Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cloth Shrinking Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cloth Shrinking Tester so you can tailor your answers to impress potential employers.

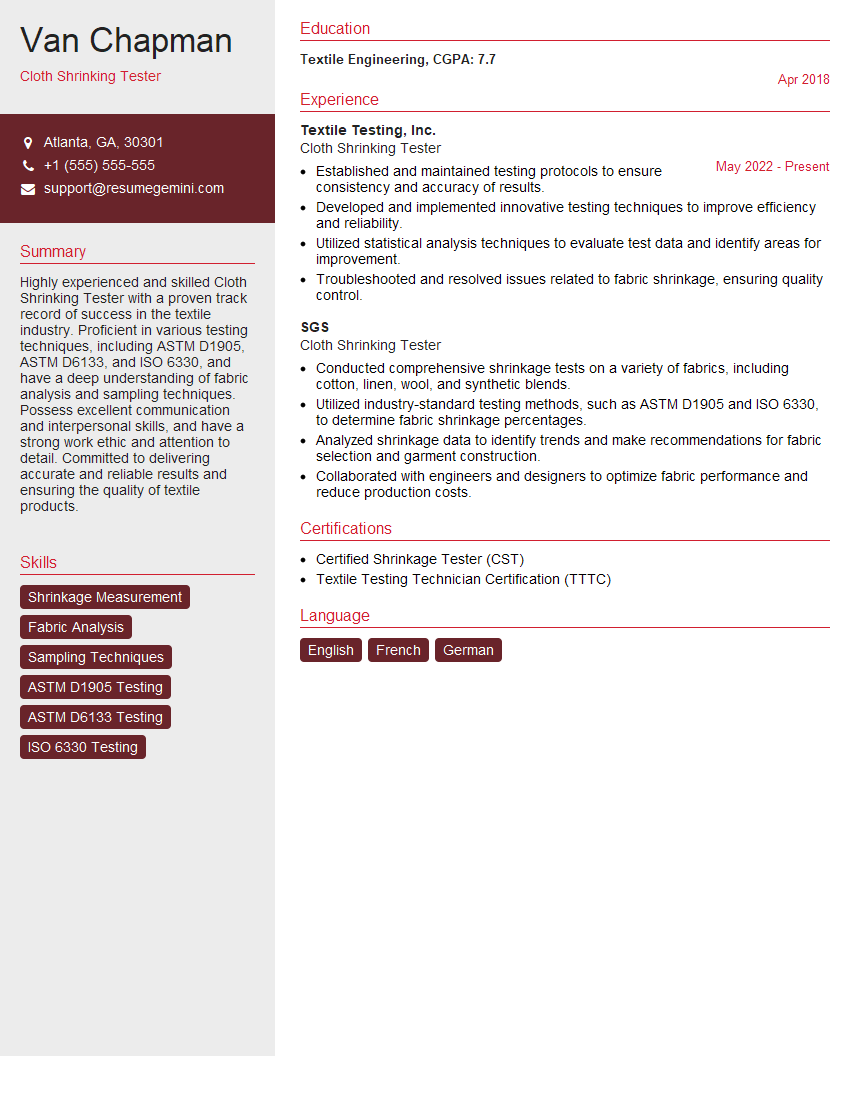

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Shrinking Tester

1. What are the different methods used to measure the shrinkage of fabrics?

There are several methods used to measure the shrinkage of fabrics, including:

- ASTM D2090: This method uses a specimen of fabric that is washed and dried under controlled conditions, and the change in dimensions is measured.

- ASTM D2259: This method uses a specimen of fabric that is immersed in hot water and then dried, and the change in dimensions is measured.

- AATCC 190: This method uses a specimen of fabric that is washed and dried under controlled conditions, and the change in weight is measured.

2. How does the type of fabric affect its shrinkage?

Fiber content

- Natural fibers (e.g., cotton, wool) tend to shrink more than synthetic fibers (e.g., polyester, nylon).

Weave

- Fabrics with a tight weave (e.g., canvas) tend to shrink less than fabrics with a loose weave (e.g., gauze).

Finish

- Fabrics that have been treated with a shrink-resistant finish will shrink less than untreated fabrics.

3. What are the factors that can affect the accuracy of shrinkage measurements?

- Sample size: The larger the sample size, the more accurate the measurement will be.

- Washing and drying conditions: The temperature, duration, and agitation of the wash and dry cycles can affect the shrinkage of the fabric.

- Measurement technique: The method used to measure the shrinkage of the fabric can affect the accuracy of the measurement.

4. What are the typical shrinkage rates for different types of fabrics?

- Cotton: 2-5%

- Wool: 5-10%

- Polyester: 0-2%

- Nylon: 0-1%

5. How can shrinkage be prevented or minimized?

- Choose fabrics that have a low shrinkage rate: Natural fibers (e.g., cotton, wool) tend to shrink more than synthetic fibers (e.g., polyester, nylon).

- Wash and dry fabrics according to the manufacturer’s instructions: Washing and drying fabrics at high temperatures or with excessive agitation can cause them to shrink.

- Use a fabric softener: Fabric softeners can help to reduce shrinkage by coating the fibers of the fabric and making them less likely to cling to each other.

6. What are the consequences of excessive shrinkage?

- Garments may become too small to wear

- Fabrics may become distorted or puckered

- Fabrics may lose their strength and durability

7. What are the latest advancements in shrinkage testing technology?

- Digital image analysis: This technology uses a digital camera to capture images of the fabric before and after it is washed and dried, and then uses software to measure the change in dimensions.

- Laser scanning: This technology uses a laser scanner to measure the dimensions of the fabric before and after it is washed and dried, and then uses software to calculate the change in dimensions.

8. What are the challenges associated with shrinkage testing?

- The accuracy of shrinkage measurements can be affected by a number of factors, including the sample size, the washing and drying conditions, and the measurement technique.

- Shrinkage testing can be time-consuming and expensive, especially for large samples.

9. What are the future trends in shrinkage testing?

- Digital image analysis and laser scanning are becoming increasingly popular, as they offer more accurate and efficient methods of shrinkage measurement.

- New technologies are being developed to reduce the cost and time required for shrinkage testing, such as the use of artificial intelligence (AI) to analyze data.

10. What are the most important qualities for a successful cloth shrinking tester?

- Attention to detail: Cloth shrinking testers must be able to carefully follow instructions and record data accurately.

- Technical skills: Cloth shrinking testers must be familiar with the equipment and techniques used in shrinkage testing.

- Problem-solving skills: Cloth shrinking testers must be able to troubleshoot problems and find solutions.

- Communication skills: Cloth shrinking testers must be able to communicate their findings clearly and concisely to both technical and non-technical audiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Shrinking Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Shrinking Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cloth Shrinking Testers are responsible for ensuring the quality of fabrics by conducting tests to determine their shrinkage properties. They play a crucial role in maintaining the standards and specifications of textiles, ensuring that they meet industry requirements.

1. Test Fabric Shrinkage

Conduct various tests, including ASTM D1905 and ISO 6330, to determine the percentage of shrinkage in fabrics when subjected to specific conditions such as washing, drying, or exposure to heat.

- Measure and record shrinkage values accurately to provide reliable data for analysis.

- Follow established testing procedures meticulously to ensure consistency and accuracy.

2. Evaluate Test Results

Analyze test results to identify deviations from specifications or industry standards.

- Identify potential causes of excessive shrinkage and suggest corrective actions.

- Recommend adjustments to fabric composition, construction, or finishing processes to improve shrink resistance.

3. Maintain Testing Equipment

Calibrate and maintain testing equipment regularly to ensure accuracy and reliability.

- Troubleshoot and repair equipment malfunctions promptly.

- Keep detailed records of equipment maintenance and calibration activities.

4. Generate and Maintain Records

Document all testing procedures, results, and observations in detailed reports.

- Maintain accurate records of fabric samples tested, including lot numbers and specifications.

- Communicate test results effectively to stakeholders, including fabric manufacturers, designers, and quality control personnel.

Interview Preparation Tips

To ace your interview for a Cloth Shrinking Tester position, thorough preparation is essential. Here are some tips to help you stand out:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends.

- Research competitors to demonstrate your understanding of the market landscape.

- Identify key challenges and opportunities in the textile industry.

2. Highlight Your Testing Expertise

Emphasize your proficiency in fabric testing methods, including ASTM and ISO standards.

- Provide specific examples of tests you have conducted and the results you obtained.

- Discuss your understanding of the factors that influence fabric shrinkage.

3. Demonstrate Analytical and Problem-Solving Skills

Explain how you analyze test results and identify potential problems.

- Describe a situation where you identified and resolved an issue related to fabric shrinkage.

- Explain your approach to troubleshooting and recommending corrective actions.

4. Showcase Your Communication and Documentation Skills

Highlight your ability to communicate test results clearly and concisely.

- Provide examples of technical reports you have written that effectively convey test findings.

- Explain how you maintain accurate and organized testing records.

5. Be Enthusiastic and Professional

Express your passion for textiles and your commitment to quality control.

- Prepare thoughtful questions to ask the interviewer, demonstrating your interest and attention to detail.

- Maintain a positive and professional demeanor throughout the interview, leaving a lasting impression.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cloth Shrinking Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cloth Shrinking Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.