Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clamshell Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clamshell Engineer so you can tailor your answers to impress potential employers.

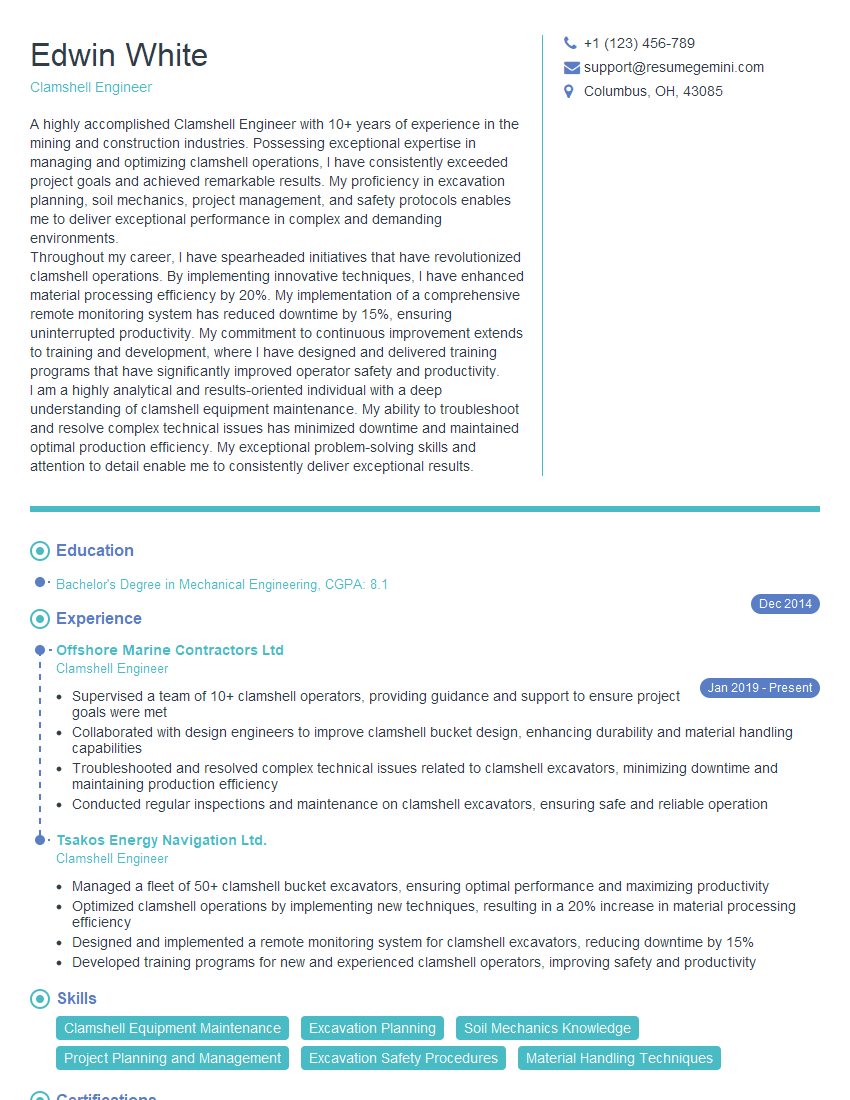

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clamshell Engineer

1. What are the key components of a clamshell bucket?

- Bucket body

- Clamshell jaws

- Hydraulic cylinders

- Hinges

- Teeth

2. Describe the different types of clamshell buckets and their applications.

Mechanical Clamshell Buckets

- Use ropes and sheaves to open and close the jaws

- Suitable for general purpose excavation and dredging

Hydraulic Clamshell Buckets

- Use hydraulic cylinders to open and close the jaws

- Provide greater power and control

- Used in heavy-duty applications such as underwater excavation and demolition

3. What are the factors that affect the efficiency of a clamshell bucket?

- Bucket size and shape

- Material properties

- Digging depth

- Hydraulic system performance

- Operator skill

4. How do you troubleshoot a clamshell bucket that is not opening or closing properly?

- Check hydraulic pressure and flow

- Inspect hydraulic cylinders and hoses for leaks or damage

- Examine hinges and teeth for wear or misalignment

- Test electrical connections and sensors

- Calibrate the hydraulic system if necessary

5. What are the safety precautions that must be taken when operating a clamshell bucket?

- Wear appropriate personal protective equipment (PPE)

- Inspect the bucket and rigging before each use

- Maintain a safe distance from overhead power lines

- Avoid working under suspended loads

- Follow the manufacturer’s operating instructions

6. How do you maintain a clamshell bucket to extend its service life?

- Regularly inspect and lubricate all moving parts

- Replace worn or damaged components promptly

- Keep the bucket clean to prevent corrosion

- Store the bucket in a dry and protected location

- Follow the manufacturer’s maintenance recommendations

7. What are the latest advancements in clamshell bucket technology?

- High-strength materials for increased durability

- Optimized bucket designs for improved efficiency

- Automated control systems for enhanced safety and performance

- Remote monitoring capabilities for predictive maintenance

- Electrically powered buckets for reduced emissions and noise

8. Describe your experience in designing and analyzing clamshell buckets using engineering software.

- Proficient in using CAD software such as SolidWorks or AutoCAD

- Expertise in finite element analysis (FEA) software such as ANSYS or Abaqus

- Experience in modeling and simulating clamshell bucket performance

- Understanding of material properties and structural mechanics

- Ability to interpret and present engineering results

9. How do you stay updated on the latest developments in clamshell bucket engineering?

- Attend industry conferences and exhibitions

- Read technical journals and research papers

- Network with other engineers and professionals

- Participate in online forums and discussion groups

- Stay informed about new technologies and products

10. Why are you interested in working as a Clamshell Engineer at our company?

- Passion for engineering and innovation

- Interest in clamshell bucket technology

- Desire to contribute to the development of cutting-edge products

- Attracted by the company’s reputation and commitment to excellence

- Excited about the opportunity to work in a dynamic and collaborative environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clamshell Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clamshell Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clamshell Engineers are responsible for overseeing the installation, operation, and maintenance of clamshell buckets, which are used to move and load bulk materials. They are expected to have a strong understanding of the principles of mechanical engineering, as well as a thorough knowledge of the safety regulations and industry standards associated with the operation of heavy machinery.

1. Installation and Maintenance

Clamshell Engineers are responsible for overseeing the installation of clamshell buckets and ensuring that they are properly secured and calibrated. They also perform routine maintenance on the buckets, including inspections, lubrication, and repairs.

- Inspect clamshell buckets for damage or wear and tear.

- Lubricate and adjust clamshell buckets as needed.

- Troubleshoot and repair clamshell buckets.

2. Operation

Clamshell Engineers are also responsible for operating clamshell buckets. They must be able to safely and efficiently move and load bulk materials, such as coal, ore, and sand.

- Operate clamshell buckets to move and load bulk materials.

- Monitor the performance of clamshell buckets and make adjustments as needed.

- Ensure that clamshell buckets are operated in a safe and efficient manner.

3. Safety

Clamshell Engineers are responsible for ensuring the safety of themselves and others when working with clamshell buckets. They must be familiar with the safety regulations and industry standards associated with the operation of heavy machinery, and they must follow all safety procedures.

- Follow all safety regulations and industry standards.

- Wear appropriate safety gear.

- Inspect the work area for hazards.

4. Troubleshooting

Clamshell Engineers must be able to troubleshoot and repair clamshell buckets when they encounter problems. They must be able to identify the source of the problem and take the necessary steps to resolve it.

- Identify and resolve problems with clamshell buckets.

- Develop and implement solutions to improve the performance of clamshell buckets.

- Recommend upgrades or modifications to clamshell buckets.

Interview Tips

In order to ace an interview for a Clamshell Engineer position, it is important to be prepared to answer questions about your experience, skills, and knowledge. Here are a few tips to help you prepare:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- “Tell me about yourself.”

- “Why are you interested in working for this company?”

- “What are your strengths and weaknesses?”

3. Prepare questions to ask the interviewer

Asking the interviewer questions is a great way to show that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

- “What are the biggest challenges facing the company right now?”

- “What are the company’s goals for the next year?”

- “What is the company’s culture like?”

4. Dress professionally and arrive on time

First impressions matter. When you go for your interview, it is important to dress professionally and arrive on time. This will show the interviewer that you are respectful of their time and that you are serious about the position.

- Wear a suit or business casual attire.

- Arrive 15 minutes early for your interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clamshell Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.