Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Circle Saw Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

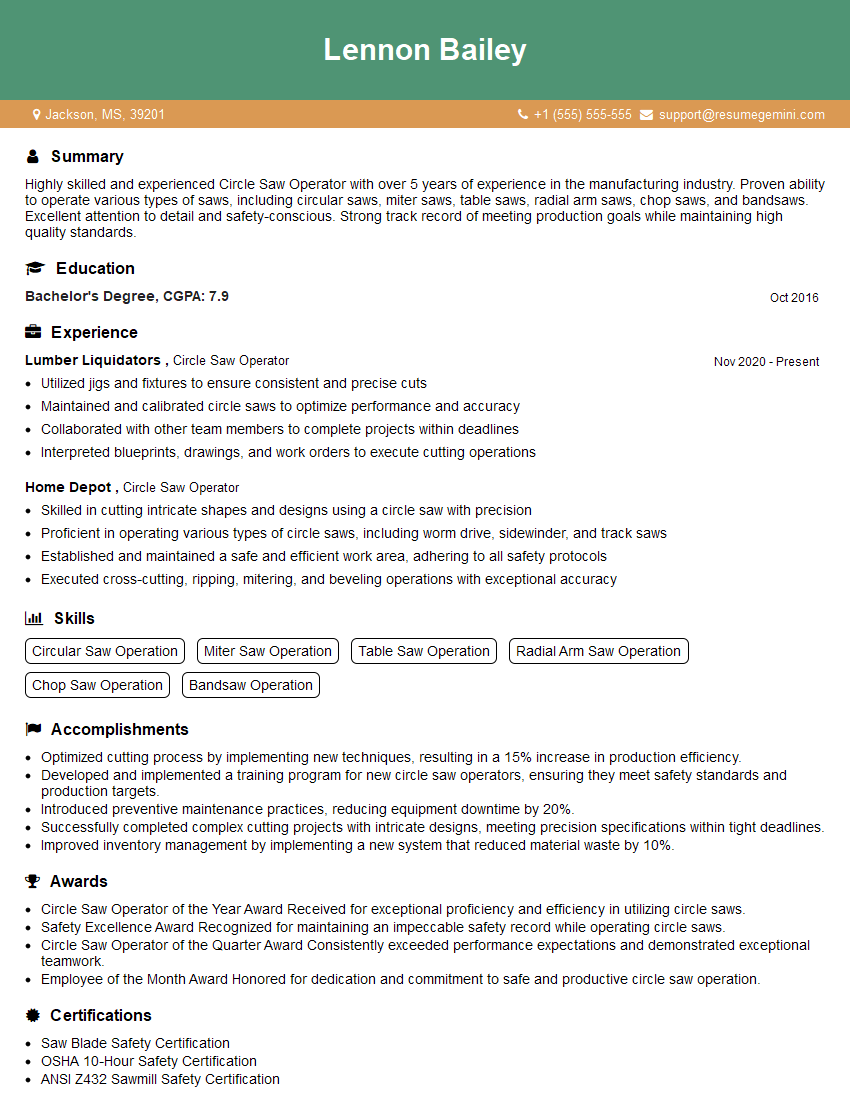

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circle Saw Operator

1. Describe the process of setting up and operating a circle saw for a specific cutting operation.

The process of setting up and operating a circle saw for a specific cutting operation involves several steps:

- Select the appropriate saw blade: The type of blade used will depend on the material being cut and the desired finish.

- Set the blade depth: The blade depth should be set to slightly less than the thickness of the material being cut.

- Adjust the fence: The fence should be positioned parallel to the blade and at the desired distance from the blade.

- Secure the workpiece: The workpiece should be securely clamped to the saw table or placed on a stable surface.

- Position the saw: The saw should be positioned so that the blade will cut through the workpiece at the desired angle.

- Start the saw and feed the workpiece: The saw should be started and the workpiece should be slowly and evenly fed through the blade.

2. What safety precautions should be taken when operating a circle saw?

Personal Protective Equipment

- Wear eye protection

- Wear ear protection

- Wear a dust mask

Saw Operation

- Ensure the saw blade is sharp and in good condition

- Always use a blade guard

- Never cut freehand

- Always use a push stick to feed the workpiece

- Keep hands away from the blade

- Never leave the saw running unattended

3. How do you maintain a circle saw to ensure optimal performance and safety?

- Clean the saw regularly: Remove sawdust and debris from the saw table, blade guard, and other components.

- Lubricate the saw: Lubricate all moving parts according to the manufacturer’s instructions.

- Sharpen the blade: A sharp blade will cut more efficiently and safely.

- Inspect the saw regularly: Check the saw for any damage or wear and tear.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for operating and maintaining the saw.

4. Describe the different types of circle saw blades and their applications.

- Crosscut blades: These blades are designed for cutting across the grain of the wood. They have sharp, pointed teeth that produce a clean cut.

- Ripping blades: These blades are designed for cutting with the grain of the wood. They have flat, angled teeth that produce a smooth cut.

- Combination blades: These blades are designed for both crosscutting and ripping. They have a combination of sharp, pointed teeth and flat, angled teeth.

- Specialty blades: These blades are designed for specific applications, such as cutting metal, plastic, or laminate.

5. How do you determine the correct feed rate for a specific cutting operation?

- Consider the material being cut: Harder materials require a slower feed rate.

- Consider the thickness of the material being cut: Thicker materials require a slower feed rate.

- Consider the type of blade being used: Sharper blades can handle a faster feed rate.

- Start with a slow feed rate and gradually increase it until the desired cut is achieved: A too-fast feed rate can cause the blade to bind and stall.

6. What are the common problems that can occur when operating a circle saw and how do you troubleshoot them?

- The saw blade is binding: This can be caused by a dull blade, a too-fast feed rate, or a warped workpiece.

- The saw blade is vibrating: This can be caused by a loose blade, a bent blade, or an unbalanced blade.

- The saw is not cutting straight: This can be caused by a misaligned fence, a dull blade, or a warped workpiece.

- The saw is overheating: This can be caused by a dull blade, a too-fast feed rate, or a lack of lubrication.

7. Describe the different types of circle saw fences and their applications.

- Standard fence: This is the most common type of fence and is used for general-purpose cutting.

- Self-aligning fence: This type of fence automatically aligns itself with the blade, making it easy to make precise cuts.

- Adjustable fence: This type of fence can be adjusted to different angles, making it ideal for cutting miters and bevels.

- Sliding fence: This type of fence can be slid along the saw table, making it easy to make long cuts.

8. How do you align a circle saw fence?

- Loosen the fence bolts: The fence bolts are located on the front and back of the fence.

- Adjust the fence: Move the fence until it is parallel to the blade.

- Tighten the fence bolts: Once the fence is aligned, tighten the fence bolts.

9. Describe the different types of circle saw tables and their applications.

- Benchtop saw: This type of saw is designed to be mounted on a workbench or table. It is ideal for small projects and hobbyists.

- Cabinet saw: This type of saw is larger and more powerful than a benchtop saw. It is ideal for larger projects and professional woodworkers.

- Contractor saw: This type of saw is a hybrid between a benchtop saw and a cabinet saw. It is ideal for both small and large projects.

- Sliding table saw: This type of saw features a sliding table that allows for precise cutting of large workpieces.

10. How do you choose the right circle saw for your needs?

- Consider the type of projects you will be doing: If you will be working with small or large workpieces, this will affect the size of saw you need.

- Consider the power of the saw: The power of the saw will determine how thick of material you can cut.

- Consider the features of the saw: Some saws have additional features, such as a laser guide or a dust collection system.

- Consider your budget: Circle saws range in price from a few hundred dollars to several thousand dollars.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circle Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circle Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Circle Saw Operators are responsible for operating and maintaining circle saws to cut and shape various materials. They play a crucial role in manufacturing and construction industries, ensuring precise and efficient cutting operations.

1. Saw Operation

Operate and adjust circle saws to cut various materials, including wood, metal, and plastic, based on specifications.

- Set up and configure saw blades, adjusting blade angle, speed, and depth.

- Feed materials into the saw and guide them through the cutting process.

2. Machine Maintenance

Perform regular maintenance and troubleshooting on circle saws, ensuring optimal performance and safety.

- Clean and lubricate saws, replace blades, and check for any wear or damage.

- Inspect and adjust guards, fences, and other safety features to ensure compliance with regulations.

3. Material Handling

Handle and move materials safely and efficiently, minimizing waste and maximizing productivity.

- Load and unload materials, using forklifts or other equipment when necessary.

- Inspect materials for defects or damage before cutting, ensuring quality control.

4. Safety Compliance

Adhere to all safety protocols and regulations, ensuring a safe working environment.

- Wear appropriate safety gear, such as eye protection, gloves, and hearing protection.

- Maintain a clean and organized work area, minimizing hazards.

Interview Tips

Preparing for a Circle Saw Operator interview can help you present your skills and experience effectively. Here are some tips to help you ace the interview.

1. Research the Company and Role

Research the company’s values, industry, and any specific requirements for the role. This will help you tailor your answers and demonstrate your interest in the position.

- Visit the company website and social media pages to learn about their culture and work environment.

- Read industry news and articles to stay updated on trends and best practices.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers. This will help you feel confident and articulate during the interview.

- Example Question: “Tell me about your experience operating circle saws in a manufacturing environment.”

- Example Answer: “In my previous role, I operated a variety of circle saws to cut metal sheets for aircraft components. I was responsible for setting up the saw, adjusting the blade, and ensuring precise cuts within tight tolerances.”

3. Highlight Your Safety Knowledge

Emphasize your knowledge of safety protocols and regulations related to circle saw operation. This is a crucial aspect of the role, and interviewers will want to know that you prioritize safety.

- Example Question: “What are some important safety measures to observe when operating a circle saw?”

- Example Answer: “Always wear appropriate safety gear, maintain a clean and organized work area, and ensure that guards and fences are in place. I also regularly inspect the saw for any damage or wear, and immediately report any issues to my supervisor.”

4. Demonstrate Your Technical Skills

Highlight your technical skills, such as blade adjustment, saw maintenance, and material handling. Use specific examples to demonstrate your proficiency.

- Example Question: “Describe your experience with troubleshooting circle saws.”

- Example Answer: “I recently encountered an issue where the saw was not cutting cleanly. I diagnosed the problem as a dull blade and quickly replaced it, restoring the saw to optimal performance.”

Next Step:

Now that you’re armed with the knowledge of Circle Saw Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Circle Saw Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini