Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Clay Plant Treater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Clay Plant Treater so you can tailor your answers to impress potential employers.

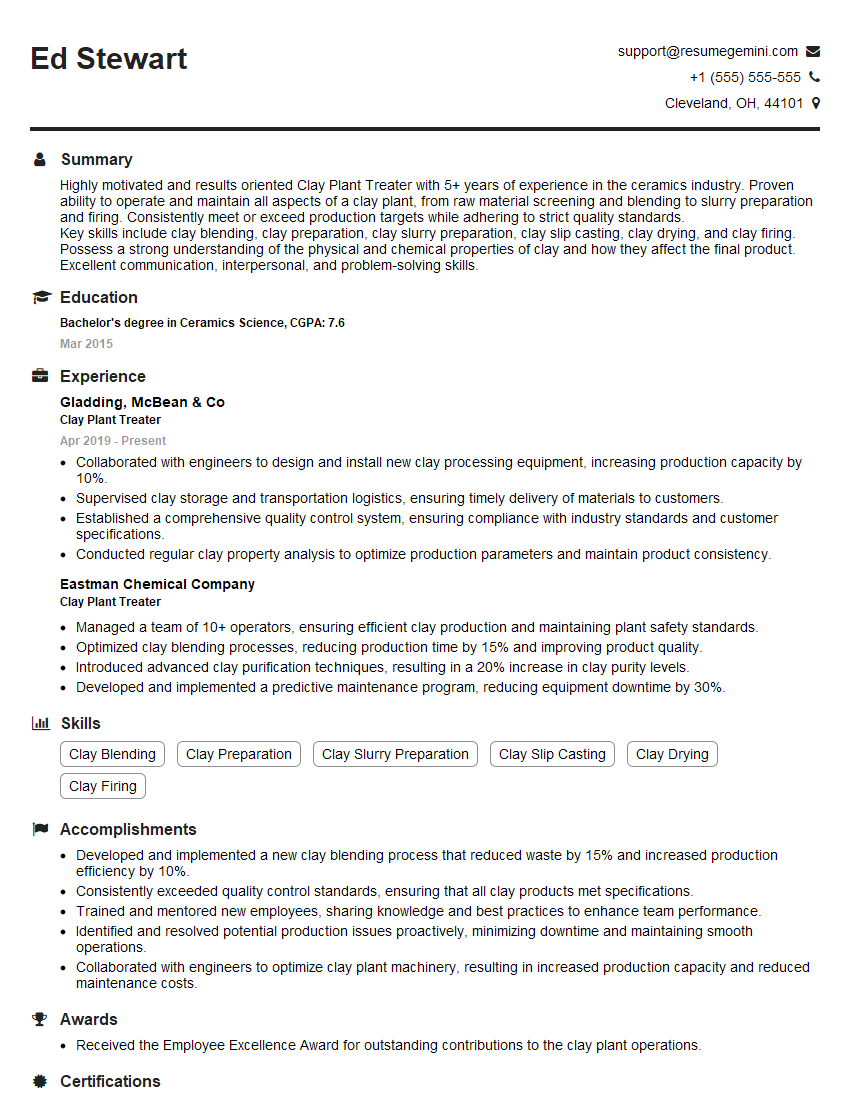

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clay Plant Treater

1. What are the different types of clays used in ceramics and their properties?

There are various types of clays used in ceramics, each with unique properties:

- Kaolin: Fine-grained, white clay known for its high plasticity and whiteness.

- Ball Clay: Plastic clay with high shrinkage and good strength.

- Stoneware Clay: Durable clay with a higher firing temperature, resulting in a dense and non-porous body.

- Earthenware Clay: Coarse-grained clay with low plasticity, often used for making porous items like flower pots.

- Porcelain Clay: A combination of kaolin and other minerals, known for its translucency and high firing temperature.

2. Describe the process of clay preparation for casting.

Preparing clay for casting involves several steps:

- Mixing: Combining dry clay powder with water to form a slurry.

- De-airing: Removing air bubbles from the clay slurry using a vacuum.

- Aging: Allowing the clay to rest for a period to allow the particles to hydrate and stabilize.

- Pugging: Wedging the clay to remove any remaining air pockets and achieve a uniform consistency.

- Casting: Pouring the prepared clay slip into a mold and allowing it to set.

3. Explain the difference between wet and dry pressing in ceramic manufacturing.

Wet pressing and dry pressing are two different methods of forming ceramic products:

- Wet Pressing: Involves using a clay slip that is poured into a mold and pressed under pressure. The excess water is expelled, leaving a dense and strong body.

- Dry Pressing: Utilizes a powdered clay that is compressed in a mold under high pressure. The resulting product has a higher porosity and lower strength compared to wet-pressed items.

4. What is the role of a flocculant in clay treatment?

- A flocculant is an additive that is used to promote the formation of larger and stronger clay particles in a slurry.

- This helps to improve the de-airing and casting processes by facilitating the removal of air bubbles and creating a more stable suspension.

5. How do you determine the firing temperature for a particular clay body?

- The firing temperature for a clay body is determined through a process of testing and experimentation.

- By creating test pieces and firing them at different temperatures, the optimal temperature for achieving the desired level of vitrification, color, and strength can be determined.

6. Describe the process of glazing a ceramic piece.

- Glazing involves coating a fired ceramic piece with a liquid suspension of minerals and glass-forming materials.

- The glaze is applied by dipping, pouring, or spraying, and is then fired at a high temperature, causing it to fuse and create a glass-like coating on the surface.

7. What are the factors that affect the shrinkage of clay during drying and firing?

- Clay type: Different clays have different shrinkage rates due to variations in their mineral composition and particle size.

- Water content: The amount of water in the clay slurry affects the shrinkage, with higher water content leading to higher shrinkage.

- Firing temperature: Higher firing temperatures result in higher shrinkage as the clay vitrifies and the pores close.

- Atmosphere: The firing atmosphere (oxidizing or reducing) can also influence shrinkage.

8. How do you troubleshoot defects in glazed ceramics?

- Identifying the type of defect (e.g., pinholes, crawling, crazing) is crucial.

- The glaze formulation, firing temperature, and cooling rate are some of the factors that can be adjusted to address specific defects.

9. Describe the role of kiln management in the firing process.

Kiln management is critical to ensure even heating and cooling rates during the firing process.

- Temperature control: Monitoring and adjusting the kiln temperature according to the firing schedule is essential.

- Atmosphere control: Maintaining the desired firing atmosphere (oxidizing or reducing) is important for achieving the desired color and finish.

- Cooling rate: Carefully controlling the cooling rate can prevent thermal stress and defects in the fired ware.

10. How do you ensure the quality and consistency of ceramic products?

- Standardized processes: Establishing clear and documented procedures for all aspects of production.

- Quality control: Implementing regular testing and inspection throughout the process to identify and correct any deviations.

- Continuous improvement: Regularly reviewing and updating processes to enhance efficiency and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clay Plant Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clay Plant Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clay Plant Treaters play a crucial role in the preparation and processing of clay products, ensuring their quality and adherence to specifications.

1. Clay Preparation and Treatment

They are responsible for receiving, storing, and preparing raw clay materials. This involves:

- Inspecting incoming clay shipments to ensure adherence to specifications.

- Blending clay from different sources to achieve desired composition.

- Adding chemicals and other additives to adjust clay properties.

- Controlling moisture content through drying or adding water.

2. Clay Product Formation

Clay Plant Treaters assist in shaping and forming clay products. They operate various equipment, such as:

- Pug mills to mix and knead clay into a homogenous mass.

- Extruders to shape the clay into desired forms (e.g., bricks, tiles, pipes).

- Molding presses to create specific product shapes.

3. Process Monitoring and Control

They monitor and control the clay treatment and forming processes to ensure product quality. This includes:

- Continuously checking clay properties (e.g., moisture content, plasticity).

- Adjusting equipment settings to maintain optimal conditions.

- Performing daily or scheduled quality control tests.

4. Equipment Maintenance

Clay Plant Treaters maintain and clean the equipment used in the clay preparation and forming processes. They:

- Lubricate moving parts and check for wear and tear.

- Clean and unclog machines to prevent breakdowns.

- Perform minor repairs and report any major issues.

Interview Preparation Tips

To ace an interview for a Clay Plant Treater position, candidates should prepare thoroughly. Here are some key tips:

1. Research the Company and Industry

Gather information about the company’s profile, mission, values, and industry trends. This helps you understand the organization’s culture and the nature of the role.

2. Practice Answering Common Interview Questions

Review typical interview questions related to the position. Prepare thoughtful and concise responses that highlight your relevant skills and experience. Consider using the “STAR method” to structure your answers.

3. Emphasize Technical Skills and Process Knowledge

Demonstrate your proficiency in clay preparation, treatment, and forming techniques. Explain how you achieve consistent product quality and adhere to industry standards.

4. Highlight Quality Control and Safety Awareness

Emphasize your understanding of quality control procedures and adherence to safety regulations. Showcase your ability to identify and mitigate potential hazards in the workplace.

5. Express Interest and Enthusiasm

Convey your genuine interest in the position and the clay industry. Show your enthusiasm for the role and how you can contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clay Plant Treater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!