Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

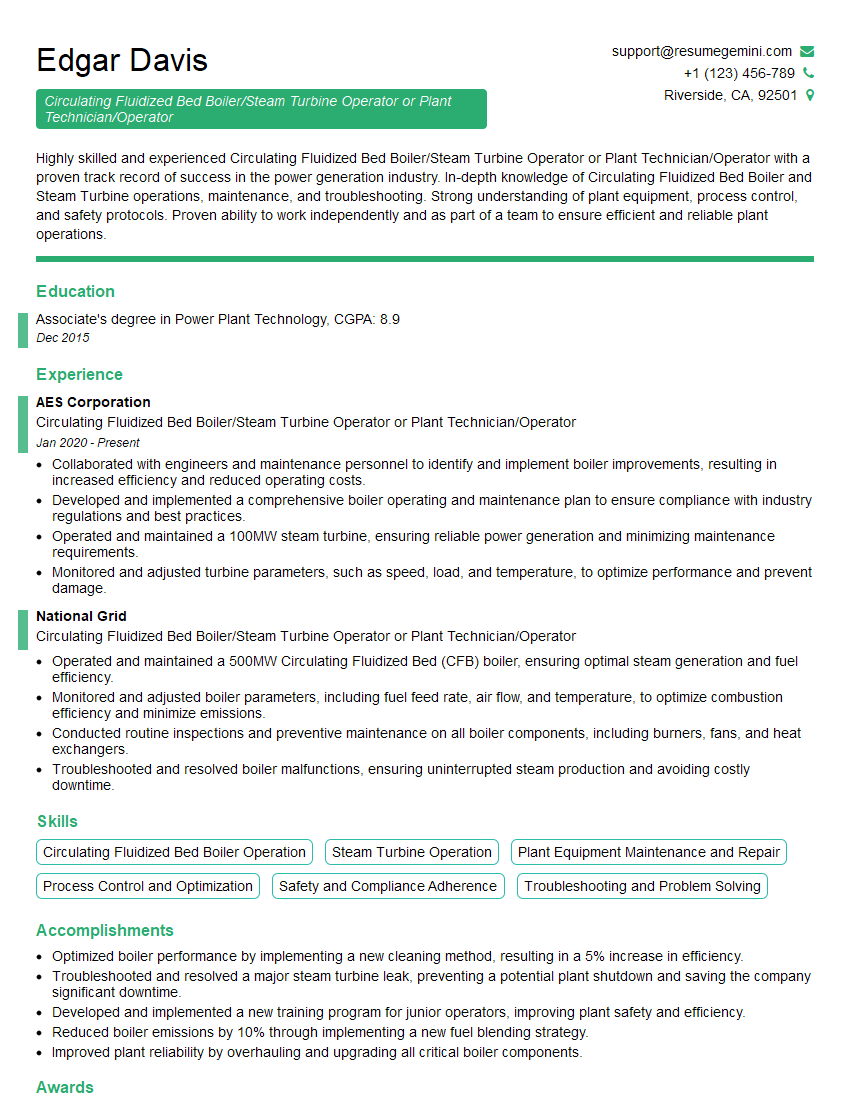

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator

1. Explain the working principle of a Circulating Fluidized Bed (CFB) boiler?

In a CFB boiler, a mixture of crushed coal and limestone is suspended in a fluidized bed of air. The air is introduced from the bottom of the bed, causing the particles to become suspended and circulate within the bed.

- The combustion process takes place within the bed, with the heat being transferred to the surrounding tubes.

- The limestone reacts with the sulfur in the coal, forming calcium sulfate, which is removed as a solid waste product.

2. Describe the key components of a steam turbine generator system and explain their functions?

Turbine

- The turbine is the heart of the system, converting the energy of the steam into mechanical energy.

- The turbine consists of a series of rotating blades mounted on a shaft, and a series of stationary blades.

- As the steam passes through the blades, it causes them to rotate, which in turn drives the shaft.

Generator

- The generator is mounted on the same shaft as the turbine, and it converts the mechanical energy of the shaft into electrical energy.

- The generator consists of a series of windings, which are connected to an external electrical circuit.

- As the shaft rotates, the windings cut through the magnetic field, inducing an electrical current in the windings.

3. What are the key safety considerations when operating a CFB boiler or steam turbine?

- Ensure that all equipment is properly maintained and inspected regularly.

- Follow all safety procedures and protocols.

- Be aware of the potential hazards associated with the operation of the equipment.

- Take all necessary precautions to prevent accidents.

4. How do you troubleshoot common problems that may arise in the operation of a CFB boiler or steam turbine?

- Become familiar with the equipment and its operation.

- Review the equipment’s maintenance and repair manuals.

- Develop a troubleshooting plan.

- Use diagnostic tools to identify the source of the problem.

- Take corrective action to resolve the problem.

5. What are the environmental regulations that apply to the operation of a CFB boiler or steam turbine, and how do you ensure compliance?

- Review the environmental regulations that apply to the operation of the equipment.

- Develop a plan to ensure compliance with the regulations.

- Monitor the equipment’s operation to ensure that it is in compliance with the regulations.

- Take corrective action if the equipment is not in compliance with the regulations.

6. Describe the role of instrumentation and control systems in the operation of a CFB boiler or steam turbine?

- Instrumentation and control systems are used to monitor and control the operation of the equipment.

- Instrumentation systems measure the parameters of the equipment, such as pressure, temperature, and flow rate.

- Control systems use the information from the instrumentation systems to adjust the operation of the equipment.

7. What is the importance of maintaining proper water chemistry in a steam turbine system?

- Maintaining proper water chemistry is important to prevent corrosion and scaling in the steam turbine system.

- Corrosion can damage the turbine blades and other components, leading to reduced efficiency and increased maintenance costs.

- Scaling can also reduce the efficiency of the turbine by reducing the flow of steam through the blades.

8. What are the different types of steam turbine governors, and how do they work?

Mechanical governors

- Mechanical governors use a mechanical linkage to control the flow of steam to the turbine.

- As the turbine speed increases, the governor moves to reduce the flow of steam, and as the turbine speed decreases, the governor moves to increase the flow of steam.

Hydraulic governors

- Hydraulic governors use a hydraulic system to control the flow of steam to the turbine.

- As the turbine speed increases, the governor uses hydraulic pressure to reduce the flow of steam, and as the turbine speed decreases, the governor uses hydraulic pressure to increase the flow of steam.

Electronic governors

- Electronic governors use an electronic control system to control the flow of steam to the turbine.

- As the turbine speed increases, the governor sends an electronic signal to reduce the flow of steam, and as the turbine speed decreases, the governor sends an electronic signal to increase the flow of steam.

9. What are the advantages and disadvantages of using a CFB boiler compared to a conventional pulverized coal boiler?

Advantages

- CFB boilers can burn a wider range of fuels, including low-grade fuels and biomass.

- CFB boilers have lower emissions of nitrogen oxides and sulfur oxides than conventional pulverized coal boilers.

- CFB boilers are more efficient than conventional pulverized coal boilers.

Disadvantages

- CFB boilers are more expensive to build than conventional pulverized coal boilers.

- CFB boilers require more maintenance than conventional pulverized coal boilers.

- CFB boilers are not as flexible as conventional pulverized coal boilers in terms of load following.

10. Describe your experience with troubleshooting and resolving problems in a power plant environment?

- In my previous role as a Power Plant Operator, I was responsible for troubleshooting and resolving a variety of problems, including equipment failures, process upsets, and environmental compliance issues.

- I have experience using a variety of diagnostic tools and techniques to identify and resolve problems quickly and efficiently.

- I am also familiar with the power plant’s operating procedures and safety protocols, and I always follow these procedures when troubleshooting and resolving problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Circulating Fluidized Bed Boiler/Steam Turbine Operators or Plant Technicians/Operators play a vital role in the efficient and safe operation of power plants. Here are key responsibilities associated with these positions:

1. Boiler and Turbine Operation

Operate and monitor circulating fluidized bed boilers and steam turbines, ensuring optimal performance and reliability.

- Start, stop, and regulate boilers and turbines according to established procedures.

- Monitor and control boiler and turbine parameters, such as temperature, pressure, fuel flow, and emissions.

2. Maintenance and Inspection

Perform routine maintenance, inspections, and troubleshooting for boilers, turbines, and associated equipment.

- Conduct preventive maintenance tasks, including lubrication, cleaning, and adjustments.

- Identify and troubleshoot equipment malfunctions, implementing corrective actions to restore operations.

3. Safety and Compliance

Uphold safety regulations and industry standards to ensure the safe and efficient operation of the plant.

- Adhere to established safety protocols, including lockout/tagout procedures.

- Monitor and maintain environmental compliance, adhering to air and water quality regulations.

4. Communication and Teamwork

Effectively communicate with colleagues, supervisors, and external stakeholders.

- Provide regular updates on boiler and turbine operations to management and engineering teams.

- Collaborate with maintenance personnel and vendors to ensure seamless equipment repairs and upgrades.

Interview Preparation Tips

To ace an interview for a Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator position, consider the following preparation tips:

1. Research the Company and Position

Thoroughly research the company’s operations, industry standing, and the specific role you are applying for. This demonstrates your interest and preparation.

- Visit the company’s website, read industry publications, and consult with professionals in the field.

2. Review Key Job Responsibilities

Make sure you have a comprehensive understanding of the job responsibilities outlined in the position description. Highlight your relevant skills and experience.

- Prepare examples of your past work that demonstrate your abilities in boiler and turbine operation, maintenance, and troubleshooting.

3. Emphasize Safety and Compliance

The power industry places a high priority on safety. Showcase your commitment to safety and compliance by discussing your knowledge of industry regulations and best practices.

- Provide examples of your involvement in safety initiatives or compliance audits.

4. Highlight Communication and Teamwork Skills

Interviewers seek candidates who can effectively communicate and collaborate. Provide examples that illustrate your ability to work well with others and convey technical information clearly.

- Describe instances where you successfully resolved technical issues in a collaborative setting.

5. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your engagement and interest in the role. It also provides an opportunity to clarify aspects of the job or company.

- Ask about the plant’s specific operating practices, environmental initiatives, or future projects.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Circulating Fluidized Bed Boiler/Steam Turbine Operator or Plant Technician/Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.