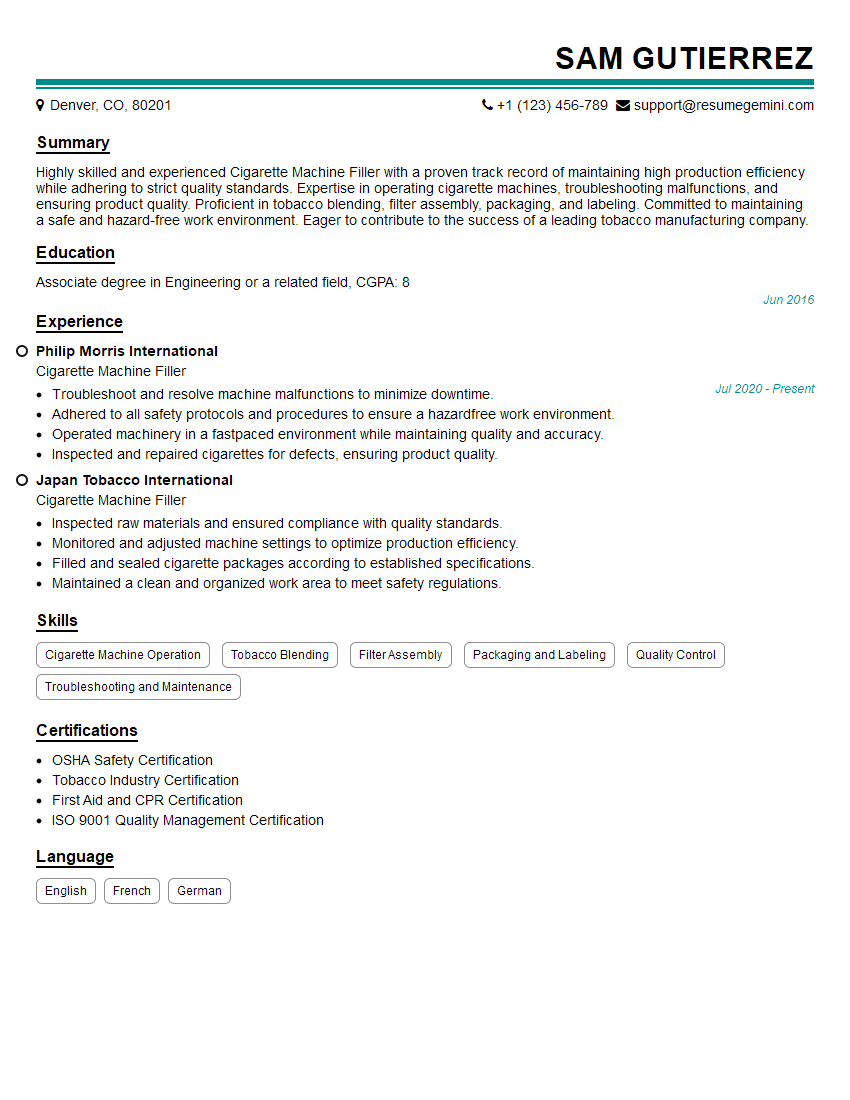

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cigarette Machine Filler

1. Explain the process of filling cigarettes using a cigarette machine.

The process of filling cigarettes using a cigarette machine involves several steps:

- Loading the tobacco: The tobacco is loaded into the hopper of the machine.

- Forming the rod: The tobacco is fed into the forming tube, where it is compressed and shaped into a cylindrical rod.

- Cutting the rod: The rod is cut into individual cigarettes of the desired length.

- Filling the cigarettes: The cut tobacco is transferred to the filling chamber, where it is packed into the cigarette tubes.

- Tipping the cigarettes: A filter is attached to the end of each cigarette using a tipping machine.

- Packing the cigarettes: The cigarettes are packed into cartons or other packaging materials.

2. What are the key components of a cigarette machine and their functions?

Tobacco hopper:

- Holds the tobacco supply.

- Feeds the tobacco into the forming tube.

Forming tube:

- Compresses and shapes the tobacco into a rod.

- Determines the diameter and density of the cigarette.

Cutting blade:

- Cuts the tobacco rod into individual cigarettes.

- Ensures consistent cigarette length.

Filling chamber:

- Holds the cut tobacco.

- Packs the tobacco into the cigarette tubes.

Tipping machine:

- Attaches filters to the cigarettes.

- Ensures proper filter placement and alignment.

3. How do you troubleshoot common problems that occur during cigarette machine operation?

Common problems during cigarette machine operation include:

- Tobacco jams: Inspect the hopper, forming tube, and cutting blade for blockages or damage.

- Uneven filling: Check the filling chamber for proper alignment and adjust the packing pressure.

- Tipping issues: Ensure the filters are properly loaded and the tipping machine is functioning correctly.

- Electrical malfunctions: Inspect the electrical connections and components for damage or loose connections.

- Mechanical breakdowns: Check for worn or damaged parts that may need replacement or repair.

4. What maintenance procedures are necessary to ensure the optimal performance of a cigarette machine?

- Regular cleaning of the hopper, forming tube, filling chamber, and tipping machine.

- Inspection and lubrication of moving parts.

- Calibration and adjustment of cutting blade and filling pressure.

- Monitoring of electrical components and connections.

- Replacement of worn or damaged parts as needed.

5. Describe the safety precautions that must be observed when operating a cigarette machine.

- Wear appropriate safety gear, including gloves and eye protection.

- Operate the machine in a well-ventilated area.

- Keep hands and loose clothing away from moving parts.

- Follow proper lockout/tagout procedures during maintenance and repairs.

- Report any malfunctions or potential hazards to a supervisor immediately.

6. How do you optimize the efficiency and productivity of a cigarette machine?

- Ensure proper machine setup and calibration.

- Use high-quality tobacco and materials.

- Monitor the machine’s performance and make adjustments as needed.

- Implement preventive maintenance schedules.

- Train operators on proper machine operation and maintenance.

7. What are the different types of cigarette machines available?

- Rotary machines: Continuous operation with high production rates.

- Inline machines: Linear operation with lower production rates but greater flexibility.

- Semi-automatic machines: Require manual loading and unloading of materials.

- Automatic machines: Fully automated operation with minimal human intervention.

- Specialized machines: Designed for specific cigarette formats or features, such as slim cigarettes or flavored cigarettes.

8. What are the industry standards for cigarette machine performance and quality control?

- Production output: Measured in cigarettes per minute or hour.

- Cigarette weight: Must meet specified tolerances to ensure consistent nicotine delivery.

- Cigarette length: Must comply with regulations and consumer preferences.

- Tipping quality: Filter attachment must be secure and aesthetically pleasing.

- Packaging integrity: Cigarettes must be properly packed and sealed to prevent damage or contamination.

9. What are the latest technological advancements in cigarette machine design?

- Computerized control systems: Enhance precision and efficiency.

- Sensor technology: Monitors machine performance and detects potential issues.

- Automated quality control: Reduces the risk of defective cigarettes.

- Energy-efficient designs: Reduce operating costs and environmental impact.

- Remote monitoring capabilities: Allow for real-time monitoring and diagnostics.

10. Describe your experience in operating and maintaining cigarette machines.

I have been an operator and maintenance technician for cigarette machines for over 5 years. During this time, I have operated and maintained a variety of machines, including rotary machines, inline machines, and semi-automatic machines. I am proficient in troubleshooting common problems, performing regular maintenance, and ensuring optimal performance and efficiency. I have also received training on the latest technological advancements in cigarette machine design.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cigarette Machine Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cigarette Machine Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cigarette Machine Fillers play a vital role in cigarette manufacturing, where precision and efficiency are paramount. Key reponsibilities include:

1. Machine Operation

Skilled operation of cigarette manufacturing machinery, ensuring smooth production.

- Feeding empty cigarette tubes into the machine

- Monitoring the filling of tobacco into the tubes

2. Quality Control

Maintaining high product quality as per established standards.

- Inspecting cigarettes for defects or imperfections

- Making adjustments to the machine to ensure optimal performance

3. Maintenance and Troubleshooting

Performing basic maintenance and troubleshooting to keep the equipment running smoothly.

- Cleaning and lubricating machinery

- Identifying and resolving minor malfunctions

4. Safety and Compliance

Adhering to established safety procedures and maintaining a clean and organized work environment.

- Using proper personal protective equipment

- Following all safety regulations and protocols

Interview Tips

Preparing thoroughly for your interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Cigarette Machine Filler position:

1. Research the Industry and Company

Develop a good understanding of the tobacco industry, including trends, major players, and the specific company you’re applying to.

- Visit the company’s website and social media pages

- Read industry publications and news articles

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers. Focus on highlighting your skills and experience relevant to the job.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Practice your delivery to ensure clarity and confidence

3. Dress Professionally

First impressions matter, so dress appropriately for the interview. Business attire or smart casual is typically suitable.

- Choose clean, well-fitting clothing

- Consider the company culture and dress accordingly

4. Arrive on Time

Punctuality is essential. Arrive at the interview venue on time to demonstrate your respect for the interviewer’s schedule.

- Plan your route and allow ample time for travel

- Give yourself a buffer in case of unforeseen delays

5. Be Enthusiastic and Positive

Convey your enthusiasm for the role and the industry. A positive attitude can make a strong impression.

- Smile, maintain eye contact, and show interest

- Highlight your passion for manufacturing or working with machinery

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cigarette Machine Filler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!