Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clamp Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

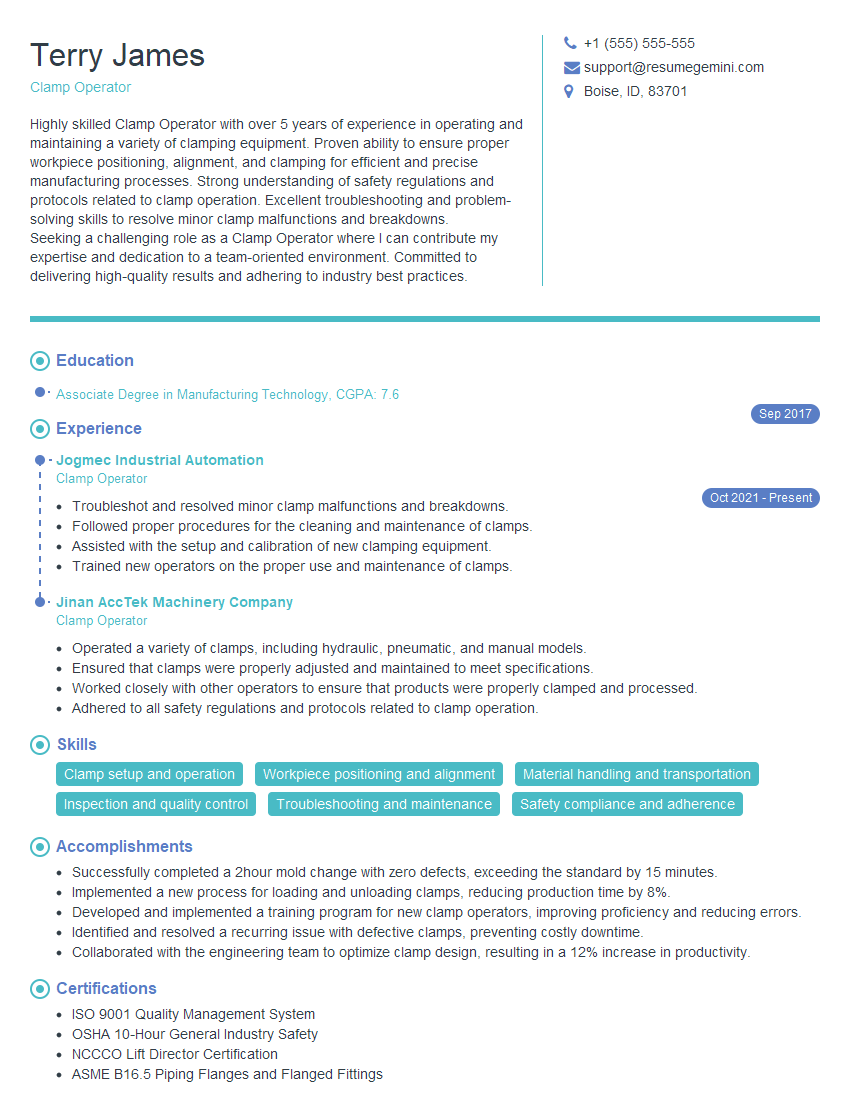

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clamp Operator

1. Explain the principle behind the operation of a clamping machine?

The clamping machine operates on the principle of applying controlled force to hold and secure workpieces during machining or other processes by converting hydraulic or pneumatic pressure into mechanical force.

2. Describe the different types of clamping systems used in manufacturing?

Mechanical Clamping

- Manual Clamping: Uses screws, levers, or wedges to apply force.

- Hydraulic Clamping: Uses hydraulic pressure to generate clamping force.

- Pneumatic Clamping: Uses compressed air to generate clamping force.

Magnetic Clamping

- Permanent Magnet Clamping: Uses permanent magnets to hold ferromagnetic workpieces.

- Electromagnetic Clamping: Uses electromagnets to hold ferromagnetic workpieces.

Vacuum Clamping

- Uses vacuum to hold non-porous workpieces.

3. What are the key factors to consider when selecting a clamping system?

- Size and shape of the workpiece

- Clamping force required

- Accuracy and repeatability required

- Availability of power and resources (e.g., hydraulic, pneumatic, or electrical)

- Cost and maintenance requirements

4. Explain the importance of proper tool and fixture alignment in clamping operations?

Proper tool and fixture alignment ensures that the workpiece is held securely and accurately, preventing movement or deformation during machining. This leads to improved part quality, reduced scrap, and increased productivity.

5. Describe the safety precautions to be taken while operating a clamping machine?

- Wear appropriate safety gear, including gloves, eye protection, and ear protection.

- Ensure that the clamping machine is properly maintained and calibrated.

- Use the correct clamping force for the workpiece and operation.

- Never place hands or fingers near the clamping area while the machine is in operation.

- Follow manufacturer’s instructions and safety protocols.

6. Explain the role of sensors and automation in modern clamping systems?

- Sensors can monitor clamping force, workpiece position, and other parameters, providing real-time feedback for process control and safety.

- Automation allows for the integration of clamping systems with other manufacturing processes, reducing labor requirements and increasing efficiency.

7. Describe the maintenance and troubleshooting procedures for clamping machines?

- Regular cleaning and lubrication

- Checking and adjusting clamping force

- Inspecting and replacing worn components

- Troubleshooting common problems, such as leaks, insufficient clamping force, or misalignment

8. Discuss the emerging trends in clamping technology?

- Advanced sensing and monitoring systems

- Increased use of automated and robotic clamping

- Development of new materials and clamping methods for lightweight and complex workpieces

9. How do you stay updated on the latest advancements in clamping technology?

- Attending industry conferences and exhibitions

- Reading technical journals and articles

- Engaging with industry experts and vendors

- Participating in online forums and discussion groups

10. Give an example of a complex or challenging clamping application you have worked on?

(Provide a specific example, highlighting the challenges encountered and the solutions implemented.)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clamp Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clamp Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clamp Operators play a vital role in manufacturing processes, ensuring proper positioning and securing of materials during assembly and fabrication. Their key responsibilities include:

1. Material Handling and Preparation

A Clamp Operator is responsible for preparing and handling various materials, such as metal sheets, plastic parts, or wood components, before they undergo processing.

- Loading and unloading heavy materials using forklifts or cranes

- Positioning and aligning materials onto the worktable or machine

2. Clamp Operation

Operating the clamps is a crucial aspect of this role. The operator adjusts, secures, and tightly holds the materials in place.

- Selecting appropriate clamps for the specific materials and project requirements

- Applying the appropriate force and pressure to secure materials without damaging them

- Monitoring and adjusting clamps throughout the process

3. Machine Operation and Monitoring

In some cases, Clamp Operators may operate and monitor machines, such as hydraulic presses or welding equipment.

- Setting up and operating machines according to specifications

- Monitoring the machine’s performance and making necessary adjustments

- Ensuring that the machine is functioning safely and efficiently

4. Quality Control and Inspection

Clamp Operators are often responsible for ensuring the quality of the final product.

- Inspecting materials and components for defects or inconsistencies

- Checking the accuracy and precision of the clamping process

- Maintaining records and documentation related to quality control

Interview Tips

Preparing for an interview for a Clamp Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific position you’re applying for. This will give you a better understanding of the company’s culture, values, and expectations for the role.

- Visit the company’s website and LinkedIn page

- Read industry-related articles and news

- Prepare questions to ask the interviewer about the company and position

2. Highlight Your Technical Skills

Emphasize your technical knowledge and experience related to clamping operations. Be prepared to discuss your expertise in:

- Material handling and preparation

- Clamp selection and operation

- Machine operation and monitoring

- Quality control and inspection

3. Showcase Your Soft Skills

In addition to technical skills, employers also value soft skills such as communication, teamwork, and problem-solving.

- Provide examples of how you have effectively communicated with colleagues and supervisors

- Describe your experiences working in a team environment

- Share how you have identified and resolved problems in a manufacturing setting

4. Practice Your Answers

Prepare and practice your answers to common interview questions. This will help you feel more confident and articulate during the interview.

- Review the key job responsibilities and identify questions that might be asked

- Practice answering questions using the STAR method (Situation, Task, Action, Result)

- Seek feedback from a friend, family member, or career counselor on your answers

5. Dress Professionally and Arrive On Time

Make a positive first impression by dressing professionally and arriving at the interview on time. This demonstrates your respect for the interviewer and the company.

- Choose clothing that is appropriate for an industrial setting

- Be punctual and allow yourself plenty of time to find the interview location

- Bring a portfolio or examples of your work to showcase your skills

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clamp Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.