Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Circular Saw-Edge Fuser interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Circular Saw-Edge Fuser so you can tailor your answers to impress potential employers.

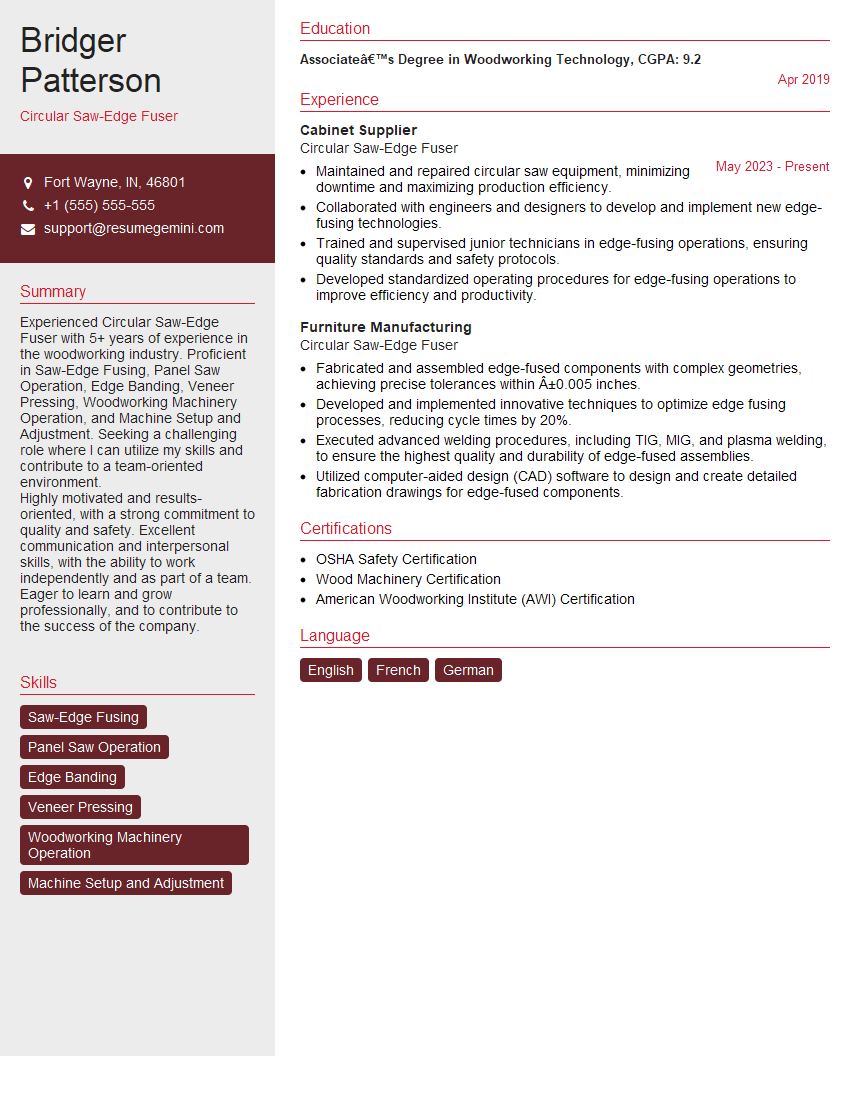

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circular Saw-Edge Fuser

1. Explain in detail about the working principle of Circular Saw-Edge Fuser?

A circular saw-edge fuser is a type of fuser used in laser printers. It uses a heated circular saw blade to fuse toner particles onto paper. The blade is rotated at high speed, and the paper is passed over the blade. The heat from the blade causes the toner particles to melt and bond with the paper. Circular saw-edge fusers are typically used in high-speed printers because they can fuse toner particles at a high rate of speed.

2. What are the advantages of using a Circular Saw-Edge Fuser?

Advantages of using a Circular Saw-Edge Fuser:

- High-speed fusing: Circular saw-edge fusers can fuse toner particles at a high rate of speed, making them ideal for high-speed printers.

- Good print quality: Circular saw-edge fusers can produce high-quality prints with sharp text and images.

- Durable: Circular saw-edge fusers are durable and can withstand the high temperatures and pressures required for fusing toner particles.

3. What are the disadvantages of using a Circular Saw-Edge Fuser?

Disadvantages of using a Circular Saw-Edge Fuser:

- High cost: Circular saw-edge fusers are more expensive than other types of fusers.

- Complex maintenance: Circular saw-edge fusers require more maintenance than other types of fusers.

- Safety concerns: Circular saw-edge fusers can be dangerous if they are not properly maintained.

4. What are the key factors to consider when selecting a Circular Saw-Edge Fuser?

Factors to consider when selecting a Circular Saw-Edge Fuser:

- Print speed: The print speed of the printer.

- Print quality: The desired print quality.

- Cost: The budget for the fuser.

- Maintenance requirements: The maintenance requirements of the fuser.

- Safety features: The safety features of the fuser.

5. How do you troubleshoot a Circular Saw-Edge Fuser?

Troubleshooting a Circular Saw-Edge Fuser:

- Check the power supply to the fuser.

- Check the temperature of the fuser.

- Check the speed of the fuser blade.

- Check the tension of the fuser belt.

- Check the condition of the fuser blade.

- Check the condition of the fuser roller.

6. What are the safety precautions that must be taken when working with a Circular Saw-Edge Fuser?

Safety precautions when working with a Circular Saw-Edge Fuser:

- Always wear safety glasses when working with a circular saw-edge fuser.

- Never touch the fuser blade.

- Never operate the fuser without the cover in place.

- Keep the fuser area clean and free of debris.

- Follow all manufacturer’s instructions for operating and maintaining the fuser.

7. What are the common problems associated with Circular Saw-Edge Fusers?

Common problems associated with Circular Saw-Edge Fusers:

- Paper jams

- Wrinkled paper

- Faded prints

- Ghosting

- Overheating

8. How do you maintain a Circular Saw-Edge Fuser?

Maintaining a Circular Saw-Edge Fuser:

- Clean the fuser blade regularly.

- Inspect the fuser roller for wear and tear.

- Check the tension of the fuser belt.

- Lubricate the fuser bearings.

- Follow all manufacturer’s instructions for maintaining the fuser.

9. What are the different types of Circular Saw-Edge Fusers available?

Different types of Circular Saw-Edge Fusers:

- Single-pass fusers

- Multi-pass fusers

- High-speed fusers

- Low-speed fusers

10. What are the future trends in Circular Saw-Edge Fuser technology?

Future trends in Circular Saw-Edge Fuser technology:

- Increased use of high-speed fusers

- Development of more energy-efficient fusers

- Development of more compact fusers

- Development of fusers that can handle a wider range of paper types

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circular Saw-Edge Fuser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circular Saw-Edge Fuser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Circular Saw-Edge Fuser is responsible for operating and maintaining a circular saw and edge fuser to cut, join, and finish various materials. Their primary duties include:

1. Saw Operation

Set up and operate a circular saw to cut panels, boards, and other materials according to specifications.

- Adjust saw settings for different materials and cutting requirements.

- Ensure proper blade maintenance and replacement.

2. Edge Fusing

Operate an edge fuser to join and seal edges of materials.

- Select and install appropriate edge banding materials.

- Adjust fuser settings for optimal bonding and finish.

3. Material Handling

Load, unload, and transport materials throughout the production process.

- Operate forklifts or other material handling equipment as needed.

- Maintain a clean and organized work area.

4. Quality Control

Inspect finished products to ensure they meet quality standards.

- Identify and rectify defects in cutting or edge fusing.

- Follow established quality control procedures.

Interview Tips

To prepare effectively for an interview for a Circular Saw-Edge Fuser position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific responsibilities and requirements of the Circular Saw-Edge Fuser role within the organization.

2. Practice your Skills

If possible, practice operating a circular saw and edge fuser before the interview. Demonstrate your proficiency in handling the equipment and producing high-quality results.

3. Highlight your Experience

Emphasize your experience in cutting, joining, and finishing materials using circular saws and edge fusers. Provide specific examples of successful projects you have completed.

4. Showcase your Quality Standards

Stress your commitment to quality and attention to detail. Explain your process for ensuring that finished products meet or exceed customer expectations.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows your engagement and eagerness to learn more.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Circular Saw-Edge Fuser, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Circular Saw-Edge Fuser positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.