Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cinder Crusher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

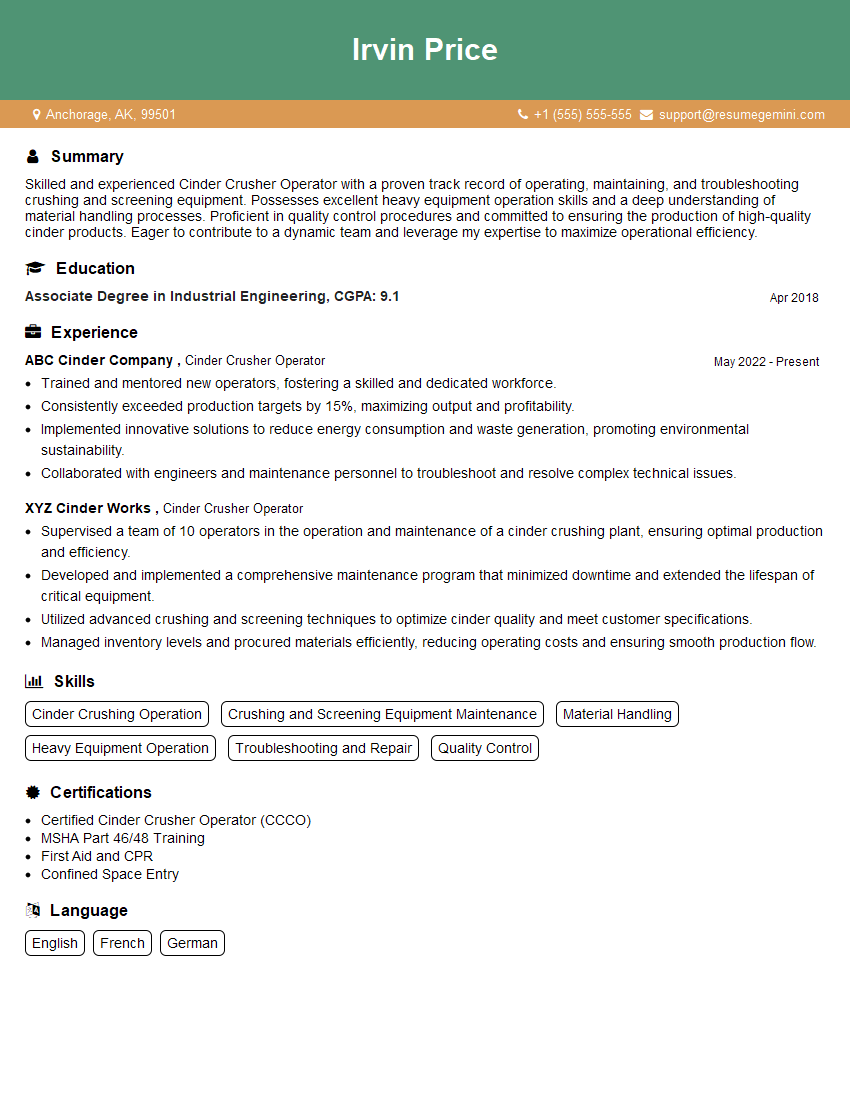

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cinder Crusher Operator

1. Describe the key responsibilities of a Cinder Crusher Operator?

- Operate and maintain cinder crusher equipment to crush and process cinder blocks, ensuring optimal production and quality.

- Monitor and adjust equipment settings, such as feed rate, crusher speed, and screen size, to optimize throughput and product specifications.

- Conduct routine inspections and maintenance procedures on the crusher, conveyor belts, and other equipment, ensuring smooth and efficient operation.

- Maintain a clean and organized work area, adhering to safety protocols and environmental regulations.

- Communicate with supervisors, maintenance personnel, and other operators to coordinate work activities and troubleshoot any issues.

2. Explain the different types of cinder crushers and their specific applications?

Hydraulic Crushers

- Use hydraulic power to crush cinder blocks, providing high-pressure force and precise control.

- Suitable for crushing large blocks and producing uniform-sized products.

Mechanical Crushers

- Utilize gears and rotating hammers to crush cinder blocks, offering high impact force.

- Ideal for crushing smaller blocks and producing a wider range of product sizes.

3. What factors influence the selection of a suitable cinder crusher?

- Size and type of cinder blocks to be crushed.

- Desired output size and shape of the crushed product.

- Production capacity and throughput requirements.

- Availability of power and operating costs.

- Environmental regulations and emission control measures.

4. Describe the safety measures that should be followed when operating a cinder crusher?

- Wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, earplugs, and gloves.

- Maintain a safe distance from moving equipment and rotating parts.

- Lock out and tag out equipment before performing maintenance or repairs.

- Follow established safety protocols for handling hazardous materials, such as dust and chemicals.

- Be aware of potential hazards and take precautions to prevent accidents.

5. How do you calibrate and maintain a cinder crusher to ensure accurate and consistent performance?

- Follow the manufacturer’s guidelines for calibration and maintenance.

- Use precision tools to adjust equipment settings, such as screen mesh size and crusher gap.

- Inspect and replace worn parts, such as screens, hammers, and bearings, to maintain optimal performance.

- Keep the crusher clean and free of debris to prevent blockages and performance issues.

- Monitor production output and adjust settings as needed to meet quality and efficiency targets.

6. What are the potential challenges that you may encounter as a Cinder Crusher Operator and how would you address them?

- Equipment breakdowns: Quickly diagnose the issue, contact maintenance personnel, and take appropriate action to minimize downtime.

- Product quality issues: Adjust equipment settings, check for blockages, and recalibrate as necessary to ensure product meets specifications.

- Environmental concerns: Adhere to emission control measures, minimize dust generation, and follow proper waste management practices.

- Safety hazards: Identify potential risks, implement safety measures, and actively participate in safety training programs.

- Production targets: Collaborate with supervisors and adjust operating parameters to optimize throughput and meet production goals.

7. How do you ensure that the crushed cinder meets the desired specifications and quality standards?

- Monitor the crusher settings and make adjustments as needed to meet product size and shape requirements.

- Conduct regular quality checks on the crushed cinder, using appropriate screening and testing methods.

- Implement quality control measures, such as process audits and feedback loops, to ensure consistency and adherence to standards.

- Collaborate with the quality control team to identify and address any deviations from specifications.

8. Describe the importance of preventive maintenance for a cinder crusher and how you would implement it?

- Reduced downtime: Regular maintenance helps prevent unexpected breakdowns and ensures smooth operation.

- Increased lifespan: Proper maintenance extends the lifespan of the crusher and its components.

- Improved performance: Preventive maintenance helps maintain optimal performance and efficiency.

- Safety: Regular inspections and maintenance reduce the risk of accidents and ensure a safe work environment.

Implementation

- Follow the manufacturer’s recommended maintenance schedule.

- Inspect equipment regularly, looking for signs of wear or damage.

- Conduct routine maintenance tasks, such as cleaning, lubrication, and part replacement.

- Keep a detailed maintenance log to track inspections and repairs.

- Collaborate with maintenance personnel to ensure timely repairs and parts availability.

9. How do you stay updated on the latest advancements and best practices in cinder crushing operations?

- Industry conferences and trade shows: Attend industry events to network, learn about new technologies, and connect with experts.

- Trade publications and online resources: Read industry magazines, articles, and participate in online forums to stay informed about best practices.

- Manufacturer training and webinars: Participate in training sessions and webinars offered by crusher manufacturers to enhance knowledge and skills.

- Collaboration with colleagues and suppliers: Share knowledge and insights with other operators and professionals within the industry.

10. Why are you interested in this Cinder Crusher Operator position, and what strengths and experiences make you a suitable candidate?

I am eager to join your organization as a Cinder Crusher Operator because I am highly proficient in operating and maintaining cinder crushing equipment. My experience in the construction and aggregates industry has equipped me with the technical skills and knowledge necessary for this role.

- Proven ability to operate and maintain cinder crushers: I have a strong track record of operating and maintaining various types of cinder crushers, ensuring optimal performance and production.

- Excellent problem-solving and troubleshooting skills: I am adept at identifying and resolving equipment issues promptly, minimizing downtime and maintaining productivity.

- Commitment to safety and quality: I am committed to maintaining a safe and compliant work environment, and I consistently follow established safety protocols and quality standards.

- Excellent communication and teamwork skills: I am a highly motivated and results-oriented individual, and I work effectively as part of a team or independently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cinder Crusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cinder Crusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cinder Crusher Operator is responsible for operating and maintaining cinder crushing equipment in a plant or quarry. They ensure the safe and efficient operation of the crusher, monitor production levels, and perform routine maintenance and repairs.

1. Operate Cinder Crushing Equipment

The operator’s primary responsibility is to operate the cinder crusher, which involves:

- Starting and stopping the crusher

- Adjusting the crusher settings to meet product specifications

- Monitoring the crusher’s performance and making adjustments as needed

2. Monitor Production Levels

The operator must monitor the production levels of the crusher to ensure that it is meeting targets. This involves:

- Measuring the output of the crusher

- Comparing the output to production targets

- Making adjustments to the crusher settings or operating procedures to improve production levels

3. Perform Routine Maintenance and Repairs

The operator is responsible for performing routine maintenance and repairs on the cinder crusher to keep it in good working condition. This involves:

- Lubricating the crusher’s moving parts

- Inspecting the crusher for wear and tear

- Replacing worn or damaged parts

- Troubleshooting and repairing minor problems

4. Safety and Compliance

The operator must follow all safety procedures and regulations when operating the cinder crusher. This includes:

- Wearing appropriate personal protective equipment

- Following lockout/tagout procedures

- Reporting any unsafe conditions or practices

Interview Tips

To ace an interview for a Cinder Crusher Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills in the following areas:

1. Technical Skills

Candidates should be familiar with the operation and maintenance of cinder crushing equipment. They should also have a good understanding of the principles of crushing and screening. Examples of questions that may be asked to assess technical skills include:

- Describe the different types of cinder crushers and their applications.

- Explain the process of setting up and operating a cinder crusher.

- How do you troubleshoot and repair common problems with cinder crushers?

2. Safety and Compliance

Candidates should be aware of the safety regulations and procedures that apply to the operation of cinder crushers. They should also be able to demonstrate their commitment to safety. Examples of questions that may be asked to assess safety knowledge and compliance include:

- What are the most important safety considerations when operating a cinder crusher?

- Describe the lockout/tagout procedure for the cinder crusher.

- How do you report an unsafe condition or practice?

3. Problem-Solving Skills

Candidates should be able to demonstrate their problem-solving skills by providing examples of how they have identified and resolved problems in a previous role. Examples of questions that may be asked to assess problem-solving skills include:

- Describe a time when you had to troubleshoot and repair a problem with a cinder crusher.

- How do you prioritize your work when you have multiple tasks to complete?

- What is your approach to solving problems that you have not encountered before?

4. Communication and Interpersonal Skills

Candidates should be able to communicate effectively with other employees, supervisors, and customers. They should also be able to work well in a team environment. Examples of questions that may be asked to assess communication and interpersonal skills include:

- How do you communicate with your supervisor to keep them informed of your progress?

- Describe a time when you had to work with a team to solve a problem.

- How do you deal with conflict or disagreements with co-workers?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cinder Crusher Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!