Feeling lost in a sea of interview questions? Landed that dream interview for Cloth Spreader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cloth Spreader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

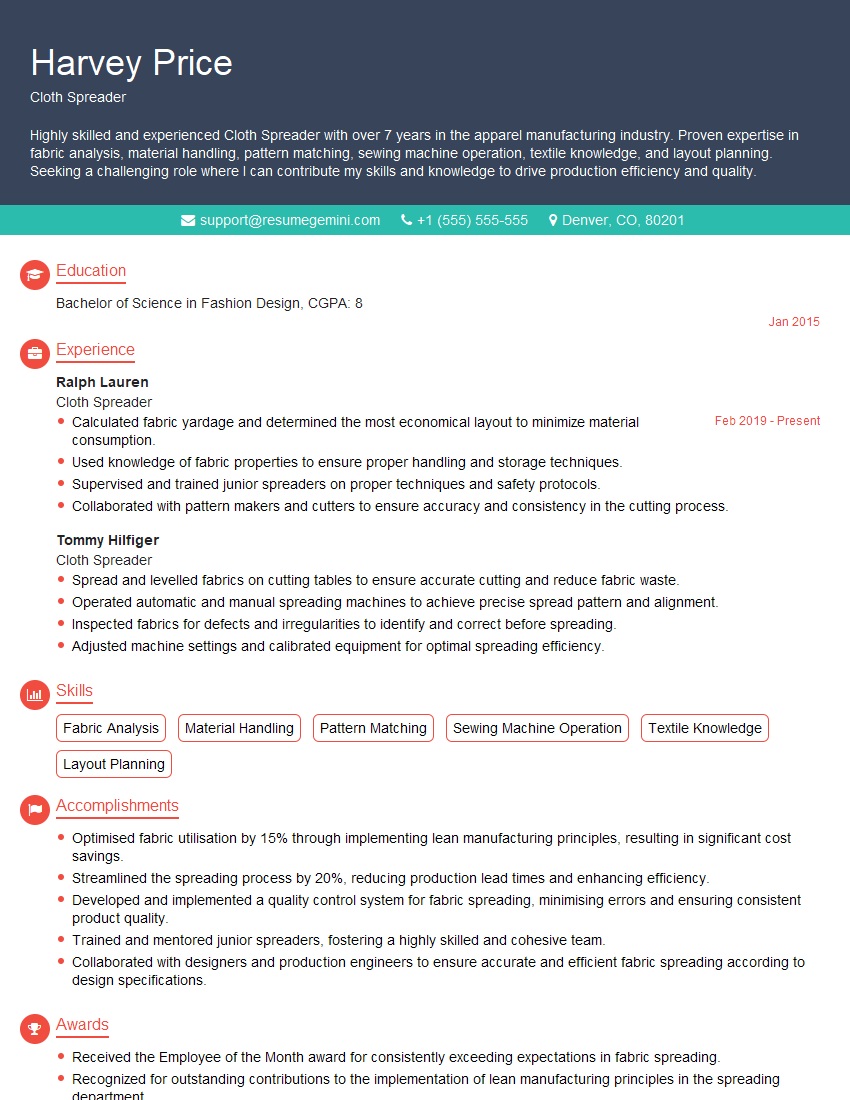

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Spreader

1. What are the key responsibilities of a Cloth Spreader?

As a Cloth Spreader, my responsibilities primarily involve preparing and laying out fabric layers for cutting in garment manufacturing. I ensure that the fabric is aligned correctly, the layers are properly stacked, and the spreading process meets the required specifications.

2. Explain the different types of spreading machines and their uses.

Manual Spreading Machines

- Used for small-scale production or custom orders

- Require manual labor to spread the fabric

Semi-Automatic Spreading Machines

- Provide assisted spreading with automated functions

- Increase efficiency and reduce physical labor

Fully-Automatic Spreading Machines

- Fully automated process with minimal manual intervention

- Offer high speed and precision

3. Describe the factors to consider when selecting the appropriate spreading method.

The selection of the spreading method depends on factors such as:

- Production volume

- Fabric type and weight

- Available space and budget

- Accuracy and precision requirements

4. How do you ensure the accuracy and precision of the spreading process?

Accuracy and precision are crucial in spreading. I follow these steps to ensure it:

- Calibrating the spreading machine regularly

- Verifying the fabric tension and alignment

- Inspecting the spread layers for defects or misalignments

- Using measuring tools and templates for precision

5. What is the importance of proper fabric handling during spreading?

Proper fabric handling is essential to maintain the fabric’s quality and prevent damage. I take care to:

- Handle the fabric with clean hands and gloves

- Avoid dragging or pulling the fabric

- Roll or fold the fabric properly to prevent creases or wrinkles

- Store the fabric in a controlled environment to prevent moisture or temperature damage

6. How do you troubleshoot common problems encountered during spreading?

Common problems include:

- Fabric misalignment: Adjust tension settings or verify machine calibration

- Fabric wrinkles: Use a steamer or iron to remove wrinkles

- Fabric tears: Inspect the fabric for defects or sharp objects

- Machine malfunctions: Contact the manufacturer for technical support

7. Explain the role of a spreader in ensuring fabric utilization.

Optimizing fabric utilization is crucial to minimize waste. As a spreader, I:

- Plan the layout to minimize fabric scraps

- Use nesting techniques to fit patterns efficiently

- Monitor fabric consumption and adjust spreading plans as needed

8. How do you stay updated with the latest spreading techniques and industry best practices?

I stay informed by:

- Attending industry events and workshops

- Reading trade publications and technical manuals

- Seeking training from equipment manufacturers

- Collaborating with experienced spreaders and supervisors

9. What are the safety precautions you observe while operating a spreading machine?

- Wear appropriate safety gear (gloves, safety glasses)

- Keep the work area clean and free of tripping hazards

- Ensure proper machine guarding and maintenance

- Follow established operating procedures and lockout/tagout protocols

- Report any safety concerns or malfunctions immediately

10. How do you prioritize tasks and manage your time effectively in a fast-paced production environment?

I prioritize tasks based on:

- Production deadlines

- Fabric availability

- Machine availability

- Skill level required

I use time management techniques such as:

- Creating a daily task list

- Breaking down large tasks into smaller steps

- Delegating tasks when appropriate

- Minimizing distractions and interruptions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Spreader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Spreader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cloth Spreaders are responsible for preparing fabric for cutting and sewing in the garment manufacturing industry. They play a crucial role in ensuring the accuracy and efficiency of the production process. Key job responsibilities include:

1. Fabric Preparation

Spreaders receive fabric rolls and inspect them for defects. They then prepare the fabric by unwinding it, aligning it, and spreading it out evenly on a cutting table.

2. Measuring and Marking

Spreaders measure and mark the fabric according to the garment patterns. They use various tools, such as rulers, measuring tapes, and chalk, to ensure precision and accuracy.

3. Layering and Cutting

Spreaders layer multiple layers of fabric on top of each other and secure them using pins or clamps. They then use a cutting machine or scissors to cut the fabric into the desired shapes and sizes.

4. Quality Control

Spreaders inspect the cut fabric for defects and ensure it meets the required specifications. They also check for any errors in measuring, marking, or cutting.

5. Machine Maintenance

Spreaders maintain and clean the fabric spreading and cutting machines. They perform regular inspections and lubricate moving parts as needed.

Interview Tips

Preparing thoroughly for the interview is essential to increase your chances of success. Here are some tips to help you ace the interview for a Cloth Spreader position:

1. Research the Company and Industry

Familiarize yourself with the company’s website, social media pages, and industry news. This knowledge will demonstrate your interest and understanding of the company’s operations and the garment manufacturing industry.

2. Practice Your Skills

Practice using the tools and techniques required for fabric spreading, such as measuring, marking, and cutting. This hands-on preparation will boost your confidence and enable you to clearly articulate your skills during the interview.

3. Highlight Your Experience

Emphasize your previous experience in fabric spreading or related fields. Showcase your knowledge of different fabric types, cutting techniques, and quality control procedures. Quantify your accomplishments whenever possible, using specific examples to demonstrate your impact.

4. Ask Thoughtful Questions

Asking insightful questions during the interview shows your engagement and interest in the position. Prepare questions that demonstrate your understanding of the role and the company’s operations. This also allows you to clarify any areas of uncertainty.

5. Dress Appropriately

First impressions matter, so dress professionally and comfortably for the interview. Consider wearing clothing suitable for a manufacturing environment, such as closed-toe shoes and practical attire that allows for movement and flexibility.

6. Be Punctual and Enthusiastic

Arrive on time for the interview and greet the interviewer with a positive and enthusiastic attitude. Punctuality and enthusiasm convey respect for the interviewer’s time and your interest in the opportunity.

7. Follow Up Professionally

After the interview, send a thank-you note to the interviewer within 24 hours. Express your appreciation for their time and reiterate your interest in the position. This follow-up demonstrates your professionalism and leaves a lasting positive impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cloth Spreader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!