Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clay Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clay Maker so you can tailor your answers to impress potential employers.

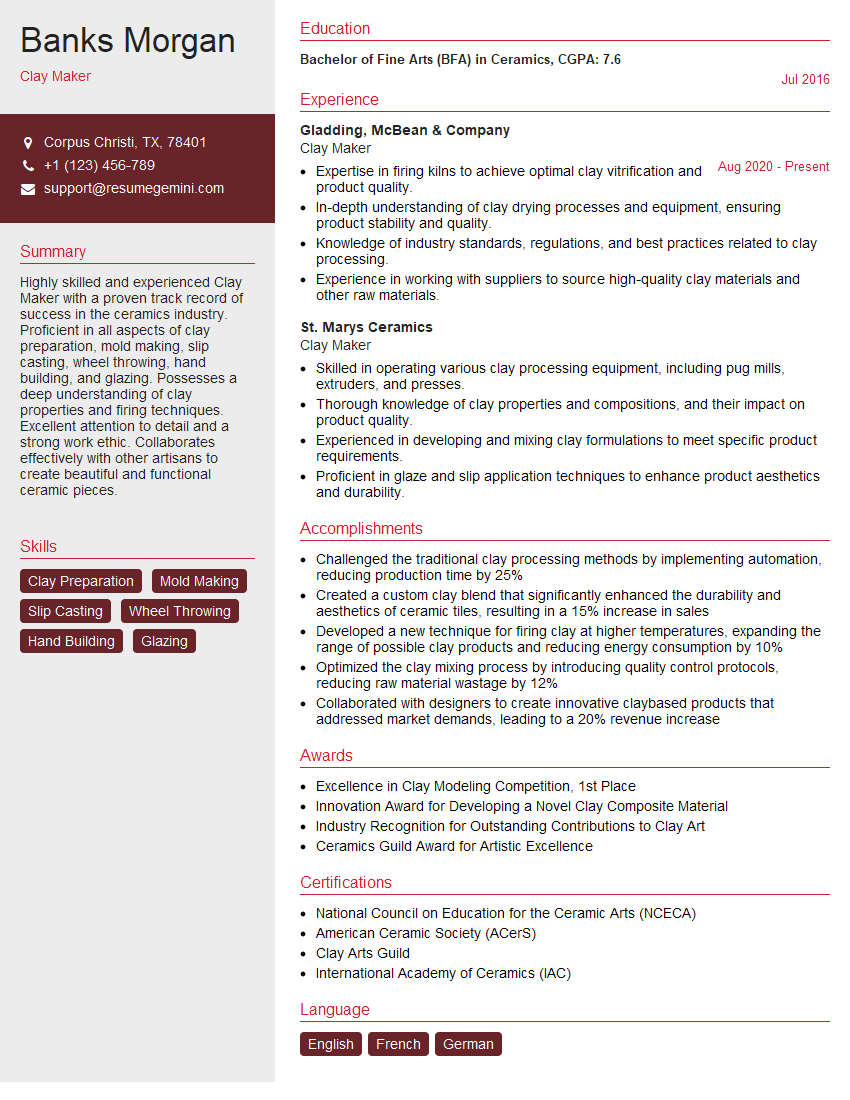

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clay Maker

1. What are the different types of clays and how do they differ in properties?

- Kaolin clay: This is a white clay that is known for its purity and whiteness. It is often used in the production of ceramics, paper, and paint.

- Ball clay: This is a plastic clay that is often used in the production of tiles, sanitary ware, and pottery.

- Stoneware clay: This is a type of clay that is fired at a high temperature, making it strong and durable. It is often used in the production of stoneware pottery.

- Earthenware clay: This is a type of clay that is fired at a low temperature, making it porous and fragile. It is often used in the production of earthenware pottery.

2. What are the key factors that affect the quality of clay?

- The composition of the clay: The composition of the clay will affect its plasticity, strength, and color.

- The particle size of the clay: The particle size of the clay will affect its texture and porosity.

- The presence of impurities: The presence of impurities in the clay can affect its quality.

3. What are the different methods for preparing clay for use?

- Slaking: This is a process of soaking the clay in water to soften it.

- Wedging: This is a process of kneading the clay to remove air bubbles and impurities.

- Rolling: This is a process of rolling the clay out into a thin sheet.

- Extruding: This is a process of forcing the clay through a die to create a specific shape.

4. What are the different techniques for shaping clay?

- Throwing: This is a process of shaping clay on a potter’s wheel.

- Handbuilding: This is a process of shaping clay by hand.

- Casting: This is a process of pouring clay into a mold.

- Pressing: This is a process of pressing clay into a mold.

5. What are the different methods for firing clay?

- Kiln firing: This is a process of firing clay in a kiln.

- Raku firing: This is a process of firing clay in a kiln at a low temperature.

- Pit firing: This is a process of firing clay in a pit in the ground.

6. What are the different types of glazes that can be used on clay?

- Clear glaze: This is a type of glaze that does not add any color to the clay.

- Opaque glaze: This is a type of glaze that adds color to the clay.

- Matt glaze: This is a type of glaze that has a dull finish.

- Glossy glaze: This is a type of glaze that has a shiny finish.

7. What are the key factors that affect the appearance of a fired clay piece?

- The type of clay used

- The firing temperature

- The type of glaze used

- The cooling rate

8. What are the common defects that can occur in fired clay pieces?

- Crazing: This is a network of fine cracks that can occur in the glaze.

- Pinholing: This is a defect that occurs when small bubbles of air are trapped in the glaze.

- Warping: This is a defect that occurs when the clay piece bends or twists during firing.

- Bloating: This is a defect that occurs when the clay piece swells during firing.

9. What are the safety precautions that should be taken when working with clay?

- Wear a dust mask when working with dry clay.

- Wear gloves when working with wet clay.

- Wash your hands thoroughly after working with clay.

- Do not eat or drink in the work area.

10. What are the qualities of a good clay maker?

- A good clay maker should have a strong understanding of the different types of clay and their properties.

- A good clay maker should be able to prepare clay for use correctly.

- A good clay maker should be able to shape clay using a variety of techniques.

- A good clay maker should be able to fire clay correctly.

- A good clay maker should be able to glaze clay correctly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clay Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clay Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Clay Maker

Key Job Responsibilities

Clay makers play a crucial role in the ceramics industry by preparing and manipulating clay for various purposes. Their key responsibilities include:

1. Clay Preparation

Preparing clay by mixing, wedging, and tempering to ensure its consistency, workability, and desired properties.

- Mixing dry clay with water to create a workable paste.

- Wedging or kneading the clay to remove air bubbles and achieve uniform texture.

2. Clay Shaping

Shaping clay into various forms using techniques such as throwing, molding, or hand-building to create pottery, tiles, or other clay products.

- Using a potter’s wheel to throw clay into desired shapes.

- Molding clay into specific forms using molds and slip casting.

- Hand-building clay by pinching, coiling, or sculpting techniques.

3. Kiln Operation

Loading and firing clay products in kilns at predetermined temperatures and durations to achieve desired hardness, strength, and glaze finishes.

- Setting up and monitoring kilns to ensure proper firing conditions.

- Adjusting temperature and firing times to achieve specific clay properties.

4. Clay Testing and Quality Control

Conducting tests to evaluate clay properties such as plasticity, porosity, and firing shrinkage. Ensuring that clay products meet quality standards and specifications.

- Performing tests to determine the suitability of clay for specific applications.

- Inspecting finished clay products for defects or imperfections.

5. Equipment Maintenance and Safety

Maintaining and cleaning clay-working equipment such as pottery wheels, kilns, and mixing machines to ensure their proper functioning and safety.

- Adhering to safety regulations and using appropriate protective gear while handling clay and operating equipment.

- Cleaning and maintaining the work area to ensure a safe and organized environment.

Interview Preparation Tips

To ace the interview for a Clay Maker position, candidates should prepare thoroughly to demonstrate their skills, experience, and enthusiasm for the role.

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and products. Understand the latest trends and developments in the ceramics industry.

- Visit the company website and social media platforms.

- Read industry publications and attend relevant trade shows.

2. Highlight Relevant Skills and Experience

Emphasize your experience in clay preparation, shaping, kiln operation, testing, and quality control. Quantify your accomplishments and provide specific examples to demonstrate your proficiency.

- Highlight your knowledge of different clay types and their properties.

- Showcase your ability to work with a variety of clay-working tools and equipment.

- Provide examples of successful projects or innovations that you have implemented.

3. Prepare for Technical Questions

Expect questions that test your technical knowledge of clay properties, firing techniques, and kiln operations. Be prepared to discuss your understanding of clay chemistry, glazes, and the effects of temperature and firing duration.

- Review the basics of clay science and kiln operation.

- Practice answering questions about different clay types and their applications.

- Be ready to explain the process of glaze application and firing.

4. Practice Your Presentation Skills

Prepare and practice your answers to common interview questions. Speak clearly and concisely, providing specific examples and evidence to support your statements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Ask questions during the interview to show your interest and engagement.

- Be confident, enthusiastic, and professional throughout the interview.

5. Show Your Passion and Creativity

Clay making is an art form that requires creativity and passion. Highlight your love for working with clay and your willingness to explore new techniques and materials.

- Discuss any personal projects or hobbies related to clay.

- Share ideas for innovative clay products or applications.

- Show that you are excited about the opportunity to contribute to the company’s success.

Next Step:

Now that you’re armed with the knowledge of Clay Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Clay Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini