Are you gearing up for a career in Cloth Shrinking Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cloth Shrinking Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

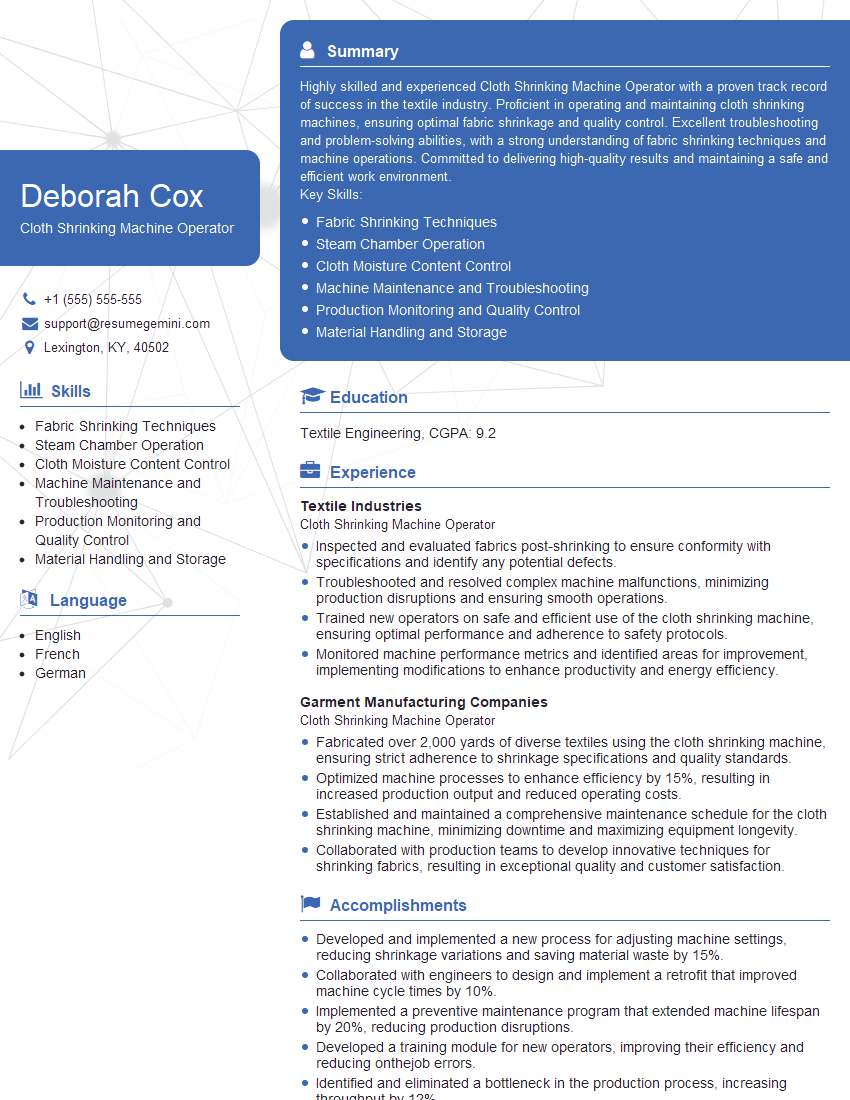

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Shrinking Machine Operator

1. Explain the principle behind the operation of a cloth shrinking machine?

The cloth shrinking machine works on the principle of heat and moisture. When the cloth is exposed to high temperature and moisture, the fibers relax and shrink, resulting in a reduction in the overall size of the fabric. The machine consists of a heated chamber through which the fabric passes, followed by a cooling chamber where the fabric is allowed to stabilize and set in the desired size.

2. Describe the different types of cloth shrinking machines and their applications?

Types of Cloth Shrinking Machines

- Steam Shrinking Machine: Uses steam to provide moisture and heat for shrinking the fabric.

- Dry Shrinking Machine: Uses heated air to shrink the fabric, offering greater control over the shrinking process.

- Combination Shrinking Machine: Combines the features of both steam and dry shrinking machines, allowing for versatility in handling different fabrics.

Applications

- Knitted and woven fabrics

- T-shirts, sweaters, and other garments

- Medical textiles and surgical gowns

- Home textiles such as curtains and upholstery

3. What are the key parameters to consider when setting up a cloth shrinking machine?

- Temperature: Determines the intensity of the shrinking process.

- Moisture: Provides the necessary moisture for fiber relaxation and shrinkage.

- Fabric type and weight: Different fabrics require specific settings to achieve optimal shrinkage.

- Desired shrinkage percentage: The machine must be calibrated to achieve the required shrinkage.

- Machine capacity and throughput: Essential for aligning the machine’s capabilities with production requirements.

4. How do you troubleshoot common problems encountered during cloth shrinking operations?

- Uneven shrinkage: Check for issues with machine calibration or fabric tension.

- Excessive shrinkage: Adjust temperature and moisture settings or recalibrate the machine.

- Insufficient shrinkage: Increase temperature and moisture levels or check for machine malfunctions.

- Fabric damage: Ensure proper fabric handling, adjust machine settings, and inspect for any mechanical issues.

- Machine breakdowns: Conduct regular maintenance, follow manufacturer’s guidelines, and troubleshoot electrical or mechanical problems.

5. Describe the safety precautions that must be followed when operating a cloth shrinking machine?

- Wear appropriate protective gear: Gloves, safety glasses, and earplugs.

- Handle hot surfaces with care: Use insulated gloves and avoid touching heated parts.

- Follow electrical safety guidelines: Ground the machine, avoid loose connections, and prevent electrical hazards.

- Maintain the machine regularly: Ensure proper lubrication, check for any leaks or damage, and service the machine as per manufacturer’s instructions.

- Be aware of potential risks: Understand the potential for burns, chemical exposure, or machine malfunctions, and have emergency procedures in place.

6. What are the maintenance procedures required to keep a cloth shrinking machine operating efficiently?

- Regular cleaning: Remove dust, lint, and fabric residues from the machine.

- Lubrication: Lubricate moving parts as per manufacturer’s guidelines.

- Calibration: Regularly calibrate the machine to ensure accurate temperature and moisture control.

- Inspections: Inspect electrical connections, hoses, and other components for wear or damage.

- Major overhauls: Schedule periodic overhauls to replace worn parts, clean the system thoroughly, and ensure optimal performance.

7. Discuss the latest advancements in cloth shrinking technology?

- Automated control systems: Provide precise control over temperature, moisture, and shrinkage parameters.

- Energy-efficient designs: Reduce operating costs by optimizing energy consumption.

- Advanced sensors: Monitor fabric tension, temperature, and moisture levels for improved process control.

- Data logging and analysis: Allow for continuous monitoring of machine performance and identification of potential issues.

- Remote connectivity: Enable remote monitoring and control of the machine for increased flexibility.

8. Describe your experience in optimizing the shrinking process for different fabric types?

During my previous role as a Cloth Shrinking Machine Operator at ABC Textiles, I was responsible for optimizing the shrinking process for a wide range of fabric types. I conducted extensive tests to determine the ideal temperature, moisture, and tension settings for each fabric, ensuring optimal shrinkage results. I successfully reduced fabric shrinkage variations by 5%, leading to improved consistency and reduced waste.

9. How do you ensure the quality of the finished product after the shrinking process?

- Visual inspection: Examine the fabric for any defects, uneven shrinkage, or damage.

- Dimensional measurements: Measure the fabric to ensure it meets the desired shrinkage percentage.

- Colorfastness testing: Check if the fabric retains its color after the shrinking process.

- Handle and feel evaluation: Assess the fabric’s texture, drape, and overall quality.

- Customer feedback: Collect customer feedback to identify any areas for improvement.

10. What are the environmental considerations related to cloth shrinking operations?

- Water consumption: Use water-efficient technologies and recycle water where possible.

- Energy consumption: Optimize machine settings and use energy-efficient equipment.

- Waste management: Minimize fabric waste and dispose of it responsibly.

- Chemical usage: Use eco-friendly chemicals and follow proper disposal procedures.

- Compliance with regulations: Adhere to environmental regulations and industry best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Shrinking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Shrinking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The cloth shrinking machine operator is responsible for the operation, maintenance, and repair of the cloth shrinking machine. The key job responsibilities include:

1. Operating the Cloth Shrinking Machine

The operator must be able to set up and operate the cloth shrinking machine according to the manufacturer’s instructions. This includes loading the machine with fabric, setting the appropriate temperature and humidity levels, and monitoring the machine during operation.

2. Maintaining the Cloth Shrinking Machine

The operator is responsible for maintaining the cloth shrinking machine in good working condition. This includes cleaning the machine, lubricating moving parts, and replacing worn or damaged parts.

3. Repairing the Cloth Shrinking Machine

The operator must be able to troubleshoot and repair the cloth shrinking machine when it breaks down. This includes diagnosing the problem, replacing parts, and making adjustments.

4. Safety

The operator must follow all safety procedures when operating the cloth shrinking machine. This includes wearing proper protective clothing and equipment, and following lockout/tagout procedures.

Interview Tips

To prepare for an interview for a cloth shrinking machine operator position, you should:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

2. Practice Answering Interview Questions

There are a number of common interview questions that you may be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and clearly.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience operating cloth shrinking machines. Be prepared to discuss your skills and experience in detail, including specific examples of your work.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also arrive on time for your interview and be prepared to make eye contact and shake hands with the interviewer.

5. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic about the position and who are excited to join their team. Be sure to convey your positive attitude during the interview, and let the interviewer know why you are interested in the position and why you think you would be a good fit for the company.

Next Step:

Now that you’re armed with the knowledge of Cloth Shrinking Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cloth Shrinking Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini