Are you gearing up for a career in Clicking Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Clicking Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

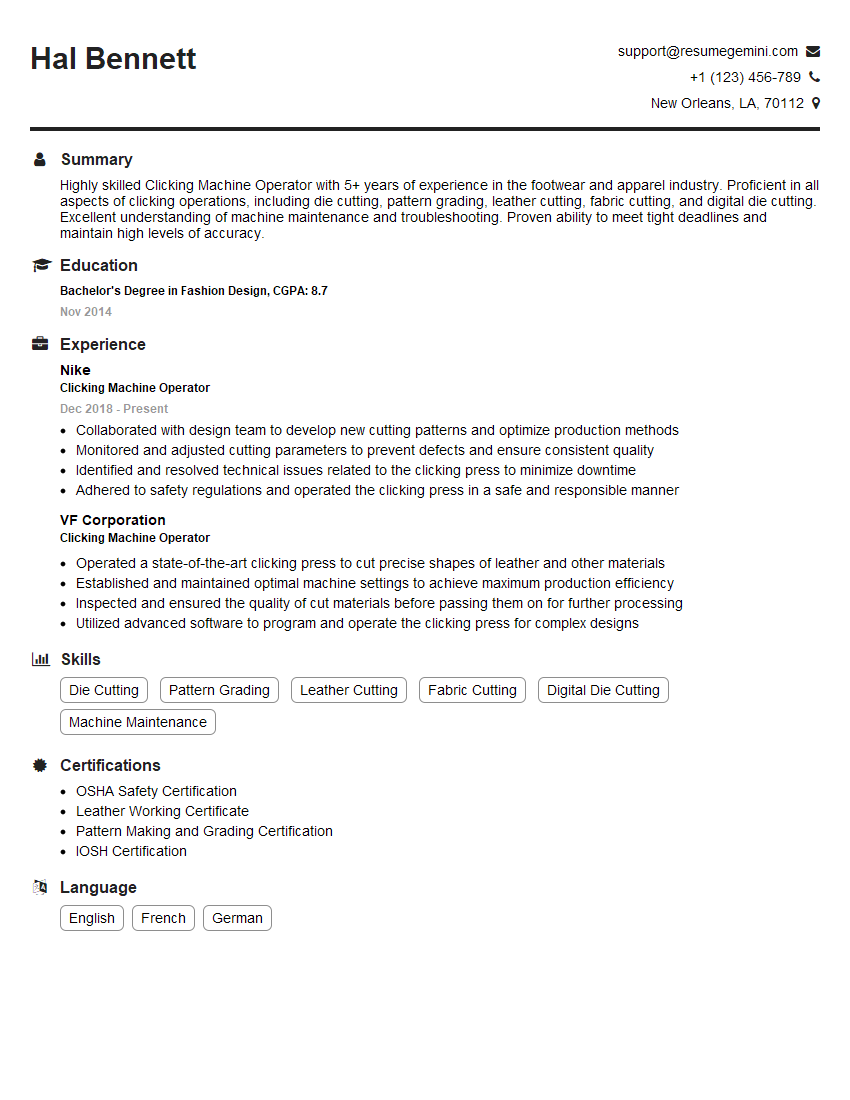

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clicking Machine Operator

1. What are the different types of clicking machines and their uses?

- Hydraulic clicking machine: This type of clicking machine uses hydraulic pressure to cut through the material. It is suitable for cutting thick and tough materials such as leather and rubber.

- Electric clicking machine: This type of clicking machine uses an electric motor to power the cutting blade. It is suitable for cutting thin and delicate materials such as fabrics and plastics.

- Mechanical clicking machine: This type of clicking machine uses a mechanical linkage to power the cutting blade. It is suitable for cutting materials of various thicknesses and hardness.

2. How do you set up and operate a clicking machine?

Setting up the machine

- Mount the cutting die on the machine bed.

- Adjust the cutting height and pressure.

- Load the material onto the machine table.

Operating the machine

- Start the machine and feed the material through the cutting die.

- Monitor the cutting process and make adjustments as needed.

- Stop the machine when the cutting is complete.

3. What are the safety precautions that must be taken when operating a clicking machine?

- Always wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Never operate the machine when it is not properly set up and guarded.

- Keep the work area clean and free of debris.

- Never reach into the cutting area while the machine is running.

- Follow all manufacturer’s instructions for safe operation.

4. How do you troubleshoot common problems that occur with clicking machines?

- The machine is not cutting through the material:

- Check the cutting die for damage.

- Adjust the cutting height and pressure.

- Sharpen or replace the cutting blade.

- The machine is making a lot of noise:

- Check for loose bolts or screws.

- Lubricate the moving parts.

- Contact the manufacturer for support.

- The machine is vibrating excessively:

- Check for unbalanced cutting die.

- Adjust the machine feet to level it.

- Contact the manufacturer for support.

5. What are the different types of materials that can be cut with a clicking machine?

- Leather

- Rubber

- Fabrics

- Plastics

- Paperboard

6. What are the key factors that affect the quality of the cut made by a clicking machine?

- The sharpness of the cutting die

- The cutting height and pressure

- The speed of the machine

- The type of material being cut

- The condition of the machine

7. How do you maintain a clicking machine to ensure optimal performance?

- Clean the machine regularly.

- Lubricate the moving parts.

- Inspect the cutting die for damage.

- Sharpen or replace the cutting blade as needed.

- Follow all manufacturer’s instructions for maintenance.

8. What are the different types of cutting dies that can be used with a clicking machine?

- Steel rule dies

- Solid steel dies

- Laser dies

- Waterjet dies

9. How do you choose the right cutting die for a particular application?

- Consider the type of material being cut.

- Consider the thickness of the material.

- Consider the desired cut quality.

- Consider the cost of the die.

10. What are the advantages of using a clicking machine over other cutting methods?

- Clicking machines are fast and efficient.

- Clicking machines produce clean and precise cuts.

- Clicking machines can be used to cut a variety of materials.

- Clicking machines are relatively easy to operate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clicking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clicking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operating and maintaining clicking machines

Clicking machine operators are responsible for operating and maintaining clicking machines. These machines are used to cut shapes out of various materials, such as leather, fabric, and rubber. Operators must be able to set up and operate the machines correctly, and they must be able to troubleshoot any problems that may arise.

2. Loading and unloading materials

Operators are also responsible for loading and unloading materials into and out of the machines. They must be able to handle these materials safely and efficiently, and they must be able to identify any defects in the materials.

3. Inspecting products

Operators are responsible for inspecting the products that are produced by the machines. They must be able to identify any defects in the products, and they must be able to make sure that the products meet the required specifications.

4. Maintaining a clean and safe work area

Operators are responsible for maintaining a clean and safe work area. They must be able to clean and maintain the machines, and they must be able to identify and устранить any potential hazards.

Interview Tips

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your work history and your educational background. Be sure to highlight any skills or experience that are relevant to the position you are applying for.

4. Ask questions

Asking questions at the end of an interview shows that you are interested in the position and that you are taking the interview seriously. It also gives you an opportunity to learn more about the company and the position.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position and that you are eager to learn more. You can follow up by sending a thank-you note or by calling the interviewer to ask if they have any further questions.

Example Interview Outline:

1. Tell me about yourself.

2. Why are you interested in this position?

3. What are your strengths and weaknesses?

4. What are your salary expectations?

5. What are your career goals?

6. Do you have any questions for me?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clicking Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.