Feeling lost in a sea of interview questions? Landed that dream interview for Cloth Doubling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cloth Doubling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

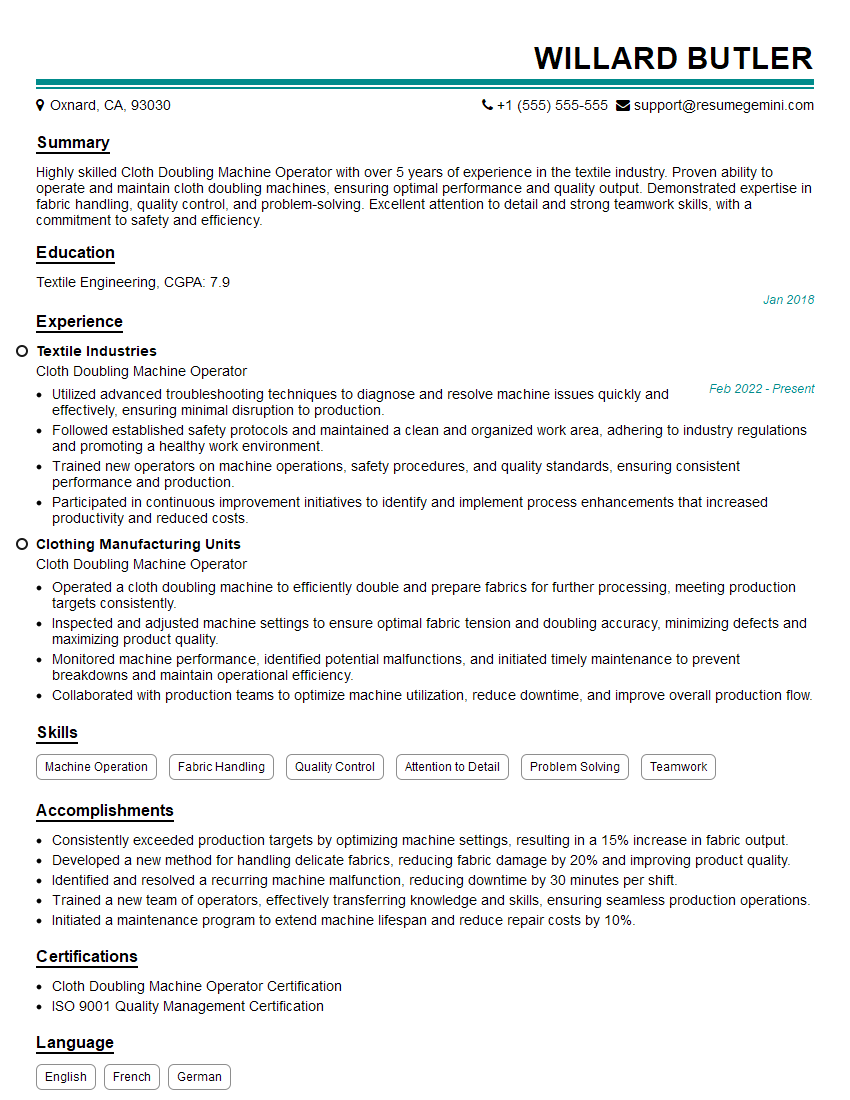

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Doubling Machine Operator

1. What are the different types of cloth doubling machines?

There are two main types of cloth doubling machines:

1. Single Head Cloth Doubling Machine

2. Double Head Cloth Doubling Machine

2. What are the key features of a cloth doubling machine?

Features of Single Head Cloth Doubling Machine

- High speed operation

- Automatic tension control

- Easy to operate

Features of Double Head Cloth Doubling Machine

- Can process two fabrics at once

- Equipped with latest PLC control system

- High efficiency and low noise

3. How do you operate a cloth doubling machine?

The steps involved in operating a cloth doubling machine are as follows:

1. Load the fabric onto the machine.

2. Set the machine to the desired settings.

3. Start the machine.

4. Monitor the machine’s operation.

5. Stop the machine when the fabric is finished being doubled.

4. What are the common problems that can occur with cloth doubling machines?

- Fabric tension problems

- Fabric wrinkling

- Machine breakdowns

5. How do you troubleshoot and repair common problems with cloth doubling machines?

- Check the fabric tension settings.

- Check the fabric for wrinkles.

- Check the machine for any loose or damaged parts.

6. What are the safety precautions that should be taken when operating a cloth doubling machine?

- Wear appropriate safety gear.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is not in good working order.

7. What are the different types of fabrics that can be doubled on a cloth doubling machine?

- Cotton

- Polyester

- Nylon

- Silk

8. What are the different applications for doubled fabrics?

- Apparel

- Home furnishings

- Industrial products

9. What are the advantages of using a cloth doubling machine?

- Increased fabric strength

- Improved fabric appearance

- Reduced fabric costs

10. What are the disadvantages of using a cloth doubling machine?

- Increased fabric weight

- Reduced fabric flexibility

- Potential for fabric damage

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Doubling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Doubling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cloth Doubling Machine Operators are responsible for overseeing the operation of cloth doubling machines in textile mills or garment factories. They work with a team to ensure that the machines are running efficiently and that the fabric is being produced to the correct specifications. Key Job Responsibilities include:

1. Operating Cloth Doubling Machines

Cloth Doubling Machine Operators are responsible for setting up, operating, and maintaining cloth doubling machines. These machines take two or more layers of fabric and sew them together, creating a single, thicker layer.

- Setting up the machine according to the fabric specifications

- Loading the fabric onto the machine

- Starting the machine and monitoring its operation

- Making adjustments to the machine as needed

- Unloading the finished fabric from the machine

2. Maintaining Cloth Doubling Machines

In addition to operating the machines, Cloth Doubling Machine Operators are also responsible for maintaining them. This includes cleaning and lubricating the machines, as well as making minor repairs.

- Cleaning the machine regularly

- Lubricating the machine according to the manufacturer’s instructions

- Inspecting the machine for any damage or wear and tear

- Making minor repairs to the machine

- Reporting any major problems to a supervisor

3. Ensuring Quality Control

Cloth Doubling Machine Operators are responsible for ensuring that the fabric produced by the machines meets the required quality standards. This includes checking the fabric for defects, such as holes, tears, or uneven stitching.

- Inspecting the fabric for defects

- Rejecting any fabric that does not meet the quality standards

- Reporting any quality problems to a supervisor

4. Working as Part of a Team

Cloth Doubling Machine Operators typically work as part of a team. They may work with other operators to load and unload the machines, or they may work with inspectors to check the quality of the fabric.

- Working with other operators to load and unload the machines

- Working with inspectors to check the quality of the fabric

- Communicating with other team members to ensure that the machines are running smoothly

Interview Tips

Here are some tips for acing an interview for a Cloth Doubling Machine Operator position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and what they’re looking for in an ideal candidate.

- Visit the company’s website

- Read the job description carefully

- Look for news articles or social media posts about the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Think about your strengths and weaknesses

- Prepare examples of your work experience that demonstrate your skills

- Be prepared to talk about your reasons for wanting to work for the company

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Consider wearing a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothing or revealing clothing

4. Be on time

Punctuality is important, so be sure to arrive for your interview on time. If you’re running late, call the interviewer to let them know.

- Give yourself plenty of time to get to the interview

- If you’re running late, call the interviewer to let them know

- Don’t arrive more than 15 minutes early for your interview

5. Be confident and enthusiastic

Confidence is key in an interview. Make sure to maintain eye contact, speak clearly, and project a positive attitude.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and enthusiastic about the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cloth Doubling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!