Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Closing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

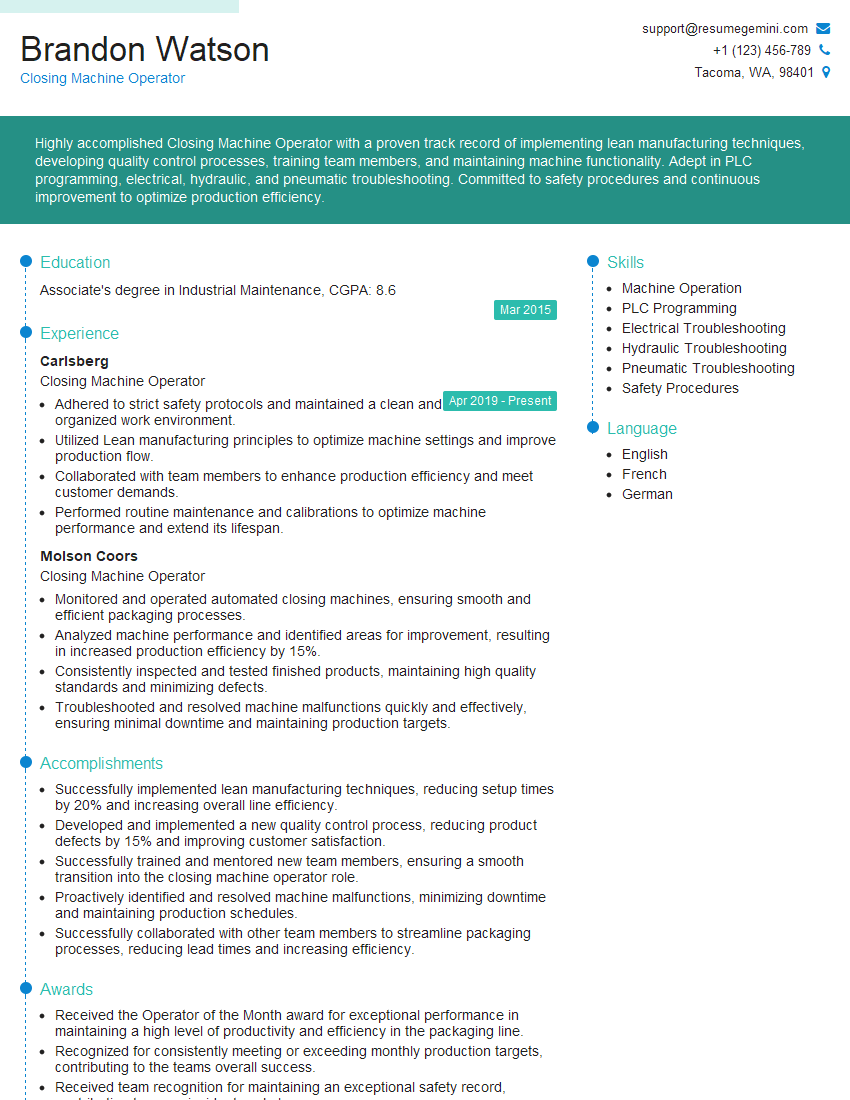

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Closing Machine Operator

1. Describe the key responsibilities of a Closing Machine Operator?

As a Closing Machine Operator, my primary responsibilities include:

- Operating and maintaining automated closing machines to seal and package various products and materials.

- Loading machines with proper packaging materials and ensuring smooth product flow.

- Monitoring machines to ensure proper operation, identify and resolve any issues promptly.

- Performing quality control checks to ensure products meet specifications and standards.

- Maintaining a clean and organized work area to promote efficiency and safety.

2. Explain the different types of closing machines you have operated and their applications?

I have experience operating various types of closing machines, including:

Shrink Wrapping Machines:

- Used to wrap products in a heat-shrinkable plastic film for protection and tamper resistance.

- Applications include packaging food, beverages, electronics, and industrial components.

Case Sealers:

- Designed to seal and close corrugated boxes used for shipping and storage.

- Applications include packaging appliances, furniture, and construction materials.

Bag Sealers:

- Used to seal and close bags made of various materials, such as plastic, paper, or foil.

- Applications include packaging food, medical supplies, and pharmaceuticals.

3. What are the common maintenance procedures you perform on closing machines?

Regular maintenance is crucial to ensure optimal machine performance. I typically perform the following tasks:

- Lubricating moving parts to reduce friction and wear.

- Inspecting and replacing worn or damaged parts, such as belts, seals, and bearings.

- Cleaning machines thoroughly to remove dust, debris, and product residue.

- Calibrating and adjusting machines to ensure accurate and consistent operation.

- Troubleshooting and resolving common machine issues.

4. How do you maintain product quality while operating closing machines?

Product quality is paramount. I employ several strategies to ensure standards are met:

- Following established operating procedures and specifications.

- Visually inspecting products before and after sealing to identify any defects or irregularities.

- Using quality control tools, such as gauges and meters, to verify product dimensions, weight, and other specifications.

- Working closely with quality assurance personnel to monitor and improve product quality.

- Maintaining a clean and organized work area to minimize contamination.

5. What safety measures do you observe while working with closing machines?

The safety of myself and others is a top priority. I adhere to the following safety measures:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Keeping work areas clear of obstacles and debris to prevent accidents.

- Being aware of the location of emergency stops and knowing how to use them.

- Reporting any unsafe conditions or practices to supervisors immediately.

6. Describe your experience with different packaging materials and their suitability for various products?

I have worked with a range of packaging materials, each with its unique properties and applications:

- Polyethylene (PE): Flexible and moisture-resistant, suitable for packaging food, beverages, and electronics.

- Polypropylene (PP): Durable and heat-resistant, used for packaging chemicals, pharmaceuticals, and automotive parts.

- Polyvinyl chloride (PVC): Rigid and tamper-proof, ideal for packaging toys, hardware, and construction materials.

- Corrugated cardboard: Provides cushioning and protection, used for shipping and storage of fragile items.

- Paper bags: Sustainable and biodegradable, suitable for packaging food, apparel, and cosmetics.

7. How do you handle production bottlenecks and ensure timely completion of orders?

Production bottlenecks can occur due to various factors. I address them efficiently by:

- Identifying the root cause of the bottleneck, such as machine issues, material shortages, or staffing problems.

- Communicating with supervisors and colleagues to find solutions and allocate resources.

- Prioritizing orders and adjusting production schedules to meet deadlines.

- Implementing process improvements to optimize machine performance and reduce downtime.

- Working overtime or adjusting shifts as needed to ensure timely order completion.

8. How do you stay up-to-date with advancements in closing machine technology?

To stay current with industry advancements, I:

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Read trade publications and technical articles to stay informed about the latest developments.

- Network with other professionals in the field to exchange knowledge and experiences.

- Participate in training programs and certifications offered by machine manufacturers.

- Provide input to management on potential technology upgrades and process improvements.

9. How do you ensure the accuracy and efficiency of closing machine operations?

Accuracy and efficiency are essential for successful closing machine operations. I achieve this by:

- Following standardized operating procedures and quality control guidelines.

- Using precision measuring tools to ensure accurate machine setup and product dimensions.

- Performing regular machine calibration and maintenance to minimize errors and downtime.

- Monitoring machine performance and making adjustments as needed to optimize efficiency.

- Seeking feedback from supervisors and colleagues to identify areas for improvement.

10. How do you handle challenging work environments and tight deadlines?

Challenging work environments and tight deadlines are common in manufacturing. I thrive in these situations by:

- Maintaining a positive and proactive attitude, even under pressure.

- Prioritizing tasks and managing my time effectively to meet deadlines.

- Communicating clearly with supervisors and colleagues to coordinate efforts.

- Seeking support and assistance from experienced individuals when needed.

- Learning from past experiences and adapting my approach to overcome challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Closing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Closing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Closing Machine Operator is responsible for the operation and maintenance of closing machines in a manufacturing or packaging environment.

1. Machine Operation

Operate closing machines to seal containers, such as boxes, bags, or bottles, according to specified procedures.

- Adjust machine settings to ensure proper closure.

- Monitor machine operation and make adjustments as needed.

2. Machine Maintenance

Perform routine maintenance and cleaning of closing machines.

- Lubricate moving parts.

- Replace worn or damaged parts.

3. Quality Control

Inspect closed containers for defects and ensure they meet quality standards.

- Identify and correct any problems with the sealing process.

- Maintain records of machine performance and quality.

4. Safety

Follow safety procedures and wear appropriate personal protective equipment.

- Operate machines in a safe and responsible manner.

- Report any unsafe conditions or practices.

Interview Tips

Preparing for an interview for a Closing Machine Operator position requires careful consideration of both the technical and interpersonal aspects of the role.

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific responsibilities of the Closing Machine Operator position. This will help you understand the company’s culture, goals, and expectations for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Highlight Your Technical Skills

During the interview, emphasize your technical skills and experience in operating and maintaining closing machines. Provide specific examples of your ability to troubleshoot and resolve machine problems independently.

- Discuss your experience with different types of closing machines.

- Explain your knowledge of quality control procedures and standards.

3. Demonstrate Your Safety Awareness

Safety is paramount in any manufacturing environment. In the interview, demonstrate your understanding of safety protocols and your commitment to following them. Highlight your experience with lockout/tagout procedures and other safety measures.

- Discuss your experience with safety training and certification programs.

- Explain how you would respond to potential safety hazards in the workplace.

4. Prepare Behavioral Interview Answers

Behavioral interview questions are commonly used to assess your problem-solving, communication, and teamwork skills. Prepare examples of how you have handled challenging situations, resolved conflicts, and worked effectively in a team environment.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Tailor your answers to the specific requirements of the Closing Machine Operator role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Closing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Closing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.