Feeling lost in a sea of interview questions? Landed that dream interview for Clean-Out Driller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Clean-Out Driller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

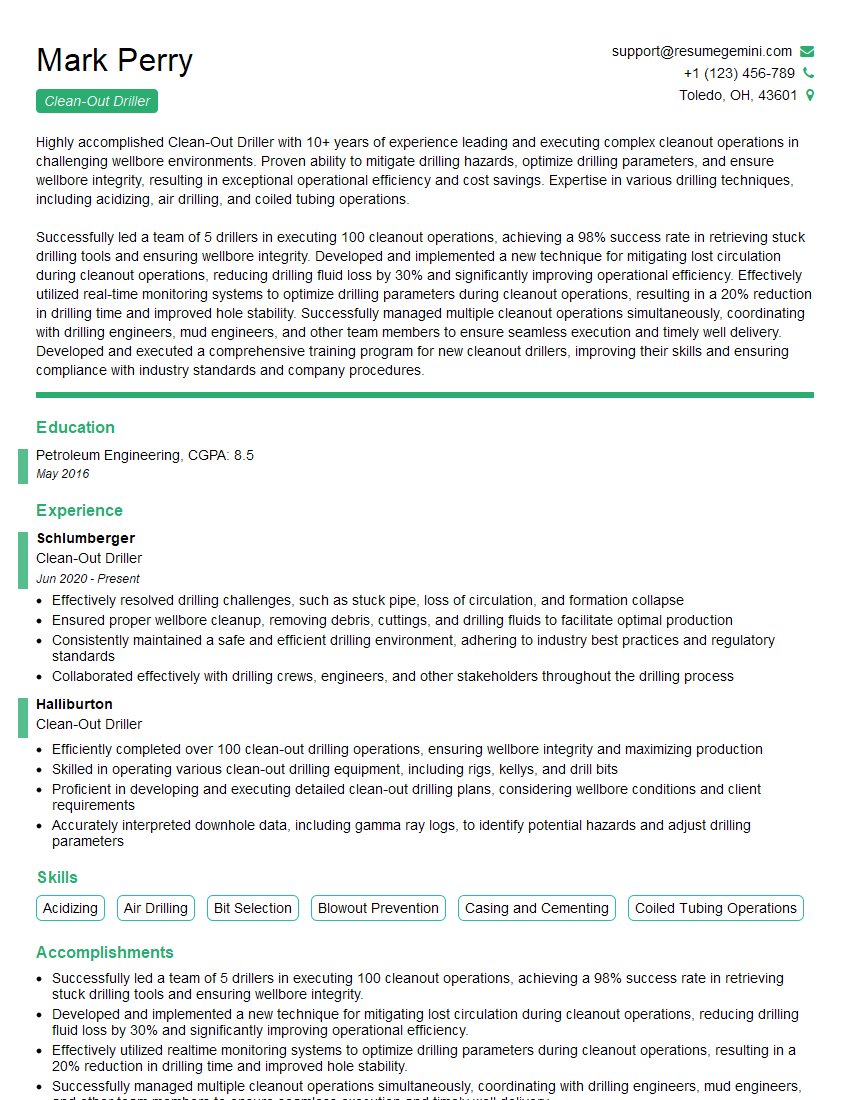

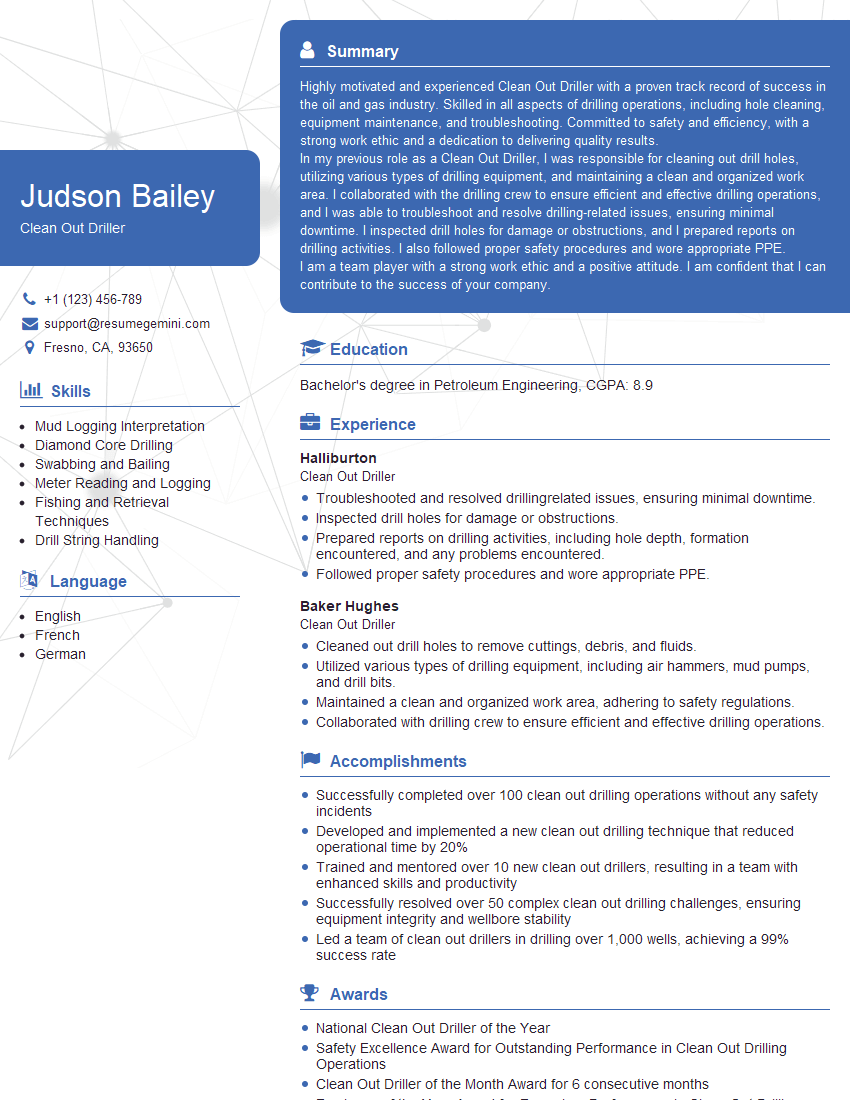

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clean-Out Driller

1. Describe your experience in drilling deep wells for oil and gas production?

In my previous role as a Clean-Out Driller, I was responsible for drilling deep wells up to 15,000 feet for oil and gas production. I have extensive experience in operating and maintaining drilling equipment, including rotary rigs, mud pumps, and blowout preventers.

2. What are the key safety considerations when drilling deep wells?

Safety is paramount when drilling deep wells. Some key considerations include:

Well Control:

- Maintaining wellbore pressure within safe limits

- Using blowout preventers and other equipment to prevent uncontrolled flow of fluids

Equipment Inspection and Maintenance:

- Regularly inspecting and maintaining drilling equipment to ensure it is in safe working order

- Following manufacturer’s guidelines for equipment operation and maintenance

Personnel Training and Certification:

- Ensuring that all personnel are properly trained and certified in safe drilling practices

- Conducting regular safety meetings and drills to reinforce training

3. How do you handle unexpected situations that arise during drilling operations?

Unexpected situations are common in drilling operations. I remain calm and assess the situation, then develop a plan to address the issue safely and efficiently. For example, if I encounter lost circulation, I may adjust the drilling fluid properties or use lost circulation materials to seal off the lost zone.

4. What are the different types of drilling fluids used, and how do you select the appropriate fluid for a given drilling scenario?

There are several types of drilling fluids, each with its own properties and applications. Some common types include:

- Water-based muds: Used in stable formations with minimal reactivity

- Oil-based muds: Used in reactive formations or where high temperatures are encountered

- Synthetic-based muds: Offer a balance of properties, including high lubricity and thermal stability

The selection of the appropriate drilling fluid depends on factors such as formation characteristics, well depth, and environmental regulations.

5. How do you monitor and evaluate drilling performance to optimize efficiency?

I regularly monitor drilling parameters such as rate of penetration, torque, and mud properties. I analyze this data to identify areas for improvement and adjust drilling parameters accordingly. For example, if I am experiencing slow penetration, I may increase the weight on bit or optimize the mud properties to reduce friction.

6. What are the environmental regulations and industry best practices related to drilling operations, and how do you ensure compliance?

I am familiar with environmental regulations and industry best practices related to drilling operations. I diligently follow these regulations and practices to protect the environment and ensure the safe and responsible conduct of drilling activities. For example, I ensure proper handling and disposal of drilling fluids and cuttings, and minimize emissions by maintaining efficient combustion in drilling equipment.

7. How do you work effectively as part of a drilling team?

I am a team player and have a strong work ethic. I communicate effectively with other team members, including engineers, geologists, and rig crew, to ensure a smooth and coordinated drilling operation. I am also willing to share my knowledge and expertise to support the team’s goals.

8. Describe your experience with directional drilling and the techniques used to control wellbore trajectory?

I have experience in directional drilling, which involves controlling the direction of the wellbore to reach specific targets or avoid obstacles. I am familiar with techniques such as downhole motors, steerable tools, and mud motors. I have used these techniques to successfully drill deviated and horizontal wells.

9. How do you prepare for and execute a wellbore cleanout operation?

To prepare for a wellbore cleanout operation, I review well data and select the appropriate downhole tools and equipment. I also coordinate with rig personnel and other team members to ensure a safe and efficient operation. During execution, I monitor equipment performance and make adjustments as needed. I also ensure proper handling and disposal of the removed debris.

10. What are the different wellbore cleanout methods, and when are they used?

Common wellbore cleanout methods include:

- Mechanical cleaning: Using tools like scrapers and brushes to remove debris

- Chemical cleaning: Using solvents or acids to dissolve and dislodge scale or other deposits

- Jet cleaning: Using high-pressure water or other fluids to remove debris

The choice of method depends on the type and severity of the debris, the wellbore conditions, and the production requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clean-Out Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clean-Out Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Clean-Out Driller

A Clean-Out Driller plays a crucial role in oil and gas drilling operations by ensuring the final cleanup of a well after drilling and before production.

1. Well Cleanout and Preparation

The primary responsibility of a Clean-Out Driller involves removing cuttings, debris, and fluids from the wellbore after the primary drilling process.

- Operating drilling equipment to clear the wellbore, circulate drilling fluids, and maintain wellbore stability

- Monitoring drilling parameters and adjusting equipment settings to optimize cleaning efficiency

2. Hole Conditioning

The driller is responsible for conditioning the wellbore to prepare it for production or further drilling operations.

- Maintaining proper drilling fluid properties and circulation rates to remove contaminants

- Ensuring the wellbore is in good condition, free from any obstructions or damage

3. Equipment Maintenance and Troubleshooting

As part of the job, the Clean-Out Driller is involved in the maintenance and troubleshooting of drilling equipment.

- Inspecting and servicing drilling equipment, including blowout preventers, pumps, and drilling rigs

- Troubleshooting and resolving any equipment malfunctions or technical difficulties

4. Safety and Compliance

The role of a Clean-Out Driller places significant emphasis on safety and compliance.

- Adhering to safety protocols and regulations, including wearing protective gear and following established procedures

- Maintaining a clean and orderly work environment, ensuring compliance with environmental regulations

Interview Tips for Clean-Out Drillers

To ace the interview for a Clean-Out Driller position, it is essential to prepare thoroughly and present yourself in the best possible light.

1. Research the Company and Position

Study the company’s profile, their operations, and any specific requirements for the Clean-Out Driller position. This will allow you to align your answers with the company’s needs.

2. Practice Your Answers

Anticipate common interview questions related to your skills, experience, and knowledge of the oil and gas industry. Practice your answers to demonstrate your proficiency in clean-out drilling operations.

3. Highlight Your Experience and Skills

Emphasize your relevant work experience, especially in drilling and clean-out operations. Showcase your skills in operating drilling equipment, maintaining wellbore stability, and troubleshooting equipment malfunctions.

4. Demonstrate Safety Awareness

Stress your commitment to safety and your adherence to established safety protocols. Explain your understanding of the hazards associated with drilling operations and your strategies for mitigating risks.

5. Show Your Enthusiasm and Learning Mindset

Express your enthusiasm for the Clean-Out Driller role and your eagerness to contribute to the team. Demonstrate your willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clean-Out Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!