Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clipper and Turner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

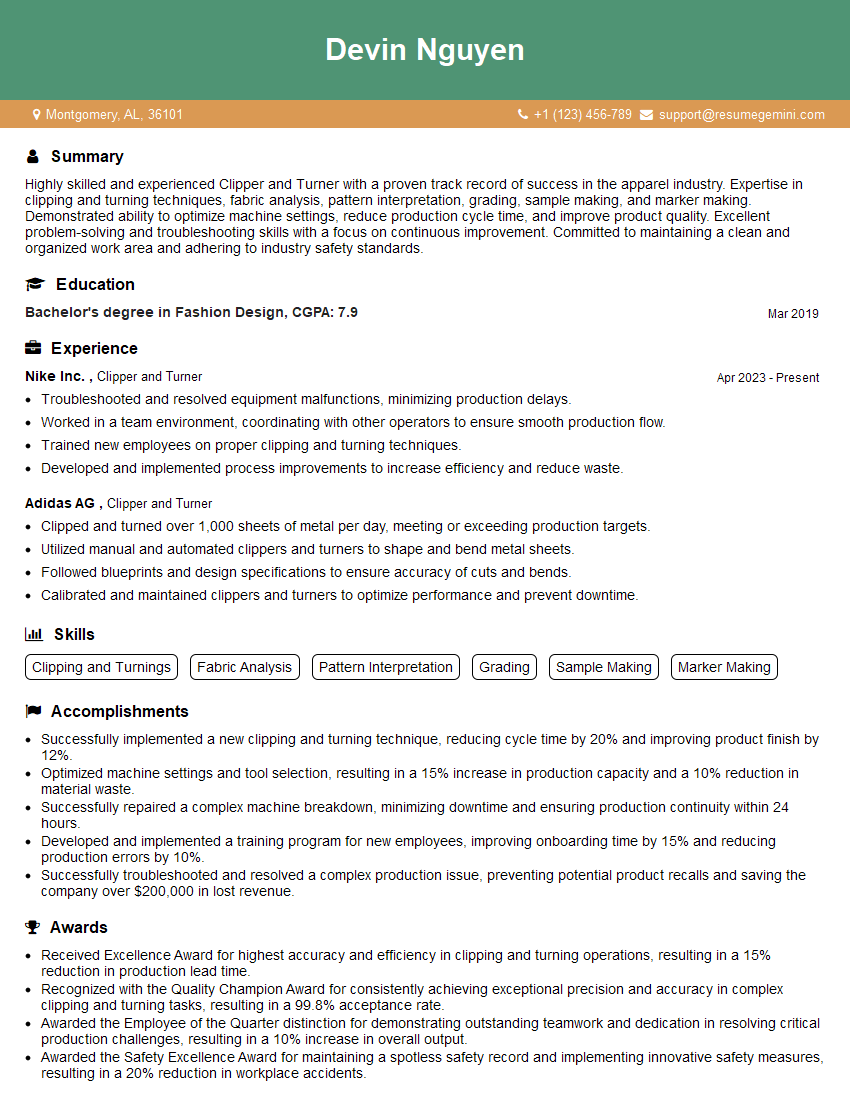

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clipper and Turner

1. What is the purpose of thread tension in clipper?

Thread tension in a clipper is crucial for ensuring proper functioning and the desired quality of the cut. It involves adjusting the amount of tension applied to the thread, which affects its tightness and strength.

- Optimal Tension: Proper tension ensures that the thread is neither too loose (resulting in poor cutting performance) nor too tight (causing thread breakage or damage to the material being cut).

- Thread Type: Different thread types have varying tension requirements. Knowing the appropriate tension settings for the specific thread being used is essential.

- Material Thickness: The thickness of the material being cut also influences the necessary thread tension. Thicker materials require higher tension to achieve clean and effective cuts.

2. Explain the importance of blade sharpness in a clipper and how it affects cutting performance.

- Precise Cuts: Sharp blades ensure clean and precise cuts, reducing the risk of snagging or tearing the material.

- Optimal Cutting Speed: Sharp blades facilitate a faster and more efficient cutting process, saving time and effort.

- Blade Life: Properly sharpened blades last longer, reducing downtime and maintenance costs.

3. How do you troubleshoot a clipper that is not cutting properly?

There are several potential causes for a clipper not cutting properly, and the troubleshooting process involves identifying and addressing each possibility systematically.

- Blade Sharpness: Check if the blades are sharp and free of any nicks or damage.

- Thread Tension: Ensure that the thread tension is set correctly for the material being cut.

- Clipper Lubrication: Insufficient lubrication can cause friction and hinder the clipper’s performance. Apply a small amount of clipper oil to the moving parts.

- Electrical Connections: Check if the clipper is receiving adequate power. Loose or faulty electrical connections can disrupt its operation.

4. Describe the different types of clipper blades and their specific applications.

- Fine-tooth Blades: Used for precision cutting, such as fades, tapers, and close shaving, due to their ability to create short and even cuts.

- Medium-tooth Blades: Versatile blades suitable for general-purpose cutting and blending. They offer a balance between precision and speed.

- Coarse-tooth Blades: Designed for cutting thick or unruly hair. Their wider spacing allows for bulk removal of hair, making them well-suited for clipper-over-comb techniques.

5. How do you maintain and clean Clipper and Turner clippers to ensure optimal performance and longevity?

- Blade Maintenance: Regularly clean the blades with a brush to remove any hair or debris. Lubricate the blades after each use to reduce friction and wear.

- Housing Cleaning: Clean the clipper housing using a damp cloth and disinfectant to prevent the accumulation of hair and dirt. Avoid using excessive moisture to prevent damage to electrical components.

- Electrical Care: Inspect the electrical cord and connections for any signs of damage. Store the clipper in a dry and protected place when not in use.

6. Explain the role of guide combs in clipper use and describe the different types available.

- Length Control: Guide combs allow barbers to control the length of the hair being cut, enabling them to achieve desired hairstyles and fades.

- Variety of Sizes: Guide combs come in various sizes, ranging from short (e.g., 1/16 inch) to long (e.g., 1 inch), catering to different hair lengths and styles.

- Clipper Attachment: Guide combs attach to the clipper’s blade and slide over the hair, ensuring that only hair protruding beyond the comb’s teeth is cut.

7. Describe the techniques involved in clipper-over-comb cutting and blending.

- Clipper-over-Comb Cutting: Involves holding the clipper parallel to the scalp and sliding the guide comb over the hair to remove bulk and create even lengths.

- Blending: A technique used to create smooth transitions between different hair lengths. Barbers hold the clipper at an angle and use the guide comb to gradually blend longer hair into shorter hair.

8. What is the importance of ergonomics in clipper design and how does it impact user comfort and efficiency?

- Comfort: Ergonomic clippers are designed to reduce strain on the user’s hand and wrist, ensuring comfort during prolonged use.

- Precision: Proper ergonomics allows for better control over the clipper, leading to more precise cuts and increased efficiency.

- Reduced Fatigue: Ergonomic clippers minimize muscle fatigue, enabling barbers to work for extended periods without discomfort.

9. Explain the different types of clippers available in the market and their intended applications.

- Corded Clippers: Provide uninterrupted power and are typically preferred for heavy-duty use in salons and barbershops.

- Cordless Clippers: Offer portability and flexibility, making them suitable for mobile barbers or home use.

- Rotary Clippers: Feature a rotating blade system and are known for their power and efficiency.

- Pivot Clippers: Equipped with a pivoting blade that conforms to the contours of the head, allowing for versatile cutting.

10. Discuss the safety precautions that should be observed when using clippers to ensure the safety of both the barber and the client.

- Sharp Blades: Handle clipper blades with care to avoid cuts and injuries.

- Electrical Safety: Ensure proper electrical connections and avoid using damaged cords or clippers.

- Hygiene: Regularly clean and disinfect clippers to prevent the spread of bacteria or infections.

- Proper Technique: Use clippers correctly to minimize the risk of snagging or cutting the client’s skin.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clipper and Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clipper and Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary role of a Clipper and Turner is to transform raw leather into finished leather goods, ensuring precise cutting and shaping to meet design specifications. This multifaceted position involves a comprehensive range of duties, including:

1. Cutting and shaping leather

Utilizing sharp cutting tools, clippers meticulously cut leather pieces based on patterns or diagrams, maintaining precision and accuracy to achieve optimal fit and appearance.

2. Stitching and assembling leather components

Skilled turners stitch and assemble leather components using specialized sewing machines, ensuring durability and flawless craftsmanship. They meticulously follow design specifications, paying attention to details such as seam allowances.

3. Inspecting finished products

To maintain high production standards, clippers and turners thoroughly inspect finished leather goods for any imperfections or errors. They assess the quality of cuts, stitching, and overall workmanship, ensuring that products meet the required specifications.

4. Operating and maintaining machinery

Efficient operation and maintenance of cutting, stitching, and other specialized machinery are critical for smooth production. Clippers and turners are responsible for ensuring that equipment functions properly, conducting routine maintenance, and identifying any potential issues promptly.

Interview Tips

To excel in an interview for the role of Clipper and Turner, meticulous preparation is essential. Here are some tips to help you ace the interview:

1. Research the company and industry

Demonstrating your understanding of the company’s culture, values, and industry trends will impress the interviewers. Research the company’s website, social media pages, and industry publications to gain insights.

2. Highlight your skills and experience

Tailor your resume and interview answers to emphasize your key skills and experience relevant to the position. Quantify your accomplishments whenever possible, using specific examples and metrics.

3. Showcase your attention to detail

The ability to pay meticulous attention to detail is crucial for a Clipper and Turner. Provide specific examples in your interview that demonstrate your accuracy and commitment to delivering high-quality work.

4. Prepare for technical questions

Expect to be asked technical questions about leather cutting, stitching techniques, and machinery operation. Practice answering these questions clearly and confidently, drawing upon your practical experience.

5. Ask thoughtful questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare a few insightful questions that show you are genuinely interested in the company and industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Clipper and Turner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.