Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clip Loading Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

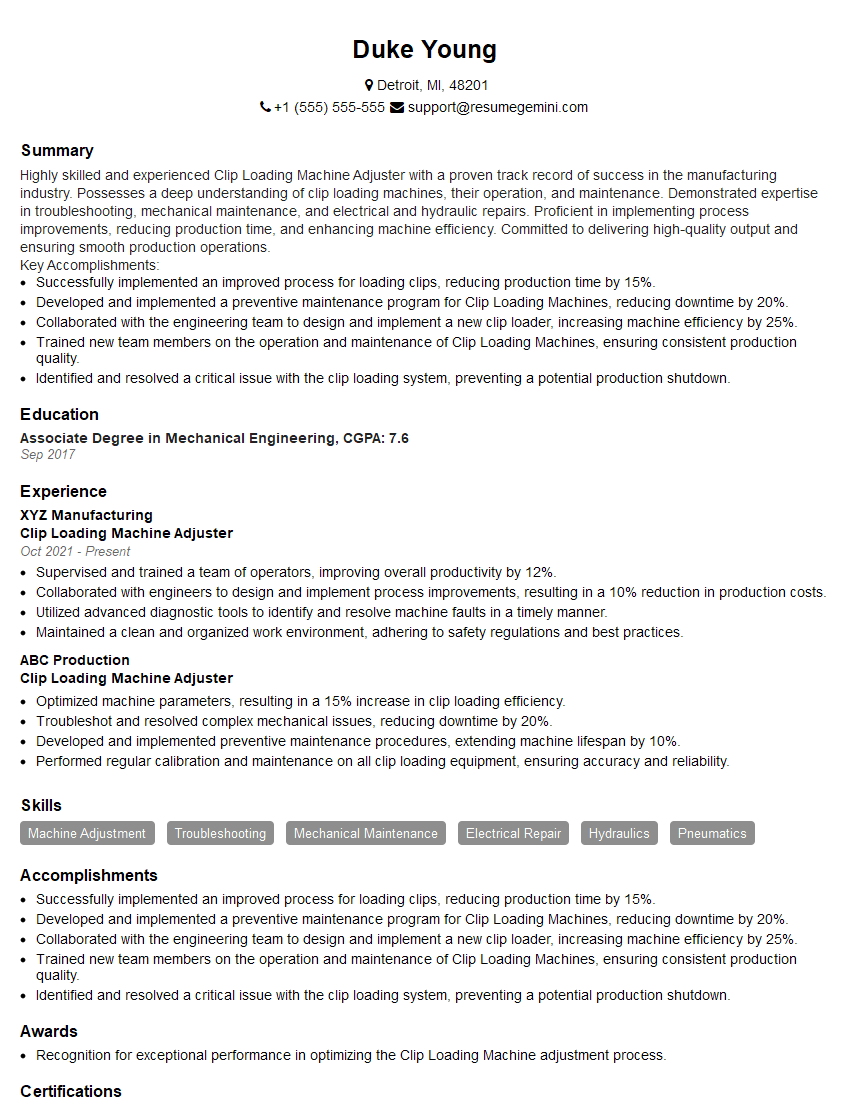

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clip Loading Machine Adjuster

1. Describe the primary responsibilities of a Clip Loading Machine Adjuster?

As a Clip Loading Machine Adjuster, my key responsibilities include:

- Setting up, adjusting, and maintaining clip loading machines to ensure optimal performance

- Calibrating and aligning machine components, such as sensors, conveyors, and dispensers

- Monitoring machine operation, identifying and troubleshooting malfunctions

- Performing preventative maintenance and repairs to keep machines in top condition

- Collaborating with production teams to optimize production efficiency and meet quality standards

2. Explain the process of fine-tuning a clip loading machine for optimal performance?

Calibrating Sensors

- Check sensor alignment and distance from the target

- Adjust sensor sensitivity to accurately detect clips

Fine-tuning Conveyors

- Adjust conveyor speed and tension to ensure smooth clip feeding

- Check conveyor alignment to prevent jamming

Optimizing Dispenser Settings

- Set precise clip spacing and orientation parameters

- Monitor adhesive application and adjust settings to ensure proper bonding

3. How do you handle complex machine breakdowns and malfunctions?

When faced with complex machine breakdowns, I follow a structured approach:

- Identify the symptoms and potential causes

- Consult technical documentation and consult with senior technicians

- Systematically isolate and test components

- Replace or repair faulty parts using manufacturer-approved procedures

- Thoroughly test the machine to ensure it is functioning properly

4. Describe your experience with PLC programming and troubleshooting?

I am proficient in PLC programming using languages such as Ladder Logic and Structured Text. I have experience in:

- Developing, modifying, and debugging PLC programs for clip loading machines

- Troubleshooting PLC-related issues, such as communication errors and logic faults

- Optimizing PLC code for enhanced machine efficiency and reliability

5. Explain how you ensure the accuracy and consistency of clip placement?

To ensure accuracy and consistency in clip placement, I:

- Calibrate machine sensors to detect clips precisely

- Set and verify machine parameters, such as clip spacing and orientation

- Monitor production samples and make adjustments as needed

- Perform regular maintenance and calibration to minimize drift and ensure ongoing accuracy

6. How do you prioritize your workload and manage time effectively?

I effectively prioritize my workload and manage time through the following strategies:

- Asses the urgency and importance of tasks

- Create a prioritized list and allocate time accordingly

- Break down complex tasks into smaller, manageable steps

- Use productivity tools and techniques, such as task management apps

- Communicate with supervisors and team members to coordinate schedules

7. What safety precautions do you observe when working with clip loading machines?

I strictly adhere to established safety protocols when working with clip loading machines:

- Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves

- Ensure the machine is properly grounded and shielded

- Follow lockout/tagout procedures during maintenance

- Inspect the machine for any potential hazards or unsafe conditions

- Report and address any safety concerns promptly

8. Describe your experience with lean manufacturing principles and how you applied them in your previous role?

I am familiar with lean manufacturing principles and have actively applied them in my previous role:

- Identified and eliminated waste in production processes

- Streamlined material flow and reduced setup times

- Optimized machine utilization and increased production efficiency

- Improved communication and collaboration among team members

- Reduced defects and improved product quality

9. How do you stay updated with the latest technologies and industry best practices?

To stay abreast of industry developments, I:

- Attend industry conferences and workshops

- Read technical journals and trade publications

- Participate in online forums and discussion groups

- Collaborate with colleagues and industry experts

- Take advantage of training opportunities provided by my employer

10. What are your career goals and how does this position align with them?

My career goal is to become a highly skilled and experienced Automation Technician with a focus on maintaining and improving the efficiency of manufacturing processes. I believe that this position aligns well with my aspirations because it offers me the opportunity to:

- Utilize my technical skills to optimize clip loading machines

- Collaborate with a team of engineers and technicians to drive continuous improvement

- Contribute to the overall success and productivity of the manufacturing operation

- Gain valuable experience that will support my career growth

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clip Loading Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clip Loading Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Clip Loading Machine Adjusters are responsible for maintaining and adjusting clip loading machines to ensure smooth production. Their key responsibilities include:

1. Machine Operation and Maintenance

Operate and monitor clip loading machines to ensure efficient operation.

- Adjust machine settings to optimize performance and production output.

- Conduct preventive maintenance and repairs to minimize downtime and ensure machine reliability.

2. Troubleshooting and Problem Solving

Identify and resolve technical issues with clip loading machines.

- Diagnose mechanical, electrical, and software problems.

- Repair or replace faulty components to maintain machine functionality.

3. Quality Control and Inspection

Monitor machine output and ensure that clip loading meets quality standards.

- Inspect clips for defects and ensure proper loading.

- Calibrate and verify measuring instruments to ensure accuracy.

4. Collaboration and Communication

Communicate effectively with production personnel, maintenance technicians, and supervisors.

- Provide training and support to operators on machine operation and maintenance.

- Report machine performance and any issues to relevant stakeholders.

Interview Tips

To ace your interview for a Clip Loading Machine Adjuster position, consider these preparation tips:

1. Research the Company and Position

- Thoroughly review the company’s website, social media, and industry news to understand their business, products, and culture.

- Research the specific responsibilities and qualifications of the Clip Loading Machine Adjuster role to tailor your answers accordingly.

2. Highlight Relevant Skills and Experience

- Emphasize your technical skills in machine operation, maintenance, and troubleshooting.

- Quantify your achievements and provide specific examples of how you have improved machine efficiency or resolved complex problems.

3. Demonstrate Problem-Solving Ability

- Prepare for technical questions related to machine operation and troubleshooting.

- Use the STAR method (Situation, Task, Action, Result) to describe how you have successfully diagnosed and resolved machine issues in the past.

4. Showcase Attention to Detail

- Highlight your ability to identify and correct even minor defects in clip loading.

- Explain your proficiency in using measuring instruments and maintaining quality standards.

5. Emphasize Communication and Teamwork

- Describe your experience working in a team environment and communicating effectively with colleagues.

- Explain how you have successfully resolved issues and provided support to others in a production setting.

Next Step:

Now that you’re armed with the knowledge of Clip Loading Machine Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Clip Loading Machine Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini