Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clarifying Plant Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

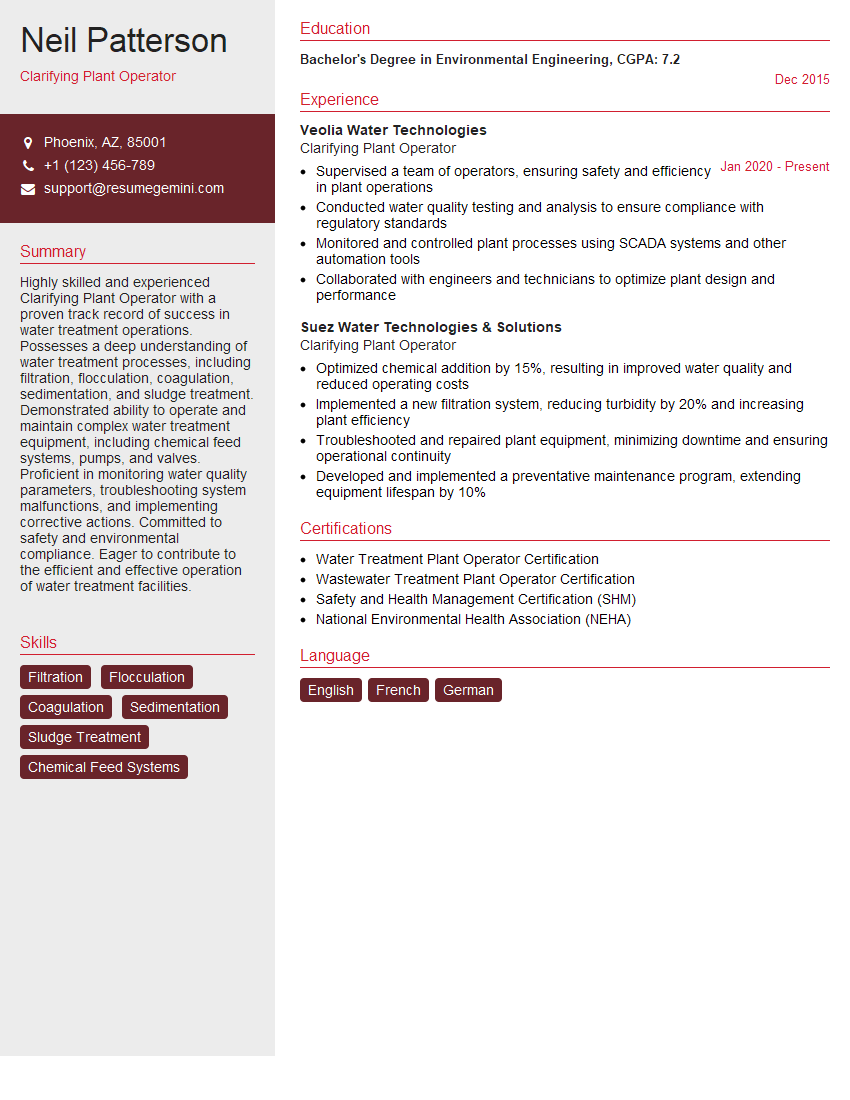

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clarifying Plant Operator

1. What are the key responsibilities of a Clarifying Plant Operator?

As a Clarifying Plant Operator, my primary responsibilities would include:

- Monitoring and controlling the clarification process to ensure efficient removal of impurities

- Operating and maintaining clarification equipment, including thickeners, filters, and centrifuges

- Conducting routine inspections and maintenance to prevent breakdowns and ensure optimal performance

- Taking samples and performing quality control tests to monitor the clarity and purity of the treated water

- Adjusting process parameters and making necessary adjustments to optimize clarification efficiency

2. What specific techniques are used in clarification processes?

Chemical Treatment

- Coagulation: Adding chemicals to neutralize charges and form flocs

- Flocculation: Gentle mixing to promote floc growth and aggregation

Physical Treatment

- Sedimentation: Allowing flocs to settle under gravity in thickeners

- Filtration: Passing water through filters to remove remaining flocs

- Centrifugation: Using centrifugal force to separate flocs from water

Biological Treatment

- Activated sludge process: Using microorganisms to consume and remove impurities

- Membrane bioreactors: Combining biological treatment with membrane filtration

3. How do you handle process deviations or upsets in a clarifying plant?

To effectively handle process deviations or upsets, I would follow a systematic approach:

- Identify the deviation or upset by monitoring process parameters and analyzing samples

- Determine the root cause of the problem by investigating potential factors such as chemical dosing, equipment malfunction, or influent quality

- Implement corrective actions to address the root cause, including adjusting process parameters, calibrating equipment, or contacting maintenance personnel

- Monitor the situation closely to ensure that the deviation or upset has been resolved and the process is operating smoothly

- Document the incident and corrective actions taken for future reference and analysis

4. What safety protocols are essential in a clarifying plant?

In a clarifying plant, adhering to strict safety protocols is crucial to ensure the well-being of operators and the integrity of the process.

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing

- Following established lockout/tagout procedures when working on equipment

- Being aware of potential hazards associated with chemicals and handling them with proper care

- Maintaining a clean and organized work environment to prevent accidents and spills

- Participating in regular safety training and drills to stay informed and prepared

5. How do you ensure the quality of clarified water meets regulatory standards?

Ensuring that the clarified water meets regulatory standards is paramount.

- Regularly conducting quality control tests on water samples to assess parameters such as turbidity, pH, and microbiological content

- Maintaining accurate records and documentation of test results for compliance and analysis

- Implementing corrective actions promptly if test results indicate deviations from standards

- Collaborating with the quality control department to identify and address potential sources of contamination

- Staying updated on industry best practices and regulatory changes to ensure ongoing compliance

6. What are your experiences in optimizing the efficiency of a clarification process?

Optimizing the efficiency of a clarification process is crucial for effective water treatment.

- Fine-tuning chemical dosing rates to enhance coagulation and flocculation

- Adjusting mixing and settling times to improve floc formation and removal

- Implementing advanced filtration techniques, such as ultrafiltration or microfiltration, for enhanced clarity

- Upgrading equipment and automation to improve process control and reliability

- Collaborating with process engineers to identify opportunities for process optimization and efficiency gains

7. How do you maintain and troubleshoot the equipment used in a clarification plant?

Preventive Maintenance

- Regularly inspecting equipment for wear and tear

- Performing scheduled maintenance and calibration according to manufacturer’s guidelines

- Replacing or repairing worn-out components promptly

Troubleshooting

- Identifying potential problems by monitoring equipment performance and analyzing alarms

- Consulting technical manuals and troubleshooting guides

- Diagnosing and resolving issues through systematic testing and repair procedures

8. What types of data analysis and reporting are typically required in a clarification plant?

Data analysis and reporting are essential for evaluating process performance and ensuring compliance.

- Collecting and analyzing data on process parameters, such as flow rates, chemical dosages, and turbidity levels

- Preparing daily, weekly, and monthly reports summarizing process performance and any deviations or upsets

- Using historical data to identify trends, optimize process settings, and predict maintenance needs

- Communicating findings and recommendations to supervisors, managers, and regulatory authorities

9. How do you stay up-to-date on advancements in clarification technologies?

To stay current with advancements in clarification technologies, I:

- Attend industry conferences and workshops

- Read technical publications and journals

- Participate in online forums and discussion groups

- Network with professionals in the field

- Explore new technologies and research findings through vendor demonstrations and pilot testing

10. What qualities and skills make an effective Clarifying Plant Operator?

Effective Clarifying Plant Operators possess a combination of technical expertise and soft skills.

- Strong understanding of clarification processes and equipment

- Attention to detail and commitment to quality

- Problem-solving abilities and analytical thinking

- Good communication and interpersonal skills

- Commitment to safety and adherence to protocols

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clarifying Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clarifying Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clarifying Plant Operators play a crucial role in the manufacturing process, ensuring the production of high-quality and clear liquids.

1. Operating and Monitoring Equipment

Primary responsibilities include operating and monitoring various equipment and machinery, such as clarifiers, pumps, and piping systems.

- Ensure efficient equipment operation to achieve desired clarification levels.

- Monitor process parameters like flow rates, temperatures, and pressures.

2. Maintaining and Troubleshooting

Maintaining and troubleshooting equipment and systems is essential to prevent interruptions and ensure smooth operation.

- Perform routine maintenance tasks, including cleaning, lubrication, and adjustments.

- Troubleshoot and resolve equipment malfunctions promptly to minimize downtime.

3. Quality Control and Analysis

Clarifying Plant Operators play a key role in quality control, ensuring the clarity and purity of products.

- Monitor quality parameters, such as turbidity, color, and pH.

- Conduct routine tests to ensure compliance with quality standards and specifications.

4. Safety and Environmental Compliance

Adhering to safety protocols and environmental regulations is paramount in any industrial setting.

- Follow established safety procedures to minimize risks and ensure a safe work environment.

- Comply with environmental regulations related to waste management and emissions.

Interview Tips

To ace your interview for a Clarifying Plant Operator position, consider the following preparation tips:

1. Research the Company and Role

Research the company and the specific role to gain an in-depth understanding of their operations and requirements.

- Review the company’s website, industry news, and social media profiles.

- Thoroughly study the job description and identify the key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate your capabilities.

- Highlight your experience in operating and maintaining industrial equipment.

- Showcase your knowledge of clarification processes and quality control techniques.

3. Prepare for Behavioral Questions

Behavioral questions assess your past performance and soft skills. Prepare examples that demonstrate your problem-solving, teamwork, and communication abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your adaptability, attention to detail, and willingness to learn.

4. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Prepare concise and compelling responses that highlight your qualifications and enthusiasm.

- Research common technical questions related to clarifying processes and equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clarifying Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!