Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clean in Places Operator (CIP Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

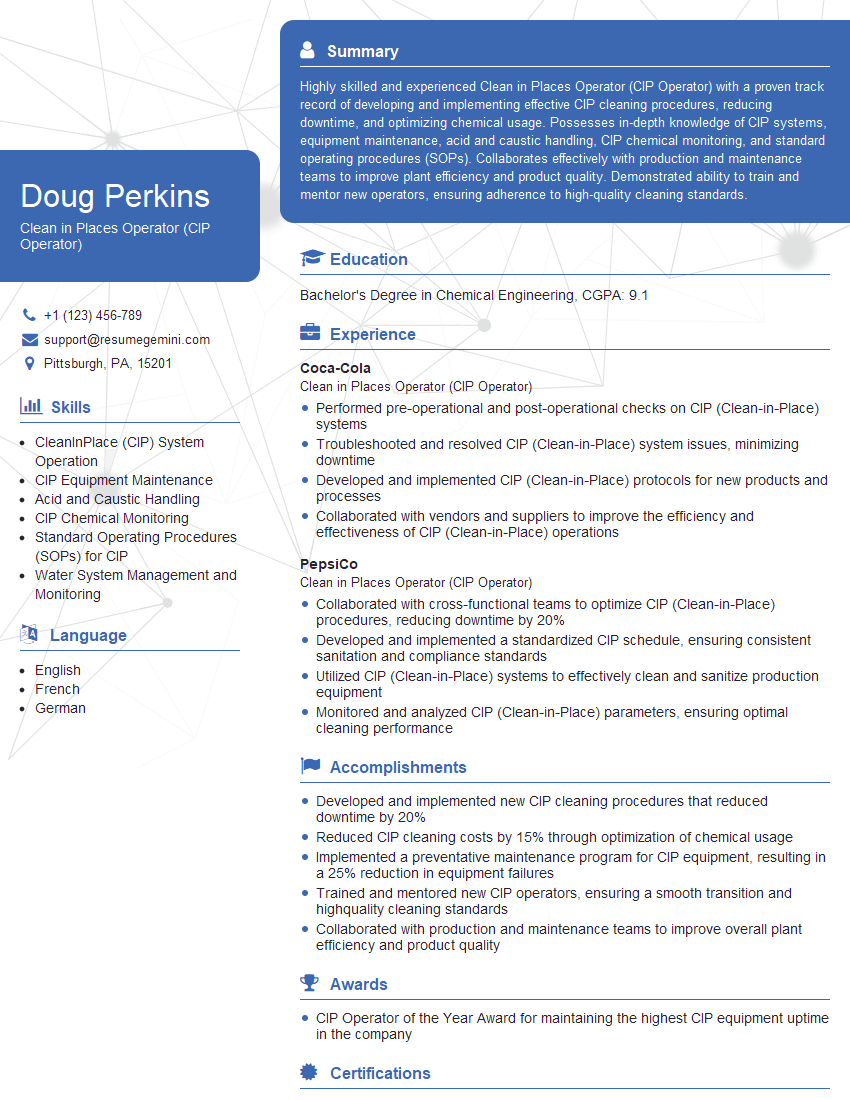

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clean in Places Operator (CIP Operator)

1. Describe the key responsibilities of a Clean in Places Operator (CIP)?

- Maintaining a clean and hygienic work environment within the production area

- Following established cleaning and sanitation procedures

- Inspecting and sanitizing equipment, machinery, and surfaces

- Monitoring and recording cleaning activities

- Adhering to safety protocols and regulations

2. Explain the importance of following CIP procedures and how it relates to product quality and safety?

Understanding CIP Procedures

- CIP procedures are meticulously designed to ensure the elimination of microorganisms and contaminants

- Proper execution of these procedures prevents product contamination and maintains hygiene

Consequences of Non-Compliance

- Failure to follow CIP procedures can lead to product spoilage, quality issues, and potential health hazards

- Maintaining the integrity of the production process is essential for consumer safety and regulatory compliance

3. What are the common cleaning agents and sanitizers used in CIP operations and how should they be handled?

- Cleaning Agents: Acids, alkalis, detergents, and solvents

- Sanitizers: Chlorine, quaternary ammonium compounds, hydrogen peroxide

- Handling Precautions:

- Wear appropriate protective gear (gloves, mask, safety glasses)

- Follow manufacturer’s instructions for dilution and application

- Store chemicals safely and dispose of them properly

4. Describe the use of specialized equipment for CIP operations, such as CIP carts and sprayers?

- CIP Carts: Mobile units that dispense cleaning and sanitizing solutions

- Ensure proper mixing and temperature of solutions

- Facilitate efficient cleaning of large surfaces

- Sprayers: Devices that apply cleaning solutions as a mist or foam

- Reach inaccessible areas and remove stubborn contaminants

- Rinse surfaces effectively

5. What is the importance of record-keeping in CIP operations?

- Documentation: Provides evidence of cleaning and sanitizing activities

- Traceability: Allows for identification of potential contamination sources

- Compliance: Meets regulatory requirements and ensures adherence to quality standards

- Continuous Improvement: Helps identify areas for improvement and optimize cleaning processes

6. Explain the role of maintenance in CIP operations and how it contributes to overall hygiene?

- Regular maintenance prevents equipment malfunctions and ensures proper functionality

- Inspecting seals, gaskets, and piping ensures there are no leaks or blockages

- Calibrating equipment ensures accurate dosing and application of cleaning solutions

7. Describe the safety precautions that must be taken when working with hazardous cleaning chemicals?

- Personal Protective Equipment (PPE): Use gloves, eye protection, and respirators as needed

- Proper Handling: Follow instructions for mixing, dilution, and disposal

- Ventilation: Ensure adequate ventilation to prevent exposure to fumes

- Emergency Response: Know the location of emergency showers and spill kits

- Training: Receive thorough training on chemical safety and handling

8. How do you ensure that all areas and equipment are thoroughly cleaned and sanitized?

- Systematic Approach: Follow established cleaning schedules and procedures

- Attention to Detail: Inspect all surfaces, including hidden areas and crevices

- Verification: Use visual inspection, swabs, or chemical indicators to confirm cleanliness

- Continuous Monitoring: Regularly check for areas that require additional attention

9. What steps should be taken in the event of a chemical spill or contamination?

- Immediate Response: Contain the spill and prevent it from spreading

- Notification: Inform supervisors and relevant authorities

- Clean-up: Use appropriate absorbents and cleaning agents to neutralize and remove the spill

- Disinfection: Sanitize the affected area to eliminate any remaining contaminants

- Documentation: Record the details of the incident and corrective actions taken

10. Explain the importance of teamwork and communication in maintaining a clean and hygienic work environment?

- Team Collaboration: Share responsibilities and support each other in maintaining cleanliness

- Effective Communication: Report any issues, concerns, or areas requiring attention promptly

- Training and Development: Ensure that all team members are trained and updated on cleaning procedures

- Continuous Improvement: Work together to identify potential risks and develop solutions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clean in Places Operator (CIP Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clean in Places Operator (CIP Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clean in Places (CIP) Operator is responsible for maintaining the cleanliness and sanitation of food processing equipment and facilities. Their key responsibilities include:

1. Equipment Cleaning and Sanitation

CIP Operators are responsible for cleaning and sanitizing all food processing equipment, including tanks, pipelines, valves, and other components. They use a variety of cleaning agents and sanitizers to ensure that the equipment is free of bacteria and other contaminants. They also follow established cleaning procedures and protocols to maintain the highest level of hygiene.

2. Facility Maintenance and Sanitation

In addition to cleaning equipment, CIP Operators are also responsible for maintaining the cleanliness and sanitation of the entire food processing facility. They sweep and mop floors, clean walls and ceilings, and disinfect surfaces to prevent the spread of bacteria. They also inspect and maintain drains and ventilation systems to ensure that they are functioning properly.

3. Monitoring and Record Keeping

CIP Operators monitor the cleaning and sanitation process and keep detailed records of all activities. They document the cleaning agents and sanitizers used, the cleaning procedures followed, and the results of inspections. These records are used to ensure that the facility is meeting all regulatory requirements and maintaining the highest standards of hygiene.

4. Troubleshooting and Problem Solving

CIP Operators are often responsible for troubleshooting and solving problems related to cleaning and sanitation. They may need to identify the source of contamination, develop and implement corrective actions, and make recommendations for improving cleaning procedures. They also work with other departments, such as maintenance and engineering, to resolve issues that affect the cleanliness and sanitation of the facility.

Interview Tips

To ace an interview for a CIP Operator position, follow these tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific CIP Operator position you are applying for. This will help you understand the company’s culture, values, and expectations for the role. You can find information on the company’s website, social media pages, and industry publications.

2. Practice Your Answers

Once you have a good understanding of the company and the position, practice answering common interview questions. This will help you feel more confident and prepared during the interview. Some common questions you may be asked include:

- Tell me about your experience in cleaning and sanitation.

- What are your knowledge of food safety and regulatory requirements?

- How do you troubleshoot and solve problems related to cleaning and sanitation?

- What are your strengths and weaknesses as a CIP Operator?

- Why are you interested in working for this company?

3. Prepare Questions to Ask

At the end of the interview, you will likely be given the opportunity to ask questions. This is your chance to learn more about the company and the position and to show the interviewer that you are interested and engaged. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

- Do you have any concerns about my qualifications for this position?

4. Be Professional and Enthusiastic

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, and maintain a positive attitude throughout the interview. Show the interviewer that you are enthusiastic about the position and that you are confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clean in Places Operator (CIP Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!