Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cloth Winder Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

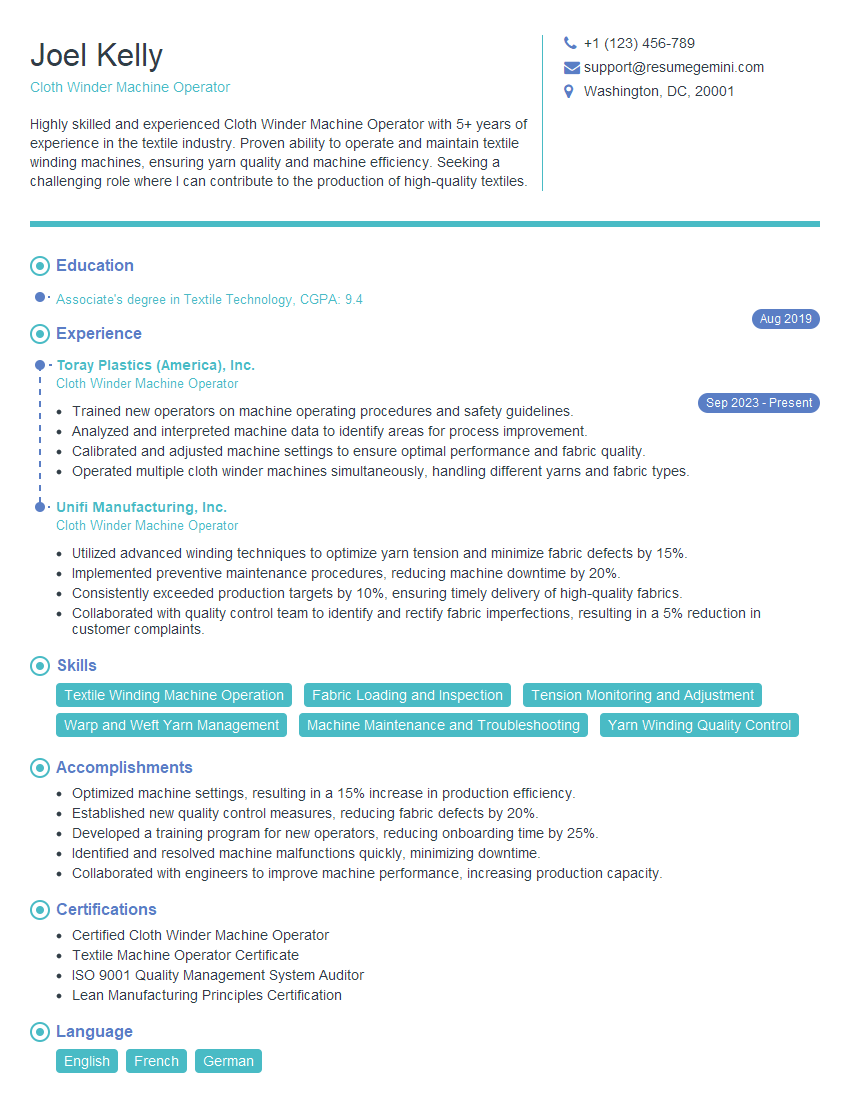

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Winder Machine Operator

1. Explain the importance of tension control in cloth winding?

Tension control is crucial in cloth winding as it directly affects the quality and efficiency of the winding process. Proper tension ensures:

- Uniform winding: Prevents loose or overly tight windings that can cause wrinkles or tears.

- Smooth operation: Reduces friction and wear on the machine.

- Increased productivity: Optimal tension allows for faster winding speeds without compromising fabric integrity.

2. Describe the different methods of tension control in cloth winding.

Constant tension control

- Maintains a consistent tension throughout the winding process.

- Suitable for delicate fabrics that require gentle handling.

Variable tension control

- Adjusts tension dynamically based on factors like fabric thickness and density.

- Ensures optimal tension for a wide range of fabrics.

Dancer roll tension control

- Uses a dancer roll to measure and adjust tension by sensing fabric slack.

- Provides precise tension control for high-speed winding.

3. What are the common faults that can occur in cloth winding and how do you troubleshoot them?

- Uneven winding: Check tension settings, alignment of guides, and fabric tension.

- Wrinkles and creases: Adjust tension, check fabric quality, and ensure the winding roller is free of debris.

- Telescoping: Ensure proper tension and alignment of the winding roller.

- Fabric breakage: Inspect tension settings, check for sharp edges or obstructions, and ensure the fabric is being guided correctly.

4. What is the purpose of a core tube in cloth winding, and what factors should be considered when selecting its size and material?

- Provides a rigid support for the wound fabric, ensuring a stable roll.

- Factors to consider:

- Diameter: Must accommodate the width of the fabric.

- Length: Determined by the required fabric quantity.

- Material: Cardboard, plastic, or metal, chosen based on durability, load capacity, and cost.

5. Describe the safety precautions that should be observed when operating a cloth winding machine.

- Wear appropriate safety gear: Gloves, safety glasses, and earplugs.

- Keep the work area clean and free of tripping hazards.

- Never operate the machine when it is not properly guarded.

- Inspect the machine regularly for any signs of damage or wear.

- Report any safety concerns or accidents to a supervisor immediately.

6. How do you ensure that the wound fabric meets customer specifications?

- Follow established winding parameters (tension, speed, core size).

- Inspect the wound fabric for defects, width, and length.

- Calibrate the machine regularly to maintain accuracy.

- Communicate with the customer if any adjustments to specifications are necessary.

7. What is the role of maintenance in cloth winding operations?

- Preventive maintenance: Regular cleaning, lubrication, and inspections to reduce breakdowns.

- Predictive maintenance: Monitoring machine performance to identify and address potential issues before they occur.

- Corrective maintenance: Repairing or replacing damaged or worn components to restore machine functionality.

8. How can you improve the efficiency of the cloth winding process?

- Optimize tension control to reduce downtime due to fabric breakage.

- Use automation and technology for faster winding and improved accuracy.

- Implement lean manufacturing principles to minimize waste and increase productivity.

- Train operators on best practices and troubleshooting techniques.

9. What is your approach to working as part of a team in a cloth winding environment?

- Communicate effectively with colleagues to ensure smooth coordination.

- Support team members by sharing knowledge and assisting with tasks.

- Respect diversity and work harmoniously with individuals from different backgrounds.

- Contribute to a positive and safe work environment by adhering to guidelines and reporting any concerns.

10. How do you stay updated on the latest developments in cloth winding technology?

- Attend industry events and conferences to learn about new machines and techniques.

- Read trade publications and online resources to stay informed about advancements.

- Engage with manufacturers and suppliers to receive updates on product enhancements.

- Seek opportunities for professional development and training to expand knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Winder Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Winder Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cloth Winder Machine Operator is responsible for operating a cloth winder machine to wind fabric onto rolls and ensure that the process meets quality standards. They may also be responsible for maintaining and troubleshooting the machine, as well as performing other tasks as assigned.

1. Load and operate the cloth winder machine

The Cloth Winder Machine Operator loads the cloth onto the machine and sets the machine to the correct settings to wind the fabric onto rolls. They must monitor the machine during operation to ensure that the fabric is being wound correctly and that the rolls are being produced to the correct specifications.

2. Inspect the fabric and rolls

The Cloth Winder Machine Operator inspects the fabric before it is wound onto the rolls to ensure that it is free of defects. They also inspect the rolls after they have been wound to ensure that they meet the correct specifications.

3. Maintain and troubleshoot the machine

The Cloth Winder Machine Operator is responsible for maintaining the cloth winder machine in good working order. They perform regular maintenance tasks such as cleaning and lubricating the machine. They also troubleshoot any problems that may occur with the machine.

4. Perform other tasks as assigned

The Cloth Winder Machine Operator may also be assigned other tasks, such as packaging and shipping the rolls of fabric.

Interview Tips

Here are some tips to help you ace your interview for a Cloth Winder Machine Operator position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the position. You can find information about the company on their website and in industry publications. You can also find information about the position in the job posting.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience operating a cloth winder machine. Be sure to highlight your skills and experience in your resume and cover letter. In your interview, be prepared to talk about your experience in detail. You should be able to provide specific examples of your work.

4. Be positive and enthusiastic

The interviewer will be looking for someone who is positive and enthusiastic about the position. Be sure to show your interest in the position and the company. You should also be enthusiastic about your ability to do the job.

5. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing a suit or business casual attire. You should also be well-groomed and have a neat appearance.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cloth Winder Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.