Feeling lost in a sea of interview questions? Landed that dream interview for Circuit Board Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Circuit Board Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

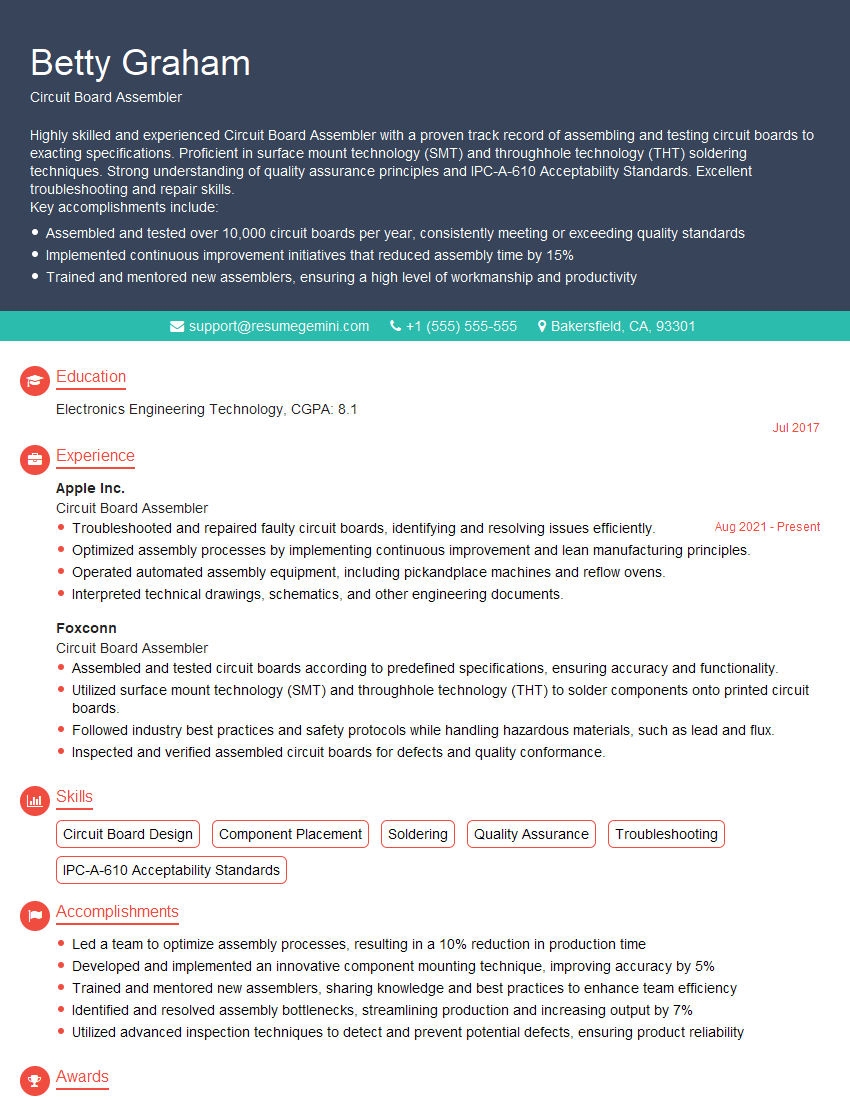

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circuit Board Assembler

1. Describe the different types of circuit boards and their applications?

There are various types of circuit boards, each suited for specific applications. Some common types include:

- Single-sided circuit boards: These boards have conductive traces on one side only and are often used in low-complexity applications such as simple electronic devices.

- Double-sided circuit boards: These boards have conductive traces on both sides, allowing for higher component density and complexity. They are commonly used in consumer electronics and industrial equipment.

- Multilayer circuit boards: These boards have multiple layers of conductive traces, separated by insulating material. They are used in high-density applications requiring complex circuitry, such as computers and telecommunications equipment.

- Flexible circuit boards: These boards are made from flexible materials, allowing them to be bent or folded without damaging the circuitry. They are used in applications where space constraints or flexibility is essential, such as wearable devices and medical equipment.

- Rigid-flex circuit boards: These boards combine rigid and flexible sections, providing both structural support and flexibility. They are used in applications where both rigidity and flexibility are required, such as automotive electronics and aerospace systems.

2. What are the key steps involved in the circuit board assembly process?

Pre-assembly

- Inspecting and preparing components

- Applying solder paste to circuit board pads

- Placing components onto the circuit board

Assembly

- Reflowing or wave soldering to connect components to the circuit board

- Cleaning the circuit board to remove flux and other residues

Inspection and testing

- Visual inspection for defects

- Electrical testing to verify functionality

3. How do you ensure the accuracy and quality of your work?

I follow a rigorous quality control process to ensure the accuracy and quality of my work. This includes:

- Visual inspection: I carefully inspect all components and circuit boards before, during, and after assembly to identify any defects or errors.

- Electrical testing: I perform electrical tests on all completed circuit boards to verify their functionality and ensure they meet specifications.

- Adherence to standards: I strictly follow established industry standards and best practices for circuit board assembly, including IPC-A-610.

- Continuous improvement: I regularly review my processes and seek opportunities to improve efficiency and quality.

4. Describe your experience with different types of soldering techniques?

I am proficient in various soldering techniques commonly used in circuit board assembly, including:

- Hand soldering: Manually soldering components onto the circuit board using a soldering iron and solder.

- Wave soldering: Passing the circuit board over a wave of molten solder to create solder joints.

- Reflow soldering: Heating the circuit board in a controlled oven to melt the solder paste and form solder joints.

- Selective soldering: Using a soldering robot to apply solder to specific areas of the circuit board.

5. What are some common defects you encounter during circuit board assembly and how do you troubleshoot them?

Some common defects I encounter during circuit board assembly include:

- Solder bridges: Excess solder connecting two or more solder pads, causing a short circuit.

- Cold solder joints: Weak or incomplete solder joints due to insufficient heat or solder.

- Component misalignment: Components placed incorrectly on the circuit board.

- Missing components: Components that were not placed or soldered onto the circuit board.

To troubleshoot these defects, I use the following methods:

- Visual inspection: Examining the circuit board under magnification to identify defects.

- Electrical testing: Using a multimeter or other test equipment to verify component functionality and continuity.

- Reworking: If a defect is identified, I carefully remove the solder and component, then reassemble and solder it correctly.

6. How do you stay up-to-date with the latest technologies and trends in circuit board assembly?

To stay up-to-date with the latest technologies and trends in circuit board assembly, I engage in the following activities:

- Attending industry conferences and workshops: Participating in events that showcase new technologies, trends, and best practices.

- Reading industry publications and technical journals: Staying informed about the latest advancements in circuit board assembly through written sources.

- Researching online and networking with other professionals: Utilizing the internet and professional networks to learn about new techniques and solutions.

- Seeking training and certification: Completing training programs and obtaining certifications to enhance my knowledge and skills.

7. What are some of the challenges you have faced in your previous circuit board assembly roles and how did you overcome them?

In my previous circuit board assembly roles, I encountered the following challenges and overcame them in the following ways:

- Meeting tight deadlines: I effectively managed my time and prioritized tasks to deliver projects on schedule, often working overtime to complete urgent orders.

- Resolving complex technical issues: I utilized my problem-solving skills and sought support from colleagues or supervisors to identify the root cause of issues and implement effective solutions.

- Maintaining a high level of accuracy: I established a rigorous quality control process, including visual inspection and electrical testing, to ensure the accuracy and reliability of my work.

- Working in a demanding production environment: I adapted to the fast-paced and often stressful production environment by maintaining focus, prioritizing tasks, and collaborating with team members to achieve production goals.

8. Why are you interested in working for our company?

I am interested in working for your company because:

- Industry reputation: Your company is known for its high standards, commitment to quality, and innovative products.

- Growth opportunities: I believe that your company offers opportunities for professional development and career advancement.

- Product portfolio: I am excited about the prospect of working on your company’s cutting-edge circuit board designs.

- Company culture: I admire your company’s focus on teamwork, quality, and customer satisfaction.

9. What are your salary expectations?

My salary expectations are in line with the industry average for Circuit Board Assemblers with my experience and skills. I am open to discussing a competitive salary package that reflects the value I can bring to your company.

10. When are you available to start?

I am available to start immediately and am flexible with my start date to accommodate your company’s needs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circuit Board Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circuit Board Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Circuit Board Assembler plays a vital role in the manufacturing process of electronic devices and systems. Their key responsibilities encompass a wide range of tasks, including:

1. Assembly and Inspection

Circuit Board Assemblers are responsible for assembling and assembling electronic components onto printed circuit boards (PCBs) in accordance with established procedures and specifications. They carefully place and solder components onto PCBs, ensuring accuracy and precision. Additionally, they may inspect assembled PCBs for any defects or errors using visual and electronic testing equipment.

2. Component Preparation

Prior to assembly, Circuit Board Assemblers prepare components for installation. This involves activities such as straightening leads, trimming excess materials, and organizing components for efficient use. They may also perform lead forming or kitting operations as part of the preparation process.

3. Material Handling

Circuit Board Assemblers handle a variety of materials, including PCBs, components, and tools. They maintain inventory and ensure the availability of necessary materials for assembly operations. Additionally, they may be responsible for packaging and shipping finished products.

4. Equipment Operation

Circuit Board Assemblers operate specialized equipment and tools during the assembly process. This includes soldering irons, pick-and-place machines, and inspection equipment. Proper use and maintenance of equipment are essential for efficient and accurate assembly.

5. Quality Assurance

Circuit Board Assemblers contribute to quality assurance by adhering to established assembly standards and procedures. They inspect their work regularly and may perform quality control checks on finished products. By maintaining high standards, they help ensure the reliability and functionality of electronic devices.

Interview Preparation Tips

Thorough preparation is crucial for acing an interview for a Circuit Board Assembler position. Here are some valuable tips and hacks to help candidates:

1. Research the Company

Research the company’s website, social media pages, and industry news to gain insights into their business operations, culture, and values. This knowledge will enable you to connect your skills and experience with the company’s needs and demonstrate your enthusiasm for the position.

2. Practice Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations. Some key questions to prepare for include:

- Tell us about your experience in circuit board assembly.

- What are your strengths and weaknesses as a Circuit Board Assembler?

- Why are you interested in this position with our company?

3. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key skills and experience required for the position. Tailor your resume and cover letter to highlight how your qualifications meet these requirements. Quantify your accomplishments and provide specific examples to showcase your capabilities.

4. Prepare Questions for the Interviewer

At the end of the interview, you will likely be given the opportunity to ask questions. Prepare thoughtful questions that demonstrate your interest in the position and the company. This is an excellent time to clarify any aspects of the role or company that you are curious about.

5. Dress Professionally

Dress professionally for the interview to make a positive first impression. Neat and appropriate attire shows respect for the interviewer and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Circuit Board Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Circuit Board Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.