Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cloth Printing Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

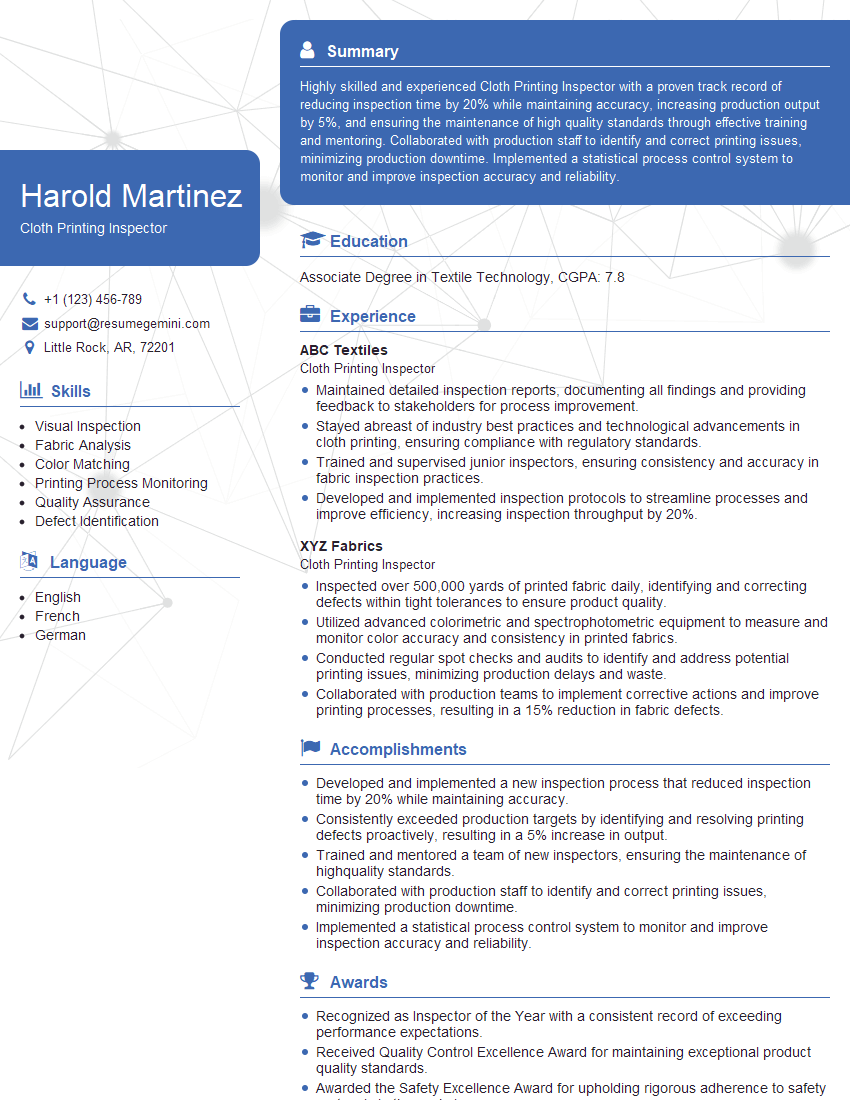

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Printing Inspector

1. What are the key factors you consider when inspecting printed fabrics?

When inspecting printed fabrics, I pay close attention to several key factors to ensure quality and accuracy:

- Color accuracy: I verify that the printed colors match the approved color standards.

- Print clarity: I check for sharp and well-defined print details, ensuring no smudging or blurring.

- Fabric alignment: I inspect the fabric alignment to ensure that the print is correctly positioned and centered.

- Fabric quality: I examine the fabric for any flaws, stains, or damages that could affect the print quality.

- Durability: I assess the print’s durability by conducting tests for colorfastness, wash resistance, and abrasion resistance.

2. Describe your process for identifying and resolving printing defects.

Identifying Defects

- Visually inspect the printed fabric for any visible defects, such as misprints, streaks, or color inconsistencies.

- Use specialized equipment like magnifying glasses or microscopes to examine the fabric closely for subtle defects.

- Review production logs and compare the printed fabric with the original design specifications to identify potential deviations.

Resolving Defects

- Communicate the defects to the production team and provide detailed documentation of the issue.

- Analyze the cause of the defect, whether it’s related to the printing process, fabric quality, or design specifications.

- Collaborate with the team to implement corrective actions to prevent future defects.

3. What is your experience with different printing techniques, such as screen printing, digital printing, and sublimation printing?

I have extensive experience with various printing techniques, including:

- Screen printing: I understand the setup, ink viscosity, and screen tensioning involved in screen printing.

- Digital printing: I am proficient in operating digital printers, managing color profiles, and ensuring print quality.

- Sublimation printing: I have experience with dye-sublimation processes, including heat and pressure settings, and fabric preparation.

4. How do you stay up-to-date with the latest quality control and inspection technologies?

I maintain my knowledge of the latest quality control and inspection technologies through several channels:

- Industry publications: I subscribe to industry magazines and journals to read about new advancements.

- Conferences and webinars: I attend industry conferences and webinars to learn about best practices and emerging technologies.

- Online resources: I regularly access online platforms and forums to connect with experts and stay informed.

- In-house training: I participate in company-organized training programs to enhance my skills and knowledge.

5. How do you handle situations where the production team disagrees with your inspection findings?

When faced with disagreements from the production team, I follow a structured approach:

- Maintain professionalism: I remain respectful and avoid confrontations.

- Provide clear evidence: I present detailed documentation, inspection reports, and samples to support my findings.

- Discuss objectively: I engage in open and objective discussions, explaining my reasoning and technical observations.

- Collaborate for solutions: I work with the production team to find mutually agreeable solutions that meet quality standards.

6. Describe your experience with quality management systems, such as ISO 9001 or Six Sigma.

I have a solid understanding of quality management systems, including ISO 9001 and Six Sigma:

- ISO 9001: I am familiar with the principles and requirements of ISO 9001, ensuring process standardization and quality control.

- Six Sigma: I have applied Six Sigma methodologies to improve processes, reduce defects, and enhance overall quality.

7. How do you manage time effectively when faced with multiple inspection tasks and deadlines?

I prioritize and manage my time effectively to meet deadlines and ensure quality:

- Prioritization: I assess the importance and urgency of inspection tasks to determine which ones require immediate attention.

- Scheduling: I create a detailed schedule that allocates time for each inspection task, allowing for buffer time.

- Delegation: When necessary, I delegate certain tasks to qualified colleagues to ensure timely completion.

- Communication: I communicate regularly with supervisors and colleagues to update them on my progress and any potential delays.

8. What are your strengths and weaknesses as a Cloth Printing Inspector?

Strengths:

- Technical expertise: I have a deep understanding of printing techniques, quality control standards, and industry best practices.

- Attention to detail: I possess a meticulous eye for detail and a keen ability to identify defects and inconsistencies.

- Problem-solving skills: I am skilled at analyzing problems, identifying root causes, and implementing effective solutions.

- Communication skills: I can effectively communicate inspection findings, collaborate with team members, and provide clear documentation.

Weaknesses:

- Limited experience with certain printing technologies: While I have experience with multiple printing techniques, I am still seeking opportunities to expand my knowledge in specific areas.

- Language barrier: As a non-native English speaker, I sometimes encounter challenges in communicating complex technical concepts.

9. How do you ensure the accuracy and reliability of your inspection results?

I follow rigorous protocols to ensure the accuracy and reliability of my inspection results:

- Standardized procedures: I adhere to established inspection procedures that minimize subjectivity and ensure consistent results.

- Calibrated equipment: I use calibrated measuring instruments and equipment to ensure accurate measurements.

- Regular audits: I participate in regular audits to verify the accuracy and effectiveness of my inspection methods.

- Documentation: I maintain detailed inspection reports and records that provide traceability and support my findings.

10. What is your approach to continuous improvement in the quality of printed fabrics?

I believe in continuous improvement and actively seek opportunities to enhance the quality of printed fabrics:

- Data analysis: I analyze inspection data to identify trends, patterns, and areas for improvement.

- Collaboration: I work closely with the production team, designers, and suppliers to identify and address potential quality issues.

- Research and innovation: I stay abreast of new technologies and advancements in the printing industry to explore opportunities for improvement.

- Training and development: I participate in training programs and workshops to enhance my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Printing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Printing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cloth Printing Inspectors play a critical role in ensuring the quality of printed fabrics, guaranteeing that they meet the desired specifications and customer expectations. Their primary responsibilities include:

1. Fabric Inspection

Inspecting printed fabrics for defects, such as color discrepancies, misprints, stains, and other imperfections.

- Utilizing visual inspection techniques and specialized equipment to detect even the smallest flaws.

- Assessing the quality of printing based on established standards and customer requirements.

2. Quality Control

Maintaining high standards of quality by identifying and addressing non-conformities in the printing process.

- Implementing corrective measures to prevent the recurrence of defects.

- Working closely with production teams to ensure the smooth operation of printing machines.

3. Reporting and Documentation

Recording inspection findings and reporting any discrepancies to supervisors or managers.

- Maintaining accurate records of inspections and quality checks.

- Providing feedback to improve printing processes and reduce defects.

4. Customer Support

Collaborating with customers to understand their specific requirements and expectations.

- Resolving customer concerns related to fabric quality and ensuring their satisfaction.

- Providing technical assistance and guidance to customers on fabric care and maintenance.

Interview Tips

To ace the interview for the Cloth Printing Inspector position, candidates should prepare thoroughly and showcase their skills and experience. Here are some tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific role you are applying for. This will demonstrate your interest and enthusiasm.

- Visit the company’s website to learn about their values, products, and services.

- Read industry publications and news articles to stay informed about the latest trends and technologies in cloth printing.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience in fabric inspection, quality control, and customer support. Provide specific examples of your work and how you have contributed to improving fabric quality.

- Showcase your expertise in visual inspection techniques and your ability to detect even the smallest defects.

- Explain your experience in implementing corrective measures and working with production teams to resolve quality issues.

3. Prepare Questions for the Interviewer

Asking well-thought-out questions shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company.

- Ask about the company’s quality control standards and how they are maintained.

- Inquire about the opportunities for professional development and growth within the organization.

4. Practice Your Answers

Take the time to practice answering common interview questions related to fabric inspection and quality control. This will help you feel more confident and articulate during the interview.

- Practice describing your experience in identifying and resolving fabric defects.

- Prepare examples of how you have worked effectively with customers to address their concerns.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cloth Printing Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.