Feeling lost in a sea of interview questions? Landed that dream interview for Clay Preparation Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Clay Preparation Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

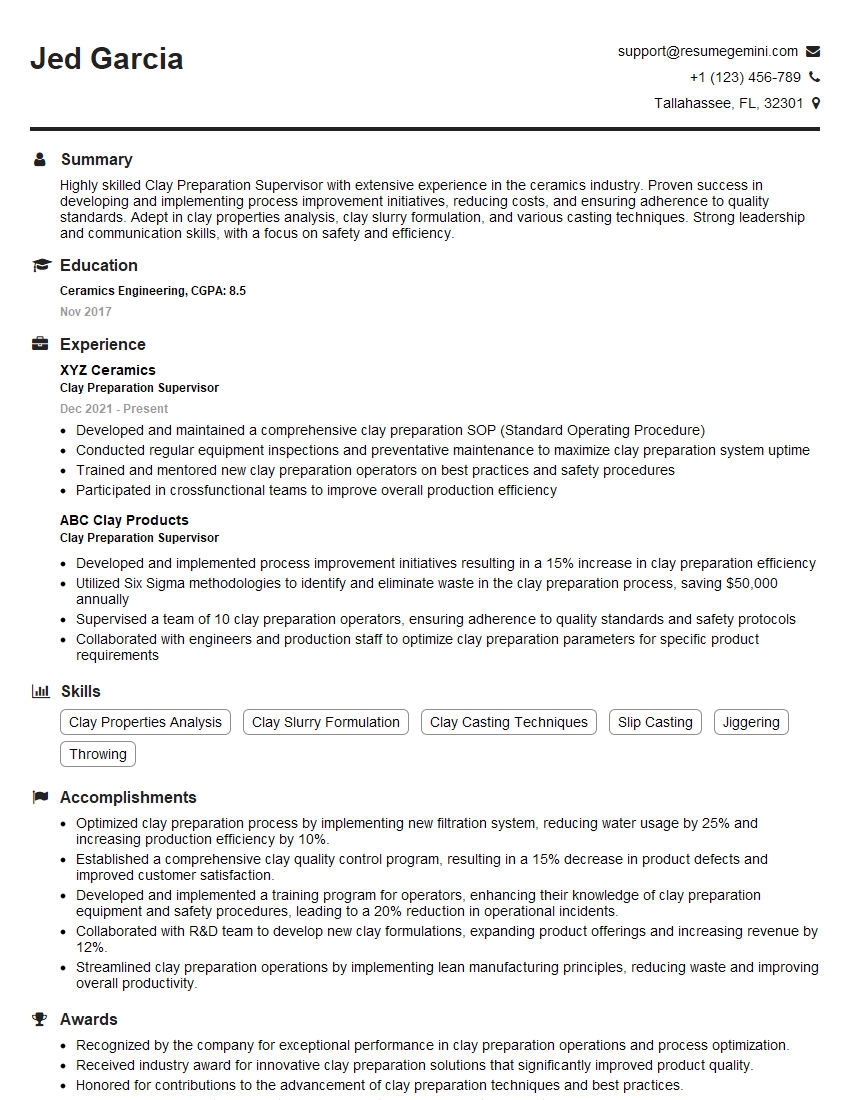

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clay Preparation Supervisor

1. Explain the process of clay preparation in detail?

The process of clay preparation involves several key steps:

- Crushing: The raw clay is crushed into smaller pieces to reduce its particle size.

- Screening: The crushed clay is screened to remove oversized particles and impurities.

- Mixing: The screened clay is mixed with water and other additives, such as binders and pigments, to form a homogeneous slurry.

- Aging: The slurry is aged for a period of time to allow the clay particles to fully hydrate and swell.

- Dewatering: The aged slurry is dewatered using filter presses or other methods to remove excess water and achieve the desired moisture content.

2. What are the key quality control parameters for clay preparation?

Testing Methods

- Moisture content: Determines the amount of water present in the clay.

- Particle size distribution: Measures the distribution of particle sizes in the clay.

- Plasticity: Assesses the workability and molding properties of the clay.

- pH: Indicates the acidity or alkalinity of the clay.

Maintaining Quality

- Regular testing and monitoring of key parameters.

- Adjusting process conditions, such as mixing time and water content, to meet specifications.

- Implementing quality control measures throughout the process.

3. How do you ensure the consistency of clay preparation across different batches?

Ensuring consistency involves:

- Standardized procedures: Establishing clear and detailed procedures for each step of the preparation process.

- Equipment calibration: Regularly calibrating and maintaining all equipment used in the process.

- Operator training: Providing comprehensive training to operators to ensure they follow established procedures consistently.

- Quality control testing: Conducting regular testing to monitor key quality parameters and make adjustments as necessary.

- Continuous improvement: Regularly reviewing and optimizing the process to identify and address potential sources of variation.

4. Describe the troubleshooting process you follow when encountering issues during clay preparation?

My troubleshooting process includes:

- Identifying the issue: Clearly defining the problem and its symptoms.

- Gathering data: Collecting relevant information about the process, equipment, and materials.

- Analyzing root causes: Using data and observations to identify the underlying causes of the issue.

- Developing solutions: Generating and evaluating potential solutions to address the root causes.

- Implementing and monitoring: Implementing the chosen solution and monitoring its effectiveness to ensure the issue is resolved.

5. How do you optimize the efficiency of the clay preparation process?

To optimize efficiency, I focus on:

- Equipment maintenance: Ensuring that all equipment is regularly serviced and calibrated to minimize downtime.

- Process flow optimization: Analyzing and improving the flow of materials and equipment to reduce inefficiencies.

- Automation: Implementing automation technologies to streamline tasks and increase productivity.

- Employee training: Providing ongoing training to employees to enhance their skills and knowledge.

- Continuous improvement: Regularly reviewing and evaluating the process to identify areas for improvement.

6. How do you ensure the safety of the clay preparation process?

Safety is paramount, and I prioritize:

- Hazard identification: Identifying and assessing potential hazards associated with the process.

- Risk assessment: Evaluating the likelihood and severity of hazards to determine appropriate control measures.

- Safe work procedures: Developing and implementing clear and comprehensive safe work procedures.

- Employee training: Providing thorough safety training to all employees involved in the process.

- Regular inspections: Conducting regular inspections to ensure compliance with safety regulations and identify potential hazards.

7. Describe your experience in managing a team of clay preparation operators?

In my previous role, I was responsible for managing a team of clay preparation operators. My key responsibilities included:

- Team leadership: Motivating and guiding the team to achieve performance targets.

- Training and development: Providing training to enhance the skills and knowledge of the team.

- Performance evaluation: Regularly assessing and providing feedback on the performance of team members.

- Conflict resolution: Effectively resolving conflicts and maintaining a positive work environment.

- Continuous improvement: Working with the team to identify and implement process improvements.

8. How do you stay up-to-date with the latest advancements in clay preparation technology?

To stay current, I:

- Attend industry conferences and workshops: Participate in industry events to learn about new technologies and trends.

- Read technical publications: Regularly review journals and articles to stay informed about research and developments.

- Network with industry professionals: Engage with experts in the field to exchange knowledge and insights.

- Explore online resources: Utilize online platforms and databases to access up-to-date information.

- Attend training programs: Participate in training programs offered by equipment manufacturers and industry organizations.

9. How would you handle a situation where the clay preparation process is not meeting quality standards?

If quality standards are not met, I would:

- Investigate the issue: Determine the root cause of the quality deviations.

- Identify corrective actions: Develop and implement solutions to address the identified root causes.

- Monitor and adjust: Continuously monitor the process and make necessary adjustments to ensure consistent quality.

- Communicate with stakeholders: Keep relevant stakeholders informed about the issue and progress made towards resolving it.

- Document and learn: Document the issue, corrective actions taken, and lessons learned to prevent similar occurrences in the future.

10. What are your thoughts on the future of clay preparation technology?

The future of clay preparation technology is promising and I anticipate advancements in:

- Automation and optimization: Increased automation and use of sensors to optimize process efficiency and quality control.

- Advanced materials: Development of new clay-based materials with improved properties and applications.

- Sustainability: Focus on eco-friendly technologies that reduce energy consumption and waste generation.

- Data analytics: Utilization of data analytics to improve process control, predict maintenance needs, and optimize performance.

- Artificial intelligence: Integration of AI algorithms to enhance decision-making and troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clay Preparation Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clay Preparation Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clay Preparation Supervisor plays a crucial role in overseeing the efficient operation of clay preparation processes. Their primary duties involve:

1. Clay Preparation and Processing

Supervising and directing clay preparation operations, ensuring equipment runs smoothly and processes meet quality standards.

- Monitoring clay quality and making necessary adjustments to optimize processing.

- Collaborating with process engineers to improve clay preparation techniques.

2. Equipment and Maintenance

Maintaining and repairing clay preparation equipment, ensuring it operates effectively and safely.

- Scheduling regular maintenance and inspections to prevent breakdowns.

- Troubleshooting and resolving equipment malfunctions.

3. Production Management

Supervising and motivating a team of clay preparation operators, ensuring production targets are met and quality standards are maintained.

- Allocating tasks, monitoring progress, and providing feedback to operators.

- Implementing process improvements to enhance efficiency and quality.

4. Safety and Compliance

Ensuring adherence to safety regulations and environmental standards in the clay preparation area.

- conducting safety inspections and training sessions.

- Maintaining compliance with regulatory requirements and industry best practices.

Interview Tips

Preparing for an interview for a Clay Preparation Supervisor position requires a combination of technical knowledge and an understanding of the industry.

1. Research the Company and Industry

Thoroughly research the company and the clay preparation industry to demonstrate your interest and understanding.

- Review their website, annual reports, and industry news to gather information about their operations, products, and market position.

- Attend industry events or read trade publications to stay up-to-date on industry trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in clay preparation, process optimization, and equipment maintenance.

- Quantify your accomplishments using specific metrics to demonstrate your impact on production and quality.

- Provide examples of innovative solutions you have implemented or process improvements you have made.

3. Demonstrate Leadership and Management Abilities

Showcase your leadership and management abilities through your experience in supervising and motivating teams.

- Describe your strategies for team building, communication, and conflict resolution.

- Explain how you have fostered a positive and productive work environment in previous roles.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that align with the key responsibilities of the position.

- “Describe your experience in clay preparation and how you have optimized processes.” Answer with specific examples of process improvements and their impact on quality and efficiency.

- “How do you ensure the quality and consistency of clay preparation?” Explain your quality control procedures and how you monitor and adjust processes to maintain standards.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Clay Preparation Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Clay Preparation Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.