Feeling lost in a sea of interview questions? Landed that dream interview for Clamp Carrier Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Clamp Carrier Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

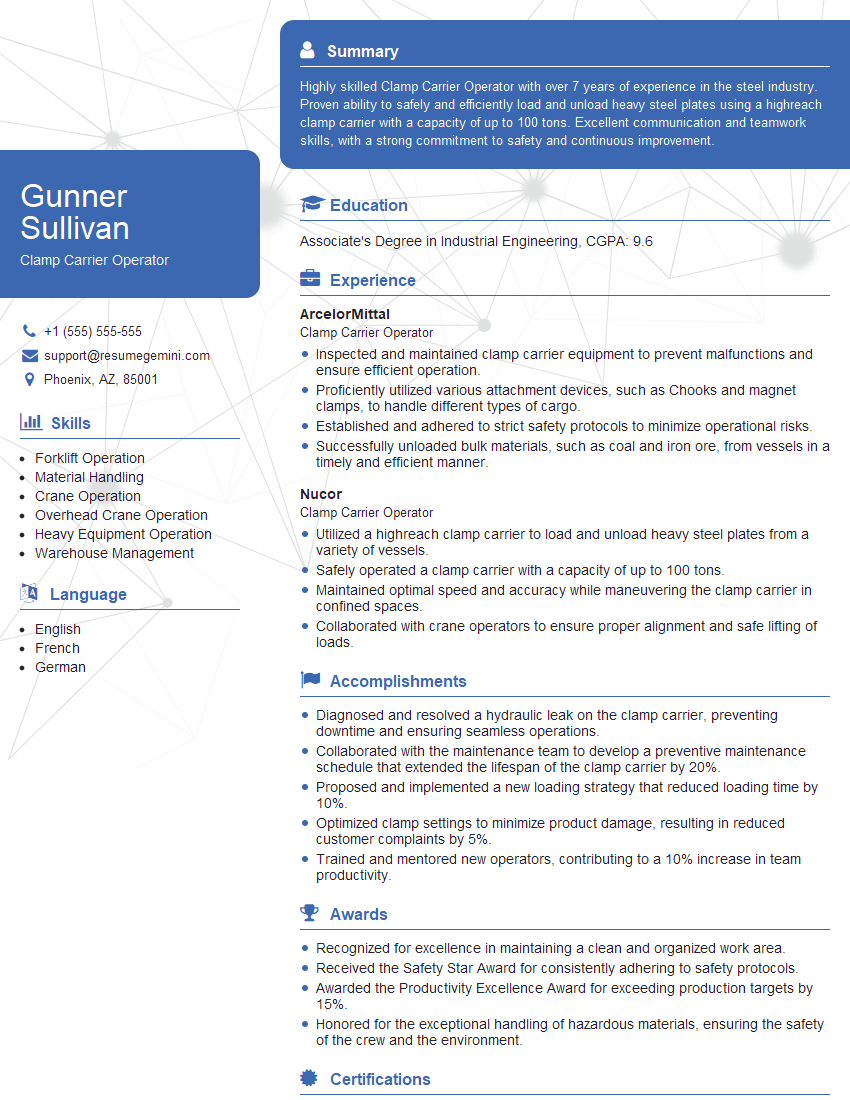

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clamp Carrier Operator

1. What are the main responsibilities of a Clamp Carrier Operator?

- Operate a clamp carrier to transport materials and products within a warehouse or manufacturing facility.

- Load and unload materials and products from trucks and trailers using the clamp carrier’s forks or clamps.

- Identify and follow proper stacking procedures to ensure the safe and efficient storage of materials.

- Maintain a clean and organized work area, including the clamp carrier and surrounding areas.

- Inspect and report any damage or mechanical issues to the clamp carrier or materials being handled.

2. What are the key safety precautions that must be followed when operating a clamp carrier?

Safe Operation

- Wear appropriate personal protective equipment (PPE), such as hard hat, safety shoes, and high-visibility vest.

- Inspect the clamp carrier before each use, ensuring that it is in good working condition.

- Operate the clamp carrier at a safe speed and maintain a safe distance from other equipment and personnel.

- Be aware of the surroundings and potential hazards, such as overhead obstacles and slippery surfaces.

Material Handling

- Ensure that the load is properly balanced and secured before lifting or transporting.

- Avoid overloading the clamp carrier and follow the manufacturer’s weight capacity guidelines.

- Use caution when transporting materials on ramps or uneven surfaces.

- Never leave the clamp carrier unattended with the forks or clamps raised.

3. Describe the different types of clamps used on clamp carriers and their specific applications.

- Single-arm clamp: Used for handling cylindrical objects, such as pipes and drums.

- Double-arm clamp: Used for handling rectangular objects, such as pallets and crates.

- Forklift attachment clamp: Used to convert a forklift into a clamp carrier, allowing for the handling of materials without pallets.

- Side-shift clamp: Used to laterally move the load while it is being transported.

- Rotating clamp: Used to rotate the load 360 degrees while it is being transported.

4. How do you determine the center of gravity of an unbalanced load?

- Estimate the weight and distribution of the load.

- Use a plumb bob or level to find the vertical center of the load.

- Measure the distance from the vertical center to the edge of the load in different directions.

- Multiply the distance by the corresponding weight to calculate the moment for each direction.

- The center of gravity is located where the moments are equal and opposite.

5. Explain the importance of preventive maintenance for clamp carriers and how it contributes to operational efficiency.

- Increased uptime: Regular maintenance helps identify and address potential issues before they cause breakdowns, ensuring that the clamp carrier is available for operation when needed.

- Improved performance: Proper maintenance ensures that the clamp carrier is operating at its optimal performance, resulting in efficient material handling and increased productivity.

- Reduced maintenance costs: Preventive maintenance helps detect and resolve minor issues before they escalate into more costly repairs, saving money in the long run.

- Enhanced safety: Regular maintenance ensures that the clamp carrier is safe to operate, minimizing the risk of accidents and injuries.

- Extended lifespan: Proper maintenance prolongs the life of the clamp carrier, maximizing its return on investment.

6. Describe the process of troubleshooting electrical problems on a clamp carrier.

- Identify the symptoms of the problem, such as intermittent operation, power loss, or warning lights.

- Check the battery connections, fuses, and circuit breakers for loose or damaged parts.

- Use a multimeter to test the voltage and continuity of electrical components, such as wires, switches, and solenoids.

- Inspect electrical connectors for corrosion or damage.

- Follow the manufacturer’s troubleshooting guide for specific instructions and diagnostic steps.

7. How do you safely lift and transport a load that is heavier than the clamp carrier’s rated capacity?

- Never attempt to lift a load that exceeds the rated capacity of the clamp carrier.

- If a load must be lifted and transported that is heavier than the rated capacity, use a different piece of equipment, such as a forklift or crane.

- If no other equipment is available, obtain assistance from other personnel to help lift and transport the load manually.

8. What are the common causes of clamp carrier accidents and how can they be prevented?

Common Causes

- Overloading

- Unstable loads

- Improper operation

- Lack of maintenance

- Operator fatigue

Preventive Measures

- Follow the manufacturer’s guidelines and never overload the clamp carrier.

- Inspect loads carefully and ensure they are stable before lifting.

- Receive proper training on the safe operation of the clamp carrier.

- Perform regular maintenance to keep the clamp carrier in good working condition.

- Take breaks throughout the day to avoid fatigue and maintain alertness.

9. Describe the role of the Clamp Carrier Operator in ensuring the accuracy and efficiency of the inventory management system.

- Accurate documentation: Record all material movements, including the type and quantity of materials, source and destination locations, and time of movement.

- Real-time updates: Enter data into the inventory management system as soon as possible to ensure that inventory records are up-to-date.

- Verification of inventory: Cross-check physical inventory counts with the inventory management system to identify any discrepancies.

- Communication with other departments: Share inventory information with other departments, such as purchasing and production, to facilitate efficient material planning.

10. How do you handle working in a fast-paced warehouse environment with high production demands?

- Prioritize tasks: Identify the most important tasks and focus on completing them first.

- Organize the work area: Keep the clamp carrier and surrounding area organized to minimize wasted time searching for materials or tools.

- Communicate effectively: Maintain clear communication with other operators and supervisors to ensure smooth coordination and avoid delays.

- Work efficiently: Use proper lifting techniques and operate the clamp carrier smoothly to maximize productivity.

- Take breaks: Regular breaks help maintain focus and prevent fatigue, which can lead to errors and reduced efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clamp Carrier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clamp Carrier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clamp Carrier Operators are responsible for transporting and handling materials within a manufacturing or warehouse setting. They use specialized equipment to move large objects, such as steel coils, lumber, and heavy machinery. Key responsibilities of a Clamp Carrier Operator include:

1. Material Handling

Operators use clamp carriers to lift, move, and stack materials. They must be able to safely operate the equipment and manoeuvre it in tight spaces.

- Lifting and transporting materials using clamp carriers

- Positioning materials accurately and safely

- Ensuring that materials are loaded and secured properly

2. Equipment Maintenance

Operators perform basic maintenance on clamp carriers, ensuring that the equipment is in good working condition. They also report any issues to supervisors.

- Performing daily inspections and routine maintenance tasks

- Lubricating and cleaning equipment

- Identifying and reporting any equipment malfunctions

3. Safety and Compliance

Operators are responsible for maintaining a safe work environment and following all safety protocols. They also ensure that materials are handled in a way that minimizes risks.

- Adhering to safety guidelines and regulations

- Wearing appropriate safety gear

- Inspecting equipment for safety hazards

4. Teamwork and Communication

Clamp Carrier Operators often work as part of a team with other operators, supervisors, and warehouse personnel. Effective communication and teamwork are essential for ensuring smooth operations.

- Collaborating with colleagues to ensure efficient material handling

- Communicating effectively with supervisors and other team members

- Following instructions and adhering to established work procedures

Interview Tips

To prepare for an interview for a Clamp Carrier Operator position, consider the following tips:

1. Research the Company

Learn about the company’s industry, size, and products. This will help you understand the context of the role and demonstrate your interest in the company.

2. Practice Common Interview Questions

Prepare for standard interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Consider your answers and practice delivering them confidently.

- Example Outline:

- Start with a brief introduction of yourself and your relevant experience.

- Highlight your skills and qualifications that align with the job requirements.

- Explain your interest in the company and the specific role.

- End with a strong statement expressing your enthusiasm and confidence.

3. Emphasize Safety

Safety is paramount in this role. Highlight your understanding of safety regulations and your commitment to maintaining a safe work environment.

4. Demonstrate Your Technical Skills

If possible, provide examples of your experience operating clamp carriers or similar equipment. This will demonstrate your technical proficiency.

5. Showcase Your Teamwork Abilities

Clamp Carrier Operators often work in teams. Emphasize your communication skills and your ability to collaborate effectively with others.

Next Step:

Now that you’re armed with the knowledge of Clamp Carrier Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Clamp Carrier Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini