Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clay Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clay Molder so you can tailor your answers to impress potential employers.

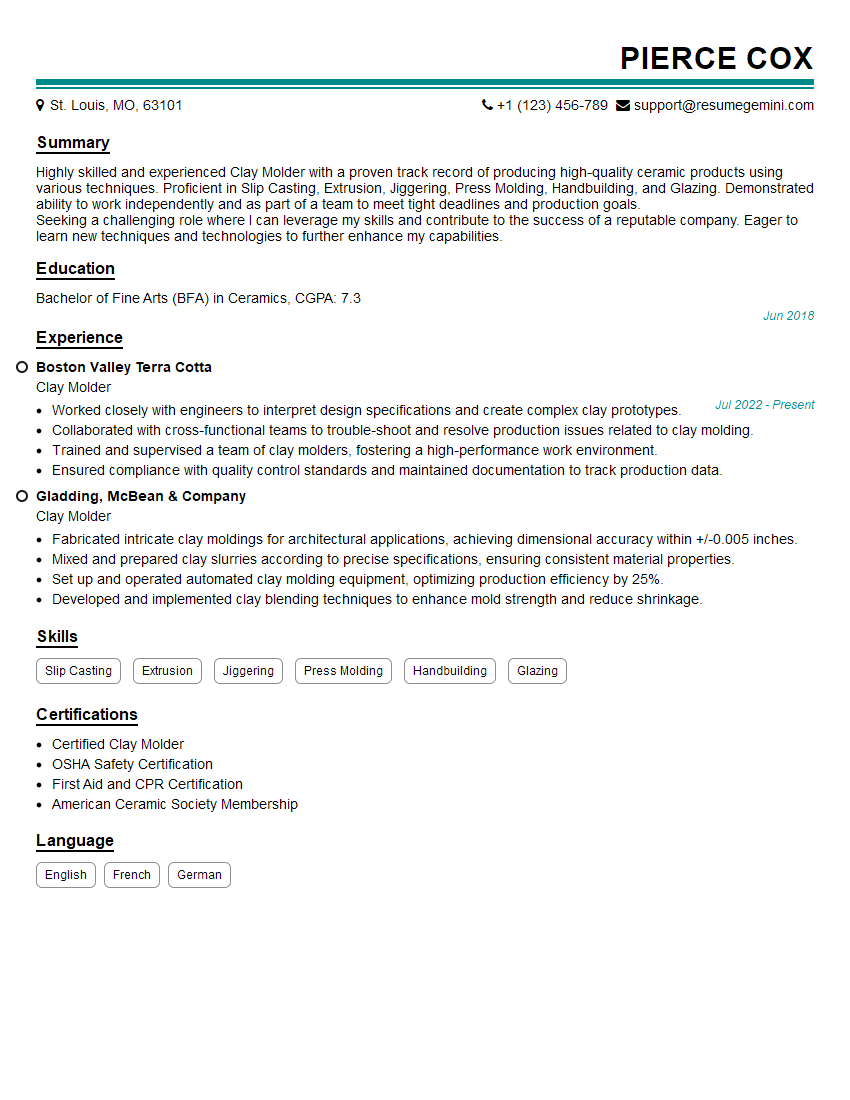

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clay Molder

1. Describe the process of creating a mold for a metal casting?

Here is an outline of the process of creating a mold for a metal casting:

- Create a pattern. The pattern is a replica of the desired casting, and it is used to create the mold.

- Make a mold. The mold is made by packing sand around the pattern and then removing the pattern.

- Pour the metal. Molten metal is poured into the mold and allowed to cool.

- Remove the casting. Once the metal has cooled, the casting is removed from the mold.

2. What are the different types of metal casting processes?

Sand casting

- Sand casting is the most common type of metal casting process.

- It is used to produce a wide variety of castings, from small to large, and from simple to complex.

Investment casting

- Investment casting is a precision casting process that produces high-quality castings with a smooth surface finish.

- It is used to produce castings for a variety of industries, including aerospace, medical, and automotive.

Die casting

- Die casting is a high-pressure casting process that produces castings with a high degree of accuracy and repeatability.

- It is used to produce castings for a variety of industries, including automotive, electronics, and appliances.

Permanent mold casting

- Permanent mold casting is a casting process that uses a metal mold to produce castings.

- It is used to produce castings for a variety of industries, including automotive, aerospace, and medical.

3. What are the advantages and disadvantages of sand casting?

Advantages

- Sand casting is a versatile process that can be used to produce a wide variety of castings.

- It is relatively inexpensive, and it can be used to produce castings in a variety of sizes and shapes.

Disadvantages

- Sand casting can produce castings with a rough surface finish.

- It is not as precise as other casting processes, and it can be difficult to produce castings with a high degree of accuracy.

4. What are the different types of sand used in sand casting?

- Green sand is a mixture of sand, clay, and water.

- Dry sand is a mixture of sand and a bonding agent, such as resin or sodium silicate.

- No-bake sand is a mixture of sand and a chemical binder that does not require baking.

5. What are the different types of patterns used in sand casting?

- Wood patterns are made of wood and are the most common type of pattern.

- Metal patterns are made of metal and are more durable than wood patterns.

- Plastic patterns are made of plastic and are lightweight and easy to handle.

6. What are the different types of gates and risers used in sand casting?

Gates

- Gates are channels that allow molten metal to flow into the mold.

- There are many different types of gates, each with its own advantages and disadvantages.

Risers

- Risers are reservoirs of molten metal that help to feed the casting during solidification.

- Risers are designed to solidify after the casting, so that they can be removed easily.

7. What are the different types of defects that can occur in sand castings?

- Shrinkage defects occur when the casting solidifies and shrinks, causing voids or cracks to form.

- Gas defects occur when gases become trapped in the casting during solidification, causing bubbles or porosity to form.

- Mold defects occur when the mold is not properly prepared or maintained, causing the casting to have a rough surface finish or other defects.

8. How can defects in sand castings be prevented?

- Proper mold design can help to prevent shrinkage defects and gas defects.

- Proper gating and risering can help to prevent shrinkage defects.

- Proper mold preparation and maintenance can help to prevent mold defects.

9. What are the different types of metal casting alloys?

- There are many different types of metal casting alloys, each with its own unique properties.

- Some of the most common metal casting alloys include:

- Aluminum

- Bronze

- Cast iron

- Steel

10. What are the different applications of metal castings?

- Metal castings are used in a wide variety of applications, including:

- Automotive

- Aerospace

- Construction

- Medical

- Industrial

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clay Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clay Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clay Molder is a skilled professional responsible for shaping and molding clay into various products, ensuring adherence to specifications and quality standards.

1. Mold Preparation and Operation

Prepare and set up clay molds, ensuring proper alignment and operation for efficient production.

- Calibrate and maintain molding equipment, including presses, conveyors, and dryers.

- Monitor and adjust mold settings to optimize product quality and minimize defects.

2. Clay Molding and Shaping

Fill molds with clay slurry, ensuring proper density and consistency for desired product shape.

- Operate molding presses to form clay into various products, such as bricks, tiles, and pottery.

- Inspect molded products for defects, such as cracks, voids, or uneven surfaces.

3. Product Finishing and Handling

Trim and finish molded products to remove excess clay and ensure dimensional accuracy.

- Unload molded products from presses and conveyors, placing them on drying racks or kilns for further processing.

- Maintain a clean and organized work area to ensure product quality and safety.

4. Quality Control and Safety

Inspect molded products throughout the production process to identify and correct any defects or deviations from specifications.

- Adhere to established safety protocols and wear appropriate personal protective equipment.

- Report any potential hazards or equipment malfunctions to supervisors for prompt resolution.

Interview Tips

To ace your Clay Molder interview, consider the following preparation tips and interview hacks:

1. Research the Company and Role

Thoroughly research the company’s history, products, and industry standing. Understand the specific requirements of the Clay Molder role, including any specialized skills or certifications.

- Visit the company website and social media pages for relevant information.

- Review job descriptions and industry publications to gain insights into the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in clay molding, mold preparation, and quality control. Showcase your understanding of clay properties, molding techniques, and safety protocols.

- Quantify your accomplishments with specific examples and metrics, demonstrating your impact on production efficiency or product quality.

- If you lack direct Clay Molder experience, highlight transferable skills from related fields, such as manufacturing or construction.

3. Demonstrate Attention to Detail

Clay molding requires precision and meticulous attention to detail. In your interview, emphasize your ability to identify and correct defects, ensuring product quality and adherence to specifications.

- Provide examples of how you have implemented quality control measures or identified and resolved issues in previous roles.

- Show your understanding of clay properties and how they impact product characteristics.

4. Be Prepared for Technical Questions

Anticipate technical questions related to clay molding, such as mold design, clay slurry preparation, or kiln operation. Brush up on your knowledge of these topics and be prepared to discuss them in detail.

- Study industry standards and best practices for clay molding.

- Prepare for questions about equipment calibration, troubleshooting, and maintenance.

5. Seek Opportunities to Showcase Your Skills

If possible, request a plant tour or a hands-on demonstration during your interview. This will allow you to showcase your skills and show your interest in the practical aspects of the job.

- Observe the molding process and ask questions about equipment and techniques.

- Demonstrate your ability to handle clay and operate molding machinery, if applicable.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clay Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!