Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clamp Jig Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

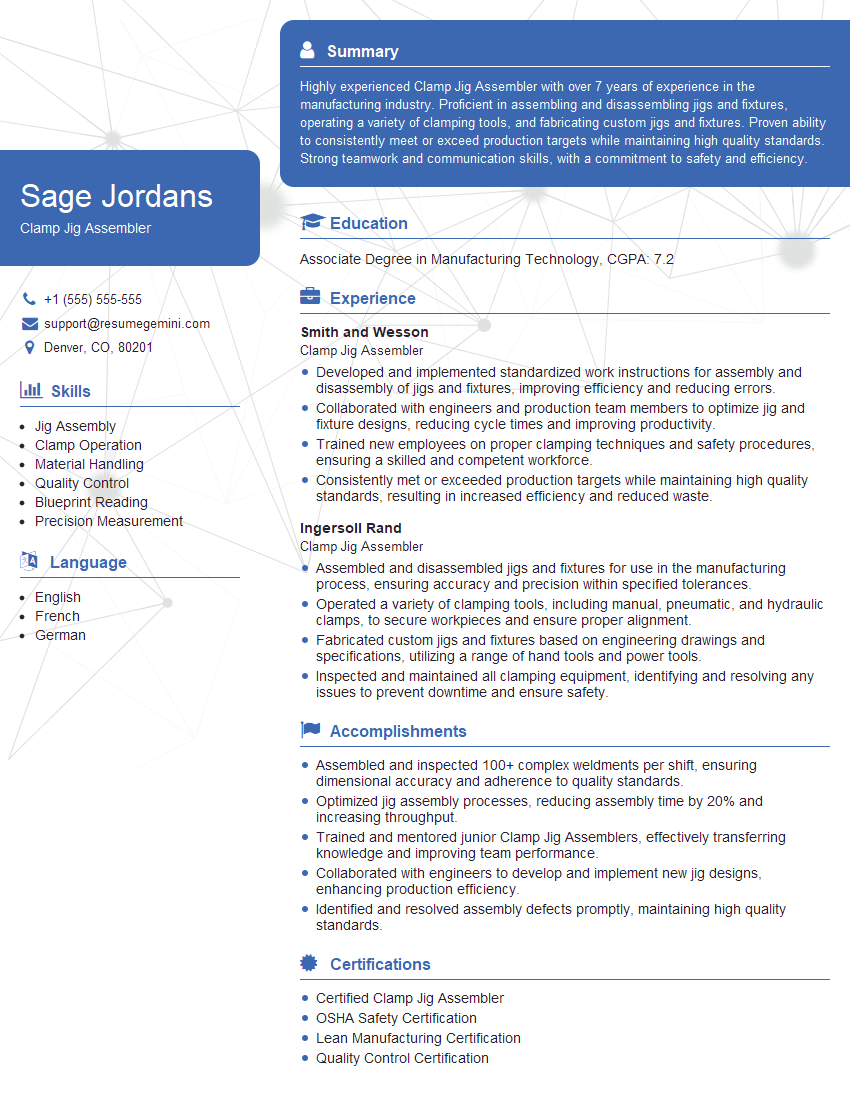

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clamp Jig Assembler

1. What are the primary responsibilities of a Clamp Jig Assembler?

As a Clamp Jig Assembler, I am responsible for the following tasks:

- Assembling and maintaining clamp jigs

- Inspecting jigs for defects and repairs

- Setting up and operating jigs on production lines

- Ensuring jigs meet quality standards

- Troubleshoot and resolve issues with jigs

2. What skills and experience are essential for a Clamp Jig Assembler?

- Proficient in using hand and power tools

- Knowledge of blueprint reading and mechanical drawings

- Ability to work independently and as part of a team

- Strong attention to detail and a commitment to quality

- Experience in a manufacturing or assembly environment

3. What are the different types of clamp jigs used in manufacturing?

- Vertical jigs: Used to hold workpieces vertically for drilling, reaming, and tapping operations

- Horizontal jigs: Used to hold workpieces horizontally for milling, grinding, and shaping operations

- Indexing jigs: Used to hold workpieces in multiple positions for machining operations

- Composite jigs: Used to hold multiple workpieces or components in a single setup

- Specialty jigs: Designed for specific applications, such as welding or assembly

4. How do you ensure that clamp jigs meet quality standards?

I follow a comprehensive quality control process that includes:

- Inspecting incoming materials for defects

- Checking dimensions and tolerances throughout the assembly process

- Testing jigs to ensure they meet performance specifications

- Documenting all inspections and test results

- Taking corrective action when necessary

5. What are some common problems that you have encountered with clamp jigs?

- Misalignment of components

- Excessive wear and tear

- Damage to tooling

- Faulty clamps or fasteners

- Inaccurate machining or grinding

6. How do you troubleshoot and resolve issues with clamp jigs?

- Identify the root cause of the problem

- Develop and implement a solution

- Test the solution to ensure it is effective

- Document the solution for future reference

- Make recommendations for preventive maintenance

7. What are the key factors to consider when designing a clamp jig?

- The purpose of the jig

- The workpiece to be held

- The machining operations to be performed

- The accuracy and precision required

- The materials and components to be used

8. How do you keep up with the latest advancements in clamp jig technology?

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Consulting with industry experts

- Participating in online forums and discussion groups

- Taking advantage of training and development opportunities

9. What are your strengths as a Clamp Jig Assembler?

- Strong attention to detail

- Exceptional troubleshooting skills

- Proficient in using hand and power tools

- Ability to work independently and as part of a team

- Committed to quality and continuous improvement

10. What are your weaknesses as a Clamp Jig Assembler?

- Sometimes I can be too perfectionistic and spend too much time on details

- I am always looking for ways to improve my skills and knowledge, which can sometimes lead to me taking on too much

- I am not always the most patient person, especially when things are not going smoothly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clamp Jig Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clamp Jig Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clamp Jig Assemblers are responsible for assembling and maintaining clamp jigs, which are devices used to hold workpieces in place during machining or assembly operations. They work closely with engineers and other technicians to ensure that the jigs are properly designed and constructed.

1. Assemble and maintain clamp jigs

Clamp Jig Assemblers typically work in a manufacturing environment, where they are responsible for assembling and maintaining clamp jigs. This involves following blueprints and specifications to ensure that the jigs are built to the correct dimensions and tolerances. They also need to be able to troubleshoot and repair any problems that may arise with the jigs.

2. Inspect and test clamp jigs

Once the clamp jigs are assembled, Clamp Jig Assemblers need to inspect and test them to ensure that they are functioning properly. This involves checking the dimensions and tolerances of the jigs, as well as making sure that they are able to hold the workpieces securely in place. They also need to be able to identify and correct any defects that may be present in the jigs.

3. Maintain and repair clamp jigs

Over time, clamp jigs can become worn or damaged, so Clamp Jig Assemblers need to be able to maintain and repair them. This involves replacing worn or damaged parts, as well as making any necessary adjustments to ensure that the jigs continue to function properly. They also need to be able to troubleshoot and repair any problems that may arise with the jigs.

4. Work with engineers and other technicians

Clamp Jig Assemblers often work with engineers and other technicians to ensure that the clamp jigs are properly designed and constructed. They may also be involved in the development and testing of new jigs. They need to be able to communicate effectively with engineers and other technicians, and to understand their requirements.

Interview Tips

If you are preparing for an interview for a Clamp Jig Assembler position, there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can find this information on the company’s website, or by talking to people who work there.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Clamp Jig Assembler. Be prepared to talk about your skills and experience, and to provide examples of your work. You should also be able to discuss your experience with different types of clamp jigs, and your ability to troubleshoot and repair problems.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

5. Be confident and enthusiastic

Confidence and enthusiasm are key to a successful interview. Believe in yourself and your abilities, and let the interviewer know that you are excited about the opportunity to work for their company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Clamp Jig Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Clamp Jig Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.