Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cloth Stock Sorter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

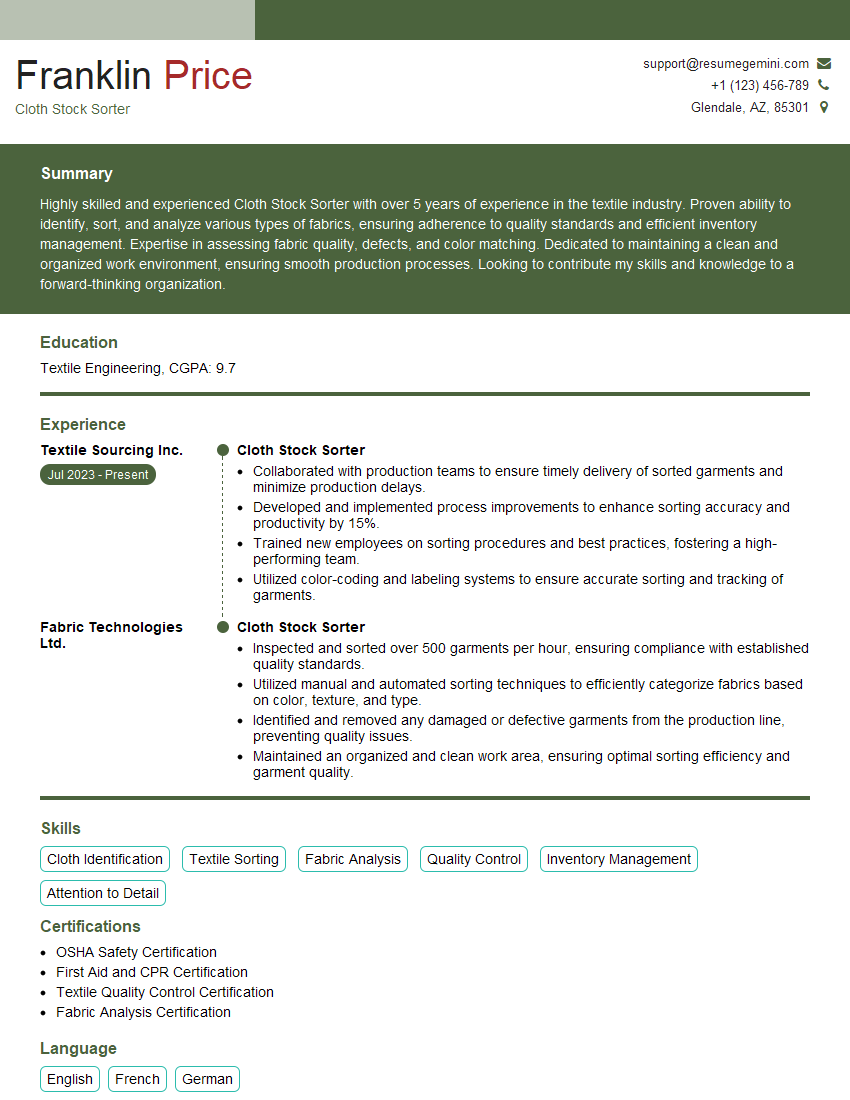

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Stock Sorter

1. How do you ensure accuracy when sorting cloth according to various criteria?

To ensure accuracy when sorting cloth according to various criteria, I implement the following techniques:

- Meticulously review each piece of cloth to identify and categorize its specific characteristics (e.g., color, pattern, fabric type, size, etc.)

- Utilize specialized equipment and tools, such as color sorters or barcode scanners, to automate the sorting process and minimize human error

- Establish and adhere to clear and consistent sorting guidelines to ensure consistency and reduce the risk of mistakes

- Regularly calibrate sorting equipment to ensure its accuracy and prevent errors caused by faulty devices

- Conduct regular self-checks and peer reviews to identify and address any potential inconsistencies or errors in the sorting process

2. Describe your process for identifying and resolving discrepancies in cloth during the sorting process.

To effectively identify and resolve discrepancies during the cloth sorting process, I follow these steps:

Identifying Discrepancies:

- Continuously inspect the cloth as it passes through the sorting line

- Pay attention to any deviations from the established sorting criteria or expected patterns

- Utilize technology, such as optical sorters or scanners, to detect and flag potential discrepancies

- Cross-check with other team members, supervisors, or quality control personnel to confirm any irregularities

Resolving Discrepancies:

- Isolating the affected cloth and documenting the details of the discrepancy (e.g., type of error, cause, etc.)

- Consulting with supervisors or subject matter experts to determine the appropriate course of action

- Re-evaluating the affected cloth to ensure that the discrepancy has been resolved and the correct sorting criteria are followed

3. What methods do you use to enhance your sorting speed and efficiency?

To improve my cloth sorting speed and efficiency, I employ the following techniques:

- Optimizing the sorting process by identifying and eliminating bottlenecks or inefficiencies

- Utilizing ergonomic sorting workstations and equipment to reduce physical strain and fatigue, allowing for sustained performance

- Implementing lean principles, such as 5S and Kaizen, to improve organization and workflow

- Regularly practicing and refining sorting techniques to enhance dexterity and accuracy

- Collaborating with other team members to ensure a smooth and coordinated sorting operation

4. Can you describe the role of quality control in the cloth sorting process, and how you contribute to it?

Quality control plays a crucial role in the cloth sorting process, and I actively contribute to it through the following measures:

- Adhering to established quality standards and specifications to ensure that the sorted cloth meets the required criteria

- Conducting regular self-inspections and peer reviews to identify and address any potential quality issues

- Utilizing quality control tools and techniques, such as statistical process control (SPC) and root cause analysis, to identify and eliminate sources of errors

- Providing feedback and suggestions to supervisors and quality control personnel to improve the overall sorting process and maintain high quality standards

5. What safety precautions do you observe when operating cloth sorting machinery?

To ensure a safe working environment, I strictly follow these safety precautions when operating cloth sorting machinery:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hairnet, to minimize the risk of injuries

- Ensuring that the machinery is properly installed, maintained, and calibrated to prevent malfunctions or accidents

- Following established safety procedures and protocols for operating the machinery safely

- Being aware of potential hazards and taking appropriate measures to avoid them, such as keeping the work area clear and free of obstructions

- Reporting any safety concerns or equipment issues to supervisors immediately for prompt resolution

6. How do you deal with high-volume sorting tasks while maintaining accuracy?

When faced with high-volume sorting tasks, I employ the following strategies to maintain accuracy:

- Breaking down the task into smaller, manageable batches to avoid overwhelming myself and reduce the risk of errors

- Prioritizing the tasks based on importance and urgency, focusing on completing the most critical items first

- Utilizing efficient sorting techniques and automation tools to minimize the time required per item

- Maintaining a high level of focus and concentration throughout the sorting process, minimizing distractions

- Taking regular breaks to prevent fatigue and maintain my accuracy levels

7. How do you handle situations where there are multiple sorting criteria to consider?

When sorting cloth according to multiple criteria, I follow these steps to ensure accuracy and efficiency:

- Carefully reviewing the sorting specifications to understand the importance and priority of each criterion

- Developing a logical sorting sequence based on the criteria, starting with the most significant or specific characteristics

- Using specialized equipment or tools to assist with the sorting, such as multi-channel sorters or barcode scanners

- Double-checking the sorted items to ensure that they meet all the specified criteria

- Seeking guidance from supervisors or quality control personnel if any uncertainties or complexities arise

8. What do you do when you encounter damaged or defective cloth during the sorting process?

Upon identifying damaged or defective cloth during the sorting process, I take the following actions:

- Segregating the affected cloth from the acceptable items to prevent contamination or mixing

- Documenting the details of the damage or defect, including its type, location, and severity

- Informing supervisors or quality control personnel about the issue and seeking their guidance on the appropriate course of action

- Following established procedures for handling damaged or defective cloth, such as repairing, discarding, or returning it to the supplier

9. Can you describe a specific instance where you identified and resolved a sorting issue?

In a previous role, I encountered an issue where a particular type of cloth was consistently being misidentified during sorting. I conducted a thorough analysis of the sorting process, including the equipment and criteria used. After careful observation, I realized that the optical sorter was not properly calibrated to differentiate between two similar shades of the cloth. I recalibrated the sorter and implemented additional quality checks to ensure accuracy. As a result, the sorting error was eliminated, and the efficiency of the overall process improved.

10. How do you stay up-to-date on the latest sorting techniques and industry best practices?

To stay current with the latest sorting techniques and industry best practices, I engage in the following activities:

- Attending industry conferences, workshops, and training programs to learn about new technologies and methodologies

- Reading trade publications, technical manuals, and research papers to keep abreast of advancements in the field

- Seeking mentorship from experienced professionals and subject matter experts to gain insights and practical knowledge

- Actively participating in industry forums, online communities, and knowledge-sharing platforms to connect with peers and exchange ideas

- Staying informed about industry regulations, standards, and best practices to ensure compliance and maintain high-quality standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Stock Sorter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Stock Sorter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cloth Stock Sorter is responsible for many key tasks within a warehouse or retail setting, including:

1. Sorting and categorizing cloth items

This involves examining cloth items, such as clothing and fabrics, to determine their type, size, and condition. They may also be responsible for grading the items based on quality.

- Identify different types of fabrics, such as cotton, silk, and wool.

- Sort items by size, color, and style.

2. Maintaining inventory records

Cloth Stock Sorters are often responsible for maintaining accurate inventory records. This may involve using a computer system to track the number of items in stock, as well as their location within the warehouse or store.

- Maintain accurate records of inventory levels.

- Update inventory records as items are received and shipped.

3. Preparing cloth items for storage or shipment

This may involve folding, hanging, or packaging items. Cloth Stock Sorters may also be responsible for labeling items with barcodes or other tracking information.

- Fold, hang, or package items according to company standards.

- Label items with barcodes or other tracking information.

4. Assisting customers with finding cloth items

In a retail setting, Cloth Stock Sorters may be responsible for assisting customers with finding the cloth items they are looking for. This may involve searching for items in the stockroom or helping customers to locate the correct size or style.

- Assist customers in locating cloth items.

- Answer customer questions about cloth items and their availability.

Interview Tips

In order to ace an interview for a Cloth Stock Sorter position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before going to the interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read online reviews of the company.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is a good idea to practice your answers to these questions in advance so that you can feel confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress professionally

It is important to dress professionally for an interview. This shows the interviewer that you are serious about the job and that you respect the company.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes that you can walk in easily.

4. Be on time

It is important to be on time for your interview. This shows the interviewer that you are punctual and that you respect their time.

- Give yourself plenty of time to get to the interview.

- If you are running late, call the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cloth Stock Sorter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!