Are you gearing up for an interview for a Cloth Printer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cloth Printer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

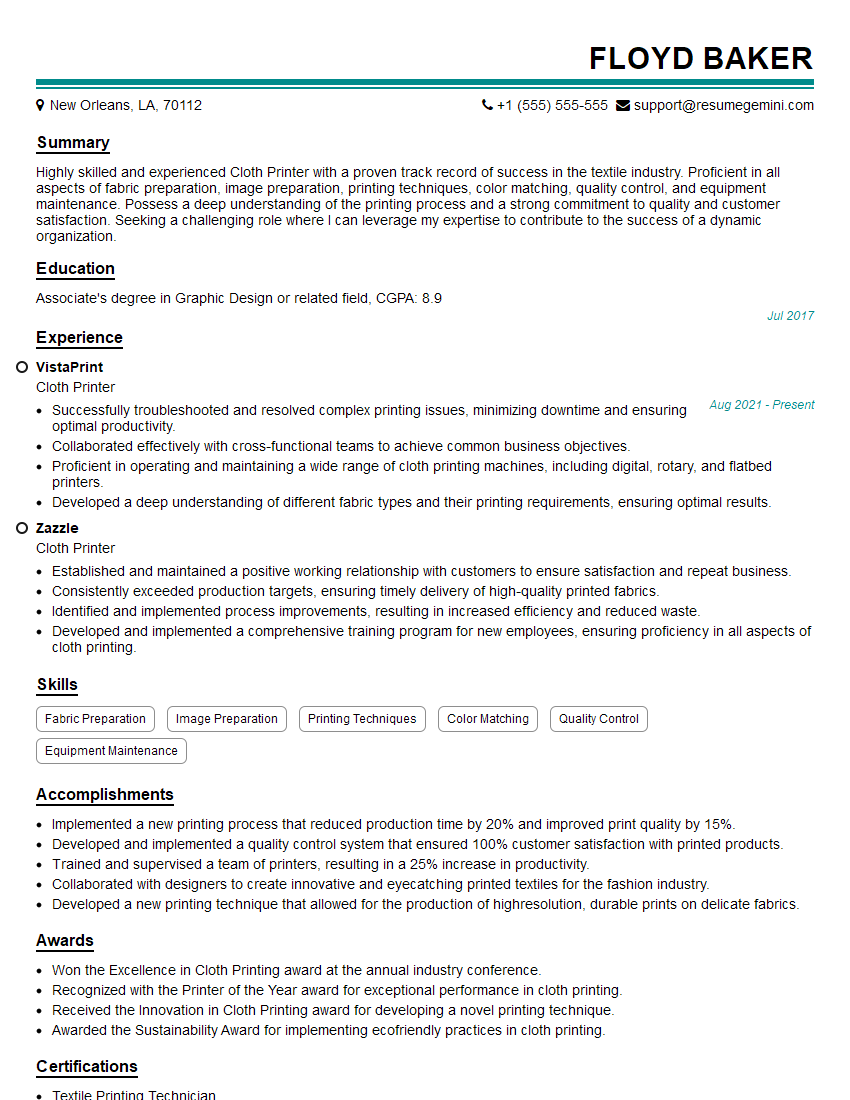

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Printer

1. What are the different types of cloth printing techniques? Please describe each one briefly.

- Screen printing: Involves using a mesh screen to transfer ink onto fabric. It’s a versatile technique that can produce high-quality prints with various colors and patterns.

- Digital printing: Uses inkjet technology to print directly onto fabric. It offers precise color control and allows for complex designs and photo-realistic images.

- Sublimation printing: Transfers dye onto fabric using heat and pressure. It produces vibrant colors that are resistant to fading and wear.

- Discharge printing: Removes the original dye from the fabric and replaces it with a new one. It creates soft, vintage-looking prints.

- Heat transfer printing: Uses a carrier sheet to transfer pre-printed designs onto fabric. It’s suitable for small or detailed prints.

2. What are the key factors to consider when choosing a cloth printing technique?

Fabric type:

- Different fabrics may require specific printing techniques to achieve optimal results.

- Consider the fabric’s fiber content, texture, and weave.

Design complexity:

- Complex designs with multiple colors or fine details may require specialized techniques.

- Determine the level of detail and precision needed for the design.

Budget and turnaround time:

- Different techniques vary in cost and production time.

- Consider the project’s budget and deadlines.

3. How do you ensure accurate color matching in cloth printing?

- Calibrate printing equipment regularly.

- Use color profiles and swatch books to ensure consistency.

- Communicate color specifications clearly with clients.

- Proof prints and make adjustments as needed.

- Use color management software to control color accuracy throughout the printing process.

4. What are the common printing defects and how do you troubleshoot them?

- Registration errors: Misalignment of colors or designs. Check the registration marks and adjust the printing press accordingly.

- Color bleeding: Excessive ink transfer from one color to another. Use proper ink viscosity and drying time, or consider using a barrier film.

- Ghosting: Faint duplicate images appearing on the fabric. Clean the printing screen or adjust the ink drying time.

- Pinholes: Small holes or imperfections in the print. Check the fabric for holes or tears, or adjust the screen pressure.

- Smudging: Blurred or smeared print. Use proper ink viscosity or adjust the drying time.

5. How do you handle customer complaints and ensure customer satisfaction?

- Listen attentively to the customer’s concerns.

- Identify the root cause of the issue.

- Propose solutions and discuss options with the customer.

- Follow up with the customer to ensure their satisfaction.

- Maintain a positive and professional demeanor throughout the complaint resolution process.

6. What are the latest trends in cloth printing technology?

- Digital printing advancements: Improved print quality, faster turnaround times, and wider design possibilities.

- Sustainable printing practices: Use of eco-friendly inks, fabrics, and printing processes.

- 3D printing for textiles: Creating unique and customizable fabric structures.

- Personalized printing: On-demand production of custom-designed fabrics for consumers.

7. How do you stay up-to-date with the latest industry techniques and practices?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Conduct research and experiment with new techniques.

- Seek mentorship or training from experienced professionals.

8. What are the safety precautions that need to be taken when working in a cloth printing environment?

- Wear appropriate protective gear (e.g., gloves, masks, safety glasses).

- Operate machinery safely and follow manufacturer’s instructions.

- Handle hazardous chemicals with care and dispose of them properly.

- Maintain a clean and well-ventilated work area.

- Be aware of potential fire hazards and have fire safety equipment readily available.

9. How do you manage your time and prioritize tasks effectively in a fast-paced production environment?

- Establish a clear workflow and prioritize tasks based on urgency and importance.

- Break down large projects into smaller, manageable tasks.

- Delegate tasks to team members when possible.

- Use time management tools (e.g., calendars, to-do lists).

- Communicate effectively with colleagues and supervisors to stay on track.

10. What is your approach to continuous improvement in your work?

- Identify areas for improvement through self-reflection and feedback from others.

- Research and explore new techniques and practices.

- Seek opportunities for training and development.

- Implement improvements and monitor their effectiveness.

- Regularly evaluate and adjust my approach based on results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cloth Printer is responsible for all printing operations, ensuring impeccable results and maintaining high-quality standards. Their core duties include:

1. Fabric Preparation

Preparing fabrics by inspecting, cleaning, and pretreating them to ensure optimal printing quality.

2. Printer Setup and Calibration

Setting up and calibrating printing machines, selecting appropriate inks and fabrics, and testing color accuracy.

3. Printing Operation

Operating printing machines to print designs onto fabrics, adhering to specifications and maintaining consistent print quality.

4. Quality Control

Inspecting printed fabrics for defects, color accuracy, and adherence to specifications, ensuring customer satisfaction.

5. Equipment Maintenance

Cleaning and maintaining printing equipment, performing minor repairs, and ensuring optimal performance.

6. Safety and Compliance

Adhering to safety regulations and maintaining a clean and organized work environment, ensuring the safety of themselves and others.

Interview Tips

Preparing for a Cloth Printer interview requires a combination of industry knowledge, preparation, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company’s background, values, and the specific role you’re applying for. This will help you tailor your answers and demonstrate your understanding of the company’s mission.

2. Highlight Your Technical Skills

Emphasize your proficiency in fabric printing techniques, including fabric preparation, printer setup, color matching, and quality control. Showcase your ability to operate different types of printing equipment and experience with various fabrics.

3. Demonstrate Quality Consciousness

Stress your commitment to delivering high-quality prints and meeting customer expectations. Provide specific examples of how you ensured accuracy, consistency, and defect prevention in previous roles.

4. Showcase Attention to Detail

Highlight your meticulous approach to fabric preparation, printer calibration, and quality inspection. Emphasize your ability to identify and correct potential errors before they impact production.

5. Prepare for Common Interview Questions

Anticipate questions about your experience with different printing techniques, color matching, fabric handling, and troubleshooting. Prepare concise and informative answers that demonstrate your technical expertise.

6. Soft Skills Matter

Beyond technical skills, interviewers also value teamwork, communication, and problem-solving abilities. Highlight instances where you effectively collaborated with others, communicated clearly, and resolved challenges in a timely manner.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cloth Printer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.