Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Circuitry Negative Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Circuitry Negative Inspector so you can tailor your answers to impress potential employers.

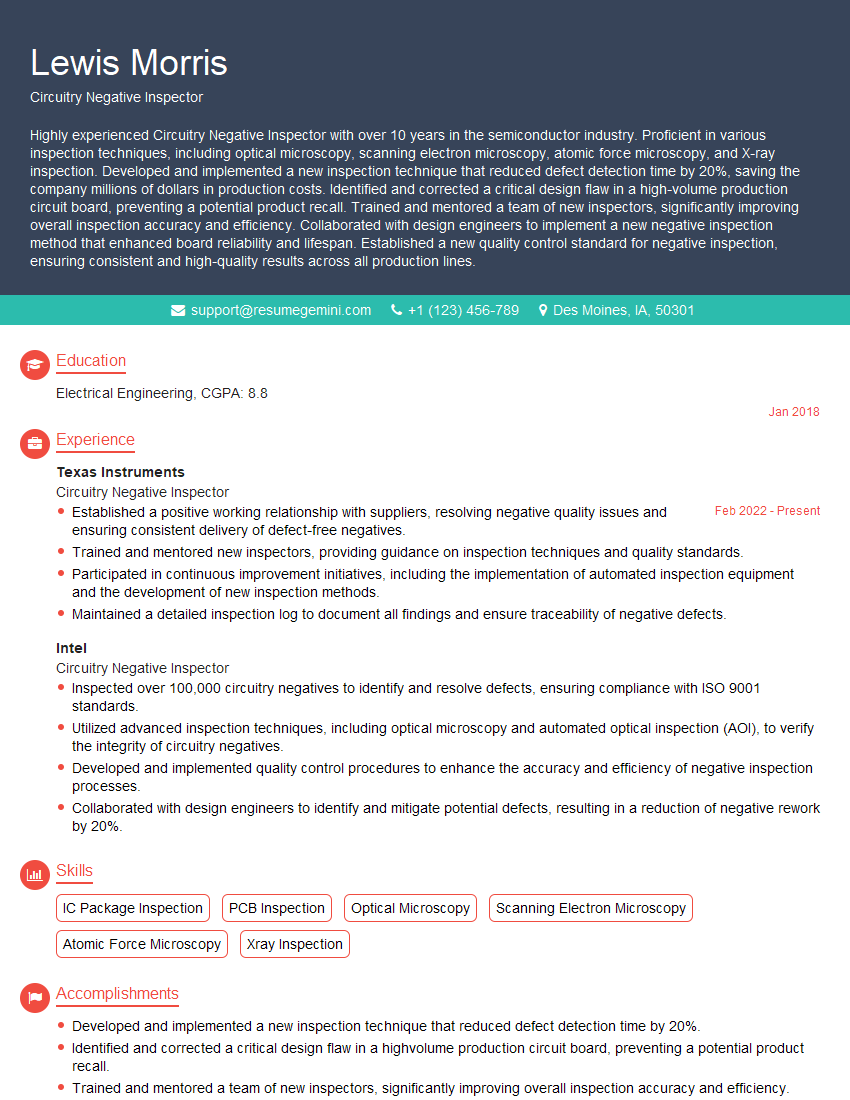

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circuitry Negative Inspector

1. What is the role of a Circuitry Negative Inspector?

The role of a Circuitry Negative Inspector is to inspect circuit boards for any defects or errors. This includes checking for missing or damaged components, solder bridges, and other potential problems. Circuitry Negative Inspectors use a variety of tools and techniques to identify and document defects, and they often work closely with other members of the manufacturing team to ensure that products meet quality standards.

2. What are the most common types of defects that you look for?

Solder defects

- Solder bridges: These are connections between two or more solder pads that are not supposed to be connected.

- Cold solder joints: These are solder joints that are not properly fused together, which can lead to intermittent connections or failures.

- Solder balls: These are small, round solder droplets that can form on the surface of a circuit board.

Component defects

- Missing components: These are components that are not installed on the circuit board, or that are installed incorrectly.

- Damaged components: These are components that have been damaged during the manufacturing process.

- Incorrect components: These are components that are not the correct type or value for the circuit.

3. What are some of the challenges of being a Circuitry Negative Inspector?

- The work can be repetitive and visually demanding.

- Inspectors must be able to work quickly and accurately.

- Inspectors must be able to identify and document defects correctly.

- Inspectors must be able to work independently and as part of a team.

4. What are some of the qualities of a successful Circuitry Negative Inspector?

- Excellent visual acuity and attention to detail.

- Strong knowledge of circuit board manufacturing processes.

- Experience with a variety of inspection tools and techniques.

- Ability to work independently and as part of a team.

- Excellent communication and documentation skills.

5. What is your favorite part of being a Circuitry Negative Inspector?

My favorite part of being a Circuitry Negative Inspector is the challenge of finding defects that other people miss. I enjoy using my skills and knowledge to help ensure that products are manufactured to the highest quality standards.

6. What is the most difficult part of being a Circuitry Negative Inspector?

The most difficult part of being a Circuitry Negative Inspector is the repetitive nature of the work. It can be challenging to stay focused and accurate for long periods of time.

7. What are some of the trends you are seeing in the Circuitry Negative Inspection industry?

- Increased use of automation.

- Increased focus on quality control.

- Greater emphasis on training and certification.

8. What are some of the challenges facing the Circuitry Negative Inspection industry?

- The rising cost of labor.

- The increasing complexity of circuit boards.

- The need for continuous training and development.

9. What are some of the opportunities for growth in the Circuitry Negative Inspection industry?

- The growth of the electronics industry.

- The increasing demand for high-quality products.

- The development of new inspection technologies.

10. What is your career goal?

My career goal is to become a lead Circuitry Negative Inspector. I want to continue to develop my skills and knowledge in the industry, and I want to help my company achieve its quality goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circuitry Negative Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circuitry Negative Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Circuitry Negative Inspectors are responsible for analyzing and identifying defects in printed circuit boards (PCBs). They use various tools and techniques to examine the PCBs for potential issues that could affect their performance or reliability. They play a crucial role in ensuring the quality and functionality of electronic devices.

1. Conduct Visual Inspections

Inspectors visually examine PCBs to detect any physical defects, such as scratches, dents, or missing components. They use high-powered microscopes and specialized equipment to scrutinize the boards for irregularities.

- Check for surface imperfections, solder bridges, and other anomalies.

- Examine component placement, orientation, and alignment.

2. Perform Electrical Tests

Inspectors conduct electrical tests to verify the functionality of the PCBs. They use specialized equipment to measure voltage, current, and resistance to ensure that the boards meet the required electrical specifications.

- Execute continuity tests to detect open circuits or shorts.

- Conduct isolation tests to verify the electrical separation between different sections of the board.

3. Analyze Test Results

Inspectors carefully analyze the results of the visual and electrical tests to identify any potential defects or non-conformities. They use their technical knowledge and experience to determine if the PCBs meet the required standards.

- Interpret test data and identify potential failures.

- Generate reports and communicate findings to management or manufacturing personnel.

4. Maintain Inspection Equipment

Inspectors are responsible for maintaining and calibrating the equipment used for testing and inspecting PCBs. They ensure that the equipment is functioning properly and is up-to-date with the latest technological advancements.

- Perform routine maintenance and calibration on microscopes, electrical testers, and other equipment.

- Troubleshoot and resolve technical issues with inspection equipment.

Interview Tips

Preparing for an interview for a Circuitry Negative Inspector position is crucial for showcasing your skills and experience effectively. Here are a few tips and hacks to help you ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company and the specific role you are applying for. This demonstrates your interest in the organization and the position, and it allows you to tailor your answers to the specific requirements.

2. Practice Your Answers

Prepare answers to common interview questions related to your skills, experience, and motivations. Practice delivering your answers concisely and confidently. Consider using the STAR (Situation, Task, Action, Result) method to structure your responses and provide specific examples.

3. Emphasize Your Attention to Detail

As an inspector, meticulous attention to detail is paramount. Highlight your ability to identify and analyze defects with precision. Provide examples of your experience in detecting even the most minor deviations from specifications.

4. Demonstrate Your Analytical Skills

Inspectors need to be able to interpret test results and identify potential issues. Emphasize your analytical skills and your ability to draw accurate conclusions from data. Explain how you approach problem-solving and troubleshooting.

5. Showcase Your Technical Proficiency

Be prepared to discuss your technical knowledge and experience. Explain your understanding of electrical principles, testing procedures, and inspection equipment. Demonstrate your familiarity with industry standards and regulations.

6. Highlight Your Quality Control Mindset

Inspectors play a vital role in ensuring the quality of electronic devices. Emphasize your commitment to quality control and your understanding of the importance of defect prevention. Explain your approach to minimizing errors and maintaining high standards.

7. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your knowledge of the industry and your eagerness to learn and contribute.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Circuitry Negative Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Circuitry Negative Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.