Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clamshell Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clamshell Operator so you can tailor your answers to impress potential employers.

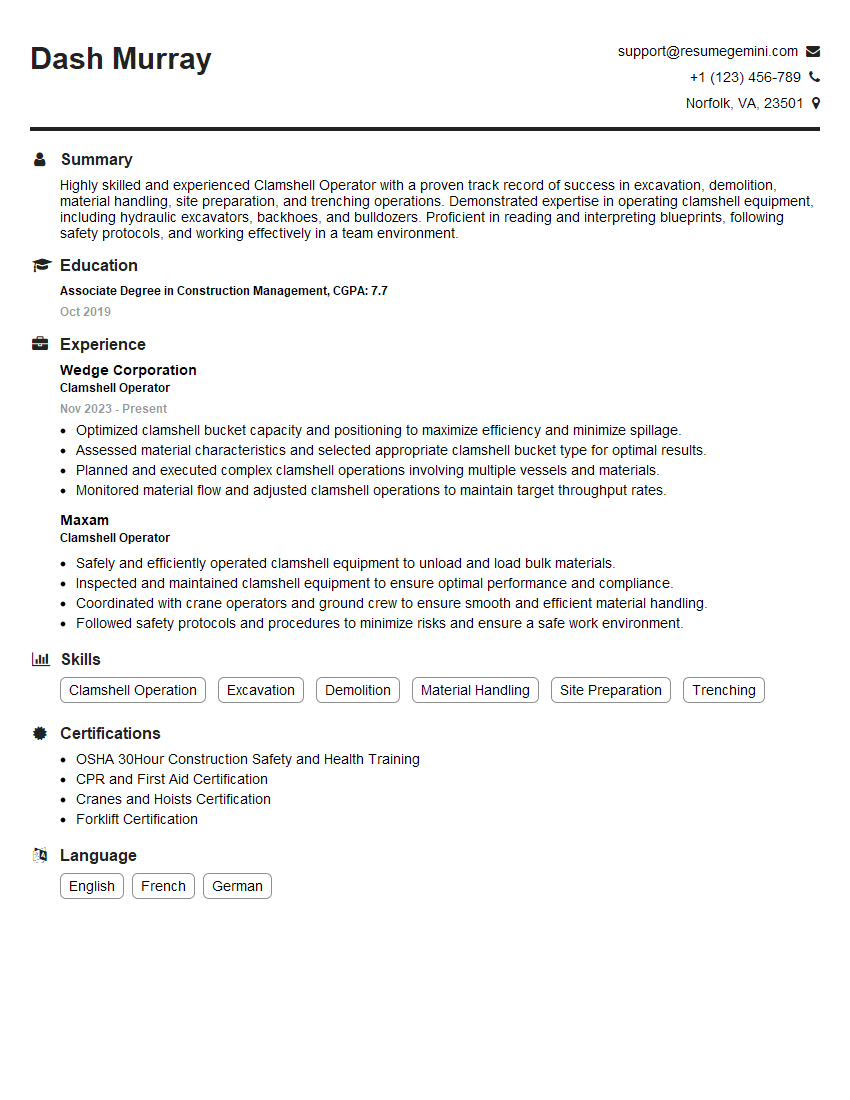

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clamshell Operator

1. Describe the key responsibilities of a Clamshell Operator.

The primary responsibilities of a Clamshell Operator include:

- Operating clamshell buckets to load and unload materials such as sand, gravel, and rocks.

- Maintaining and servicing clamshell equipment, including daily inspections and minor repairs.

- Following safety protocols and regulations for the operation of heavy machinery.

- Monitoring the condition of materials being loaded and unloaded, and reporting any issues.

- Working effectively in a team environment to ensure efficient and safe material handling.

2. Explain the difference between a clamshell bucket and an orange peel bucket.

- Clamshell buckets have two hinged jaws that open and close like a clam, while orange peel buckets have multiple tines that grab and hold materials.

- Clamshell buckets are ideal for handling loose and bulky materials, while orange peel buckets are better suited for handling heavier and denser materials.

- Clamshell buckets are often used in dredging operations, while orange peel buckets are commonly used in demolition and scrap handling.

3. What are the safety precautions that must be taken when operating a clamshell bucket?

When operating a clamshell bucket, the following safety precautions must be observed:

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and gloves.

- Inspect the equipment before each use, checking for any damage or leaks.

- Be aware of surroundings and potential hazards, such as overhead power lines and uneven ground.

- Never overload the bucket or exceed the rated capacity of the equipment.

- Keep the bucket close to the ground when not in use to prevent accidental contact with overhead obstacles.

4. How do you troubleshoot common problems that may occur with a clamshell bucket?

Mechanical Problems

- Damaged jaws or tines: Inspect for cracks or breaks and replace if necessary.

- Hydraulic leaks: Check for loose fittings or damaged hoses and tighten or replace as needed.

- Electrical issues: Verify that all electrical connections are secure and that there are no damaged wires.

Operational Problems

- Material not loading properly: Check the bucket size and shape for compatibility with the material being loaded.

- Difficulty closing the bucket: Inspect for objects stuck in the jaws or tines and remove them.

- Bucket swinging excessively: Adjust the boom speed or counterweight to stabilize the bucket.

5. What is the importance of proper maintenance for clamshell buckets?

Regular maintenance is crucial for clamshell buckets to ensure:

- Safe operation: Regular inspections and maintenance can identify potential issues and prevent accidents.

- Extended equipment life: Proper maintenance reduces wear and tear, extending the lifespan of the bucket.

- Improved performance: Well-maintained buckets operate more efficiently, allowing for faster and more accurate material handling.

- Reduced downtime: Proactive maintenance minimizes the risk of unexpected breakdowns, reducing downtime and increasing productivity.

6. How do you ensure the accuracy and efficiency of material loading and unloading using a clamshell bucket?

- Proper bucket selection: Choose the right bucket size and type for the specific material and application.

- Precise positioning: Carefully position the bucket over the loading or unloading area to minimize spillage and ensure accurate placement.

- Controlled operation: Use smooth and controlled movements to avoid damaging materials or equipment.

- Team coordination: Communicate effectively with other crew members to ensure coordinated loading and unloading operations.

7. What is your approach to working in a team environment as a Clamshell Operator?

- Effective communication: Maintain open communication with team members to ensure clear understanding of tasks and avoid misunderstandings.

- Collaborative effort: Work cooperatively with colleagues to achieve common goals and support each other in challenging situations.

- Respect for diversity: Value and respect the contributions of team members with different backgrounds and perspectives.

- Problem-solving: Actively participate in problem-solving discussions and contribute ideas to overcome challenges and improve processes.

8. How do you stay updated with industry best practices and technological advancements related to clamshell bucket operations?

- Attend industry conferences and workshops: Participate in events that showcase new technologies and provide opportunities for knowledge sharing.

- Read industry publications: Stay informed about the latest trends, techniques, and safety regulations through industry magazines and journals.

- Network with professionals: Engage with other Clamshell Operators and experts in the field to exchange knowledge and insights.

- Seek training and certification: Pursue additional training and certifications to enhance skills and demonstrate commitment to professional development.

9. Describe a situation where you successfully resolved a complex problem while operating a clamshell bucket.

Describe a specific instance where you encountered a challenging situation, identified the root cause, and implemented a solution to resolve the issue efficiently.

10. Why are you interested in this Clamshell Operator position with our company?

Explain your motivation for applying to the position and highlight your interest in the company’s industry, values, or specific projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clamshell Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clamshell Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clamshell operators are responsible for operating clamshell cranes to load and unload materials in a safe and efficient manner. Key responsibilities include:1. Operating Clamshell Cranes

Clamshell operators must be proficient in operating clamshell cranes to load and unload materials from ships, barges, and other vessels.

- Ensuring that the crane is in good working condition

- Loading and unloading materials efficiently and safely

- Adjusting the crane’s settings to accommodate different materials

2. Inspecting Equipment

Clamshell operators must regularly inspect their equipment to ensure that it is in good working condition. This includes inspecting the crane, the bucket, and the rigging.

- Identifying and reporting any potential safety hazards

- Maintaining equipment to ensure optimal performance

- Performing minor repairs and maintenance tasks

3. Maintaining Safety

Clamshell operators must always prioritize safety when operating cranes. This includes following all safety regulations, wearing appropriate safety gear, and being aware of their surroundings.

- Following all safety protocols and procedures

- Maintaining a safe work area

- Being aware of potential hazards and taking steps to mitigate them

4. Communicating Effectively

Clamshell operators must be able to communicate effectively with other crew members, including crane operators, deckhands, and supervisors.

- Relaying information clearly and concisely

- Listening to and understanding instructions

- Coordinating with other crew members to ensure a smooth operation

Interview Tips

In order to ace your interview for a clamshell operator position, it is important to be prepared. Here are a few tips:1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work for the company

2. Prepare Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is important to prepare answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice your answers out loud

- Tailor your answers to the specific company and position

- Be honest and authentic in your answers

3. Demonstrate Your Skills and Experience

During your interview, you will need to demonstrate your skills and experience. This can be done by providing specific examples of your work experience. For example, you could talk about a time when you successfully resolved a problem or a time when you exceeded expectations.

- Use the STAR method to answer interview questions

- Quantify your accomplishments whenever possible

- Be prepared to talk about your safety record

4. Ask Questions

At the end of your interview, be sure to ask questions of your own. This shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s safety culture

- Ask about the training and development opportunities available

- Ask about the company’s plans for the future

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Clamshell Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Clamshell Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.