Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clay Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clay Machine Operator so you can tailor your answers to impress potential employers.

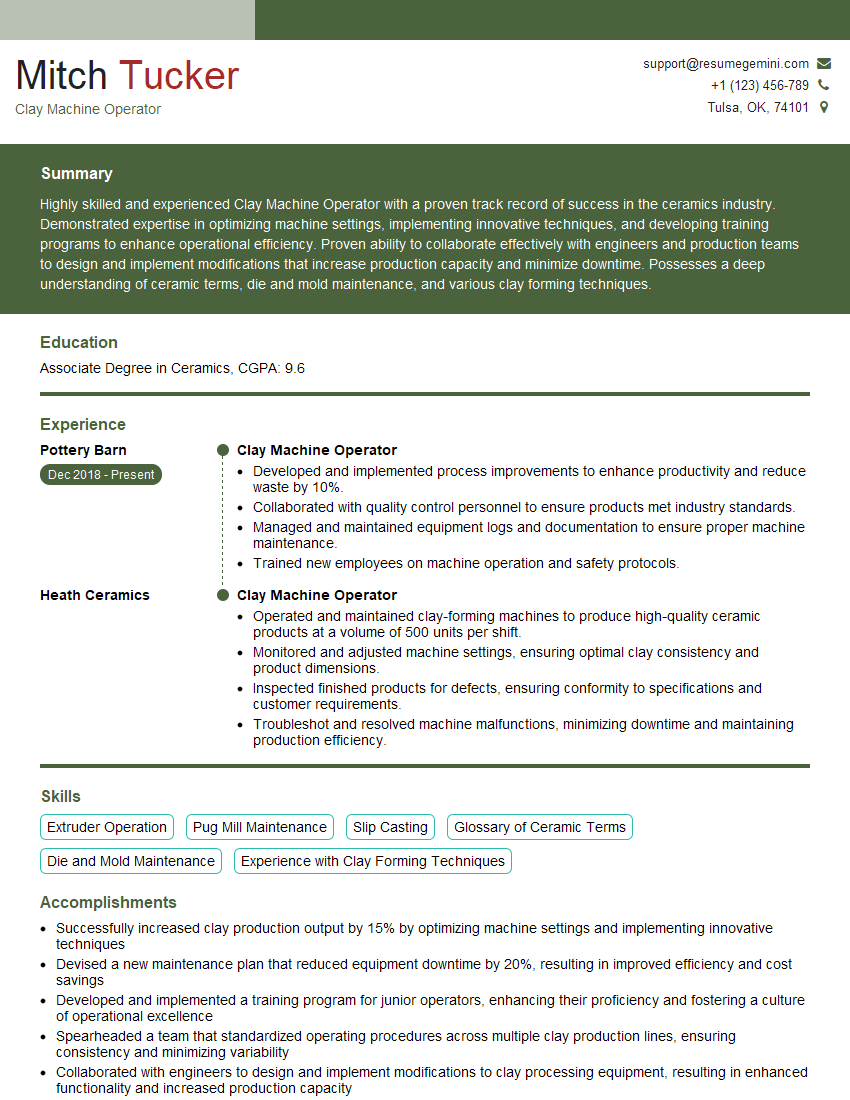

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clay Machine Operator

1. What is the role of a Clay Machine Operator?

As a Clay Machine Operator, I would be responsible for:

- Monitoring and operating clay-making machinery to ensure the production of high-quality clay products

- Controlling the flow of clay through the machine, adjusting settings to maintain optimum consistency and moisture levels

- Performing routine maintenance and repairs on equipment to prevent breakdowns and ensure smooth operations

- Working with other team members to ensure efficient production and meet targets

2. How do you maintain a safe and efficient work environment in the clay production area?

Upholding Safety Protocols

- Adhering to all safety regulations and guidelines

- Wearing appropriate personal protective equipment (PPE)

- Identifying potential hazards and implementing safety measures to mitigate them

Promoting Efficiency

- Organizing the workspace for optimal workflow

- Following established work procedures to maximize productivity

- Utilizing available tools and resources effectively

3. Describe the different types of clays and their properties.

Different types of clays include:

- Kaolin: Pure white clay known for its high brightness and low impurity content

- Ball Clay: Plastic clay with high plasticity and water absorption properties

- Fire Clay: Heat-resistant clay used in high-temperature applications

- Bentonite: Swelling clay used as a binder and sealant

- Illite: Clay with high potassium content and good strength properties

4. Explain the process of preparing clay for production.

- Extraction: Acquiring clay from natural deposits

- Grinding: Breaking down clay into smaller particles

- Mixing: Blending different types of clays and additives to achieve desired properties

- Aging: Storing clay mixture for a period of time to mature and improve workability

5. Describe the importance of moisture control in clay production.

- Moisture content affects the plasticity and workability of clay

- Proper moisture levels ensure optimal extrusion and molding processes

- Excessive moisture can lead to cracking and deformation, while insufficient moisture can result in brittleness

6. How do you troubleshoot common issues in clay production, such as cracking, uneven extrusion, and color variation?

Cracking

- Check clay moisture levels and adjust as needed

- Inspect extrusion equipment for wear or blockages

- Consider adding plasticizers to improve clay workability

Uneven Extrusion

- Ensure uniform feeding of clay into the extruder

- Calibrate extruder settings for optimal pressure and flow

- Inspect dies and nozzles for damage or clogging

Color Variation

- Verify the consistency of clay composition and mixing

- Check for contamination from other materials

- Consider using colorants or dyes to achieve desired shades

7. What is the significance of quality control in clay production?

- Ensures consistency and meets customer specifications

- Minimizes defects and reduces production costs

- Maintains brand reputation and customer satisfaction

8. Describe your experience in operating and maintaining clay-making machinery.

- List specific machines operated, including extruders, pug mills, and dryers

- Highlight maintenance tasks performed, such as cleaning, lubrication, and component replacement

- Quantify results achieved through effective maintenance, such as increased uptime and reduced downtime

9. How do you manage production schedules to meet customer demands?

- Understanding production capacity and lead times

- Coordinating with other departments to ensure timely material availability

- Monitoring progress and making adjustments to optimize workflow

- Communicating regularly with customers to manage expectations

10. What are the key challenges you have faced in previous clay production roles and how did you overcome them?

Describe specific challenges, such as equipment breakdowns, quality issues, or production bottlenecks.

- Explain the steps taken to identify and understand the root cause

- Highlight the solutions implemented and the positive outcomes achieved

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clay Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clay Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clay Machine Operators are responsible for operating and maintaining clay-forming machines in the production of ceramic products, such as bricks, tiles, and pottery. Their primary duties include:

1. Machine Operation

Operate and control clay-forming machines, including pug mills, extruders, and presses.

- Monitor and adjust machine settings to ensure optimal production.

- Troubleshoot and resolve machine malfunctions promptly.

2. Clay Preparation

Prepare and mix clay according to specified formulations.

- Add water, additives, and other materials to achieve desired consistency and characteristics.

- Maintain proper moisture content and workability of the clay.

3. Production Monitoring

Monitor production processes and ensure product quality.

- Inspect clay products for defects and consistency.

- Adjust machine settings as needed to maintain desired specifications.

4. Equipment Maintenance

Perform routine maintenance and cleaning of clay-forming machines.

- Lubricate and adjust machine components.

- Replace worn or damaged parts as necessary.

Interview Tips

Preparing for an interview as a Clay Machine Operator requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s products, values, and history. Understand the specific responsibilities and requirements of the Clay Machine Operator role.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining clay-forming machinery. Quantify your accomplishments by providing specific examples of how you have improved production efficiency or resolved technical issues.

3. Demonstrate Technical Proficiency

Be prepared to discuss your understanding of clay properties, machine operations, and production processes. Explain how you ensure product quality and maintain equipment in optimal condition.

4. Showcase Safety Awareness

Clay Machine Operators work in industrial environments and must prioritize safety. Highlight your knowledge of safety regulations and procedures, and demonstrate your commitment to maintaining a safe work environment.

5. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?,” and “What are your strengths and weaknesses?”. Tailor your answers to the specific job requirements.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s growth plans, technology advancements, or opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Clay Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.